Food hyperpressure low-temperature sterilization method

An ultra-high pressure, food technology, applied in food preservation, food science, application, etc., can solve the problem of no food ultra-high pressure sterilization process conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

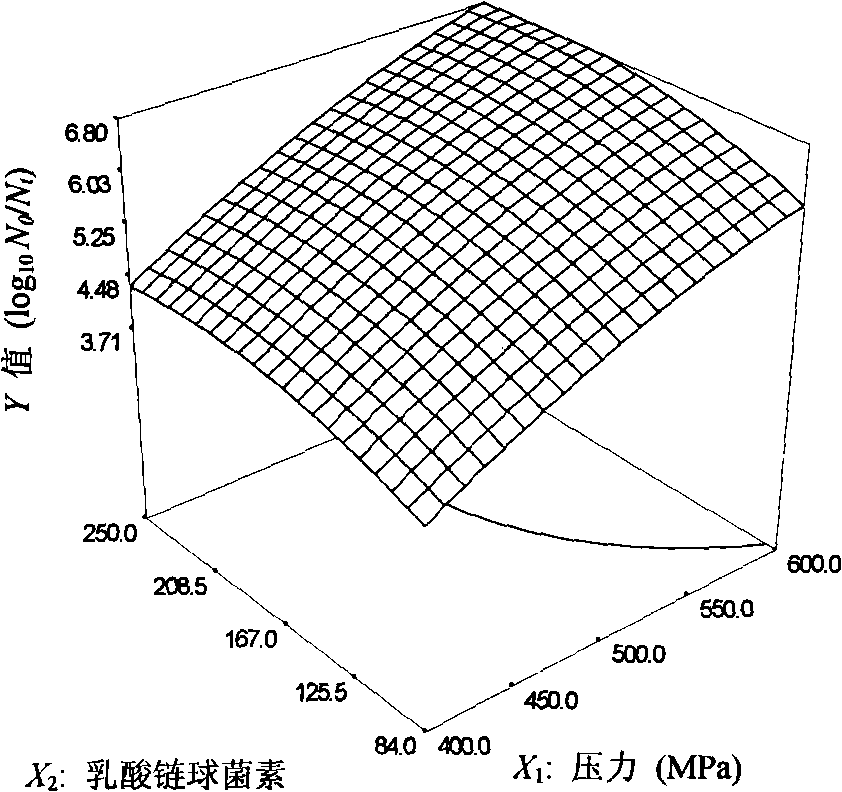

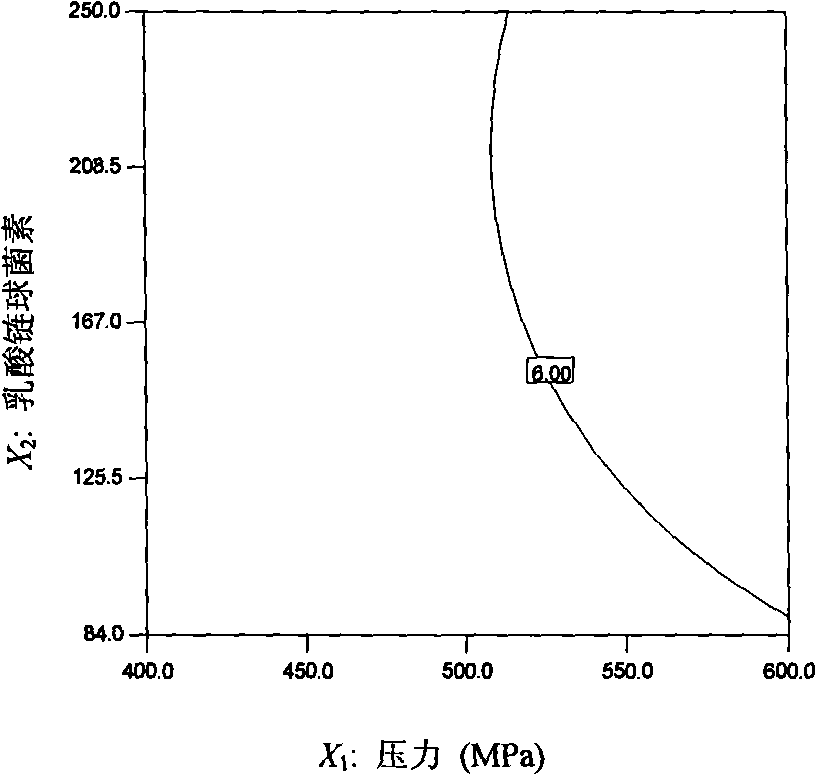

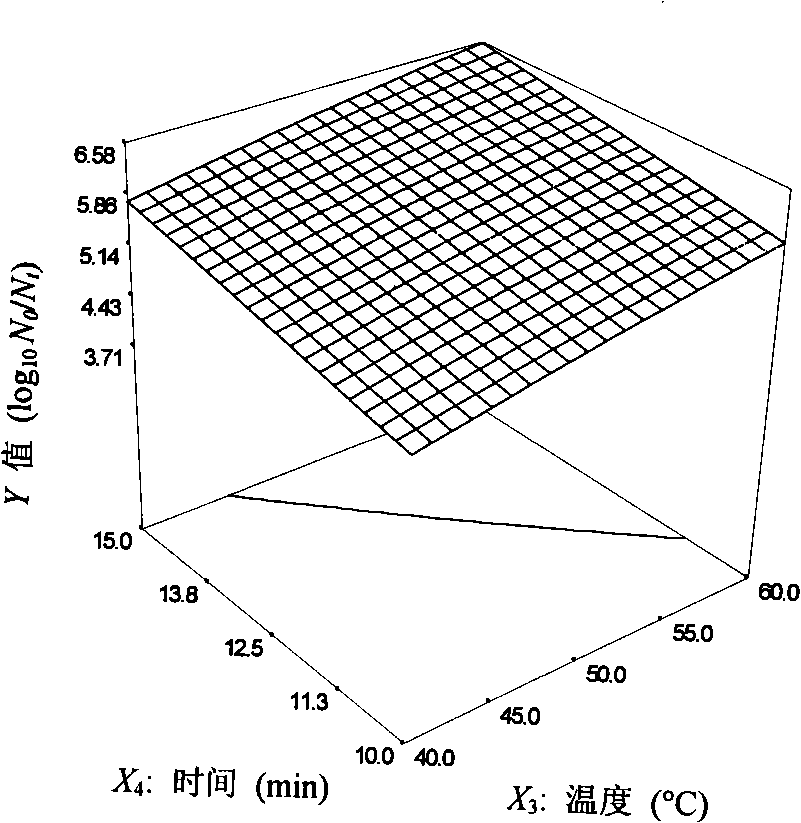

Method used

Image

Examples

Embodiment 1

[0068] Milk was used as raw material to inoculate Bacillus subtilis As1.1378 spores, Bacillus stearothermophilus As1.1865 spores, 213B spores, Bacillus cereus As1.1626 Staphylococcus aureus As1.1529, Salmonella typhimurium 1.1194 and Escherichia coli As1 .1671, adjust the concentration of bacterial cells so that the number in milk is (9.1±2.1)×10 6 cfu·ml -1Add nisin 140IU / ml, divide it into 100ml sterile plastic bottles, heat-seal (without leaving headspace), control the temperature of the high-pressure medium, and wait until the temperature of the sample and the high-pressure medium reach 54°C After equilibrium, pressurize at 569MPa for ultra-high pressure treatment for 15 minutes, and then immediately measure the number of microorganisms and nutritional components in the milk.

[0069] The loss rate of main nutrients in milk is less than 0.02%, and the total number of bacteria is 0cfu·ml -1 , after being stored at room temperature for 3 months, the total number of bacteri...

Embodiment 2

[0071] Milk was used as raw material to inoculate Bacillus subtilis As1.1378 spores, Bacillus stearothermophilus As1.1865 spores, 213B spores, Bacillus cereus As1.1626 Staphylococcus aureus As1.1529, Salmonella typhimurium 1.1194 and Escherichia coli As1 .1671, adjust the concentration of bacterial cells so that the number in milk is (9.1±2.1)×10 6 cfu·ml -1 Add nisin 300IU / ml, divide it into 100ml sterile plastic bottles, heat seal (without leaving headspace), control the temperature of the high-pressure medium, and wait until the temperature of the sample and the temperature of the high-pressure medium reach 66°C After equilibrium, pressurize at 669MPa for ultra-high pressure treatment for 12.4min, and then immediately measure the number of microorganisms and nutritional components in the milk.

[0072] The loss rate of main nutrients in milk is less than 0.04%, and the total number of bacteria is 0cfu·ml -1 , after being stored at room temperature for 3 months, the total ...

Embodiment 3

[0074] Soybean milk was used as raw material to inoculate Bacillus subtilis As1.1378 spores, Bacillus stearothermophilus As1.1865 spores, 213B spores, Bacillus cereus As1.1626 Staphylococcus aureus As1.1529, Salmonella typhimurium 1.1194 and Escherichia coli As1 .1671, adjust the concentration of bacterial cells so that the number in soybean milk is (9.1±2.1)×10 6 cfu·ml -1 Add nisin 210IU / ml, divide it into 100ml sterile plastic bottles, heat seal (without leaving headspace), control the temperature of the high-pressure medium, and wait until the temperature of the sample and the high-pressure medium reach 60°C After equilibration, pressurize at 612MPa for ultra-high pressure treatment for 16 minutes, and then immediately measure the number of microorganisms and nutritional components in soybean milk.

[0075] The loss rate of main nutrients in soybean milk is less than 0.03%, and the total number of bacteria is 0cfu·ml -1 , after being stored at room temperature for 3 mont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com