Ultrahigh-pressure low-temperature sterilization method for processed meat product and application thereof

A technology for ultra-high pressure sterilization and meat products, which is applied in application, food preservation, food preparation, etc. It can solve the problems of poor meat quality, poor meat fiber elasticity, loss of flavor and nutritional value, etc., and achieve long shelf life and high elasticity and chewing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

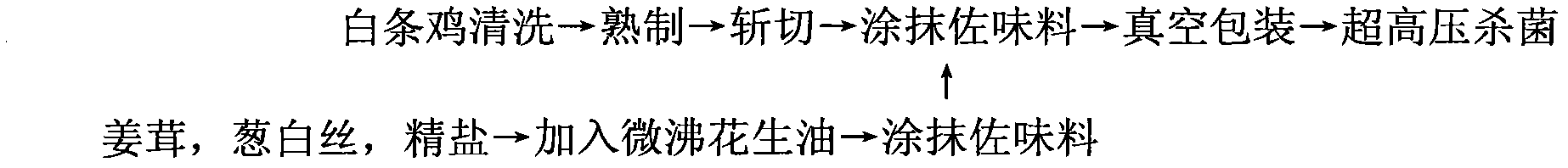

[0029] Example 1 "Bai Zhan Ji" meat product processed by ultra-high pressure and low temperature sterilization

[0030] The processing flow chart is attached figure 1 shown.

[0031] (1) Cook the cleaned white striped chicken according to the conventional process, then cut it into pieces, and apply the condiment, which is to add minced ginger, minced garlic, shredded scallion and refined salt to slightly boiling peanut oil;

[0032] (2) After smearing the condiment, put the chicken into a packaging container, vacuumize or heat and exhaust, and then seal it;

[0033] The packaging container can be made of high-pressure-resistant plastic, aluminum-plastic, paper-plastic and other flexible packaging materials that meet food requirements, and its shape can be round, square, triangular, rhombus, heart-shaped or other geometric shapes;

[0034] (3) Put the packaged conditioned meat products into the ultra-high pressure sterilization equipment for low-temperature sterilization.

...

Embodiment 2

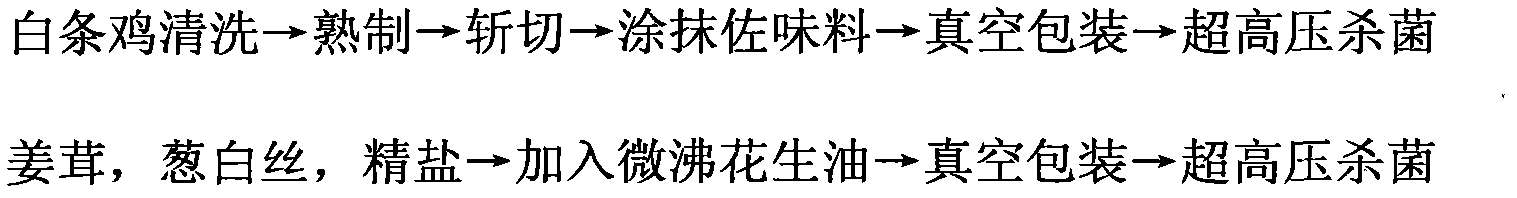

[0037] Example 2 "Bai Zhan Ji" meat products processed by ultra-high pressure and low temperature sterilization

[0038] The processing flow chart is attached figure 2 shown.

[0039] (1) Chopping and cutting the cleaned white-striped chicken according to conventional techniques;

[0040] Add minced ginger, scallion shreds, refined salt and other condiments to slightly boiling peanut oil;

[0041] (2) Pack the chopped chicken into a packaging container to vacuumize or heat and exhaust and then seal;

[0042] Put the smear seasoning into the packaging container and seal it after vacuumizing;

[0043] The packaging container can be made of high-pressure-resistant plastic, aluminum-plastic, paper-plastic and other flexible packaging materials that meet food requirements, and its shape can be round, square, triangular, rhombus, heart-shaped or other geometric shapes;

[0044] (3) Put the packaged chicken and condiments into the ultra-high pressure sterilization equipment for ...

Embodiment 3

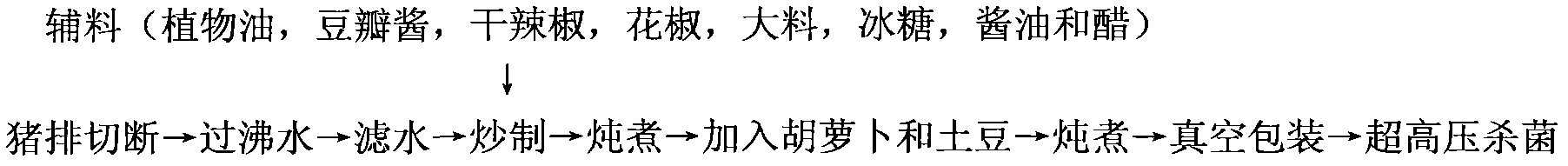

[0049] Example 3 Processing of Ultra-High Pressure and Low Temperature Sterilization "Potato Burned Pork Ribs"

[0050] 1. Raw materials

[0051] (1) Raw material: pork ribs

[0052](2) Accessories: potatoes, carrots, Pixian bean paste, dried chili, pepper, aniseed, salt, rock sugar, soy sauce, vinegar, etc.

[0053] 2. Processing technology

[0054] The flow chart is attached image 3 shown.

[0055] (1) Cook the pork chops and auxiliary materials according to conventional techniques;

[0056] In this example, cut the cleaned pork chops, add vegetable oil, bean paste, dried chili, Chinese prickly ash, aniseed, rock sugar, soy sauce, vinegar and other auxiliary materials after boiling, then add carrots and potatoes to stew , refer to the routine for the stewing time;

[0057] (2) Put the stewed potato spareribs into a packaging container, vacuumize or heat and exhaust, and then seal;

[0058] Or put the potato ribs into the packaging container while it is hot to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com