Vertical environment-friendly boiler for triple dedusting burning wood and biological particle fuel in boiler

A woody biomass and pellet fuel technology, applied in the field of boilers, can solve problems such as difficult large-scale, large excess air coefficient, and complex smoke and air system, and achieve the effects of inhibiting high-temperature degradation, fast combustion speed, and eliminating black smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

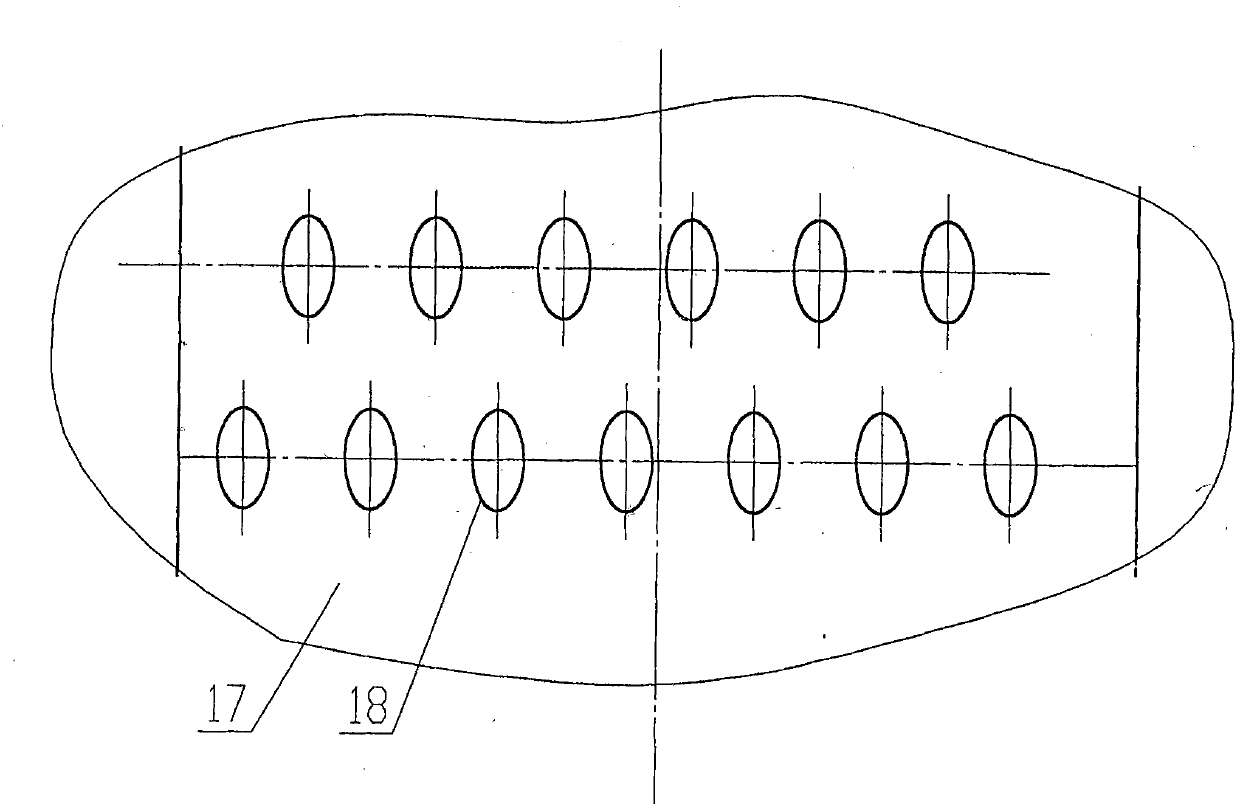

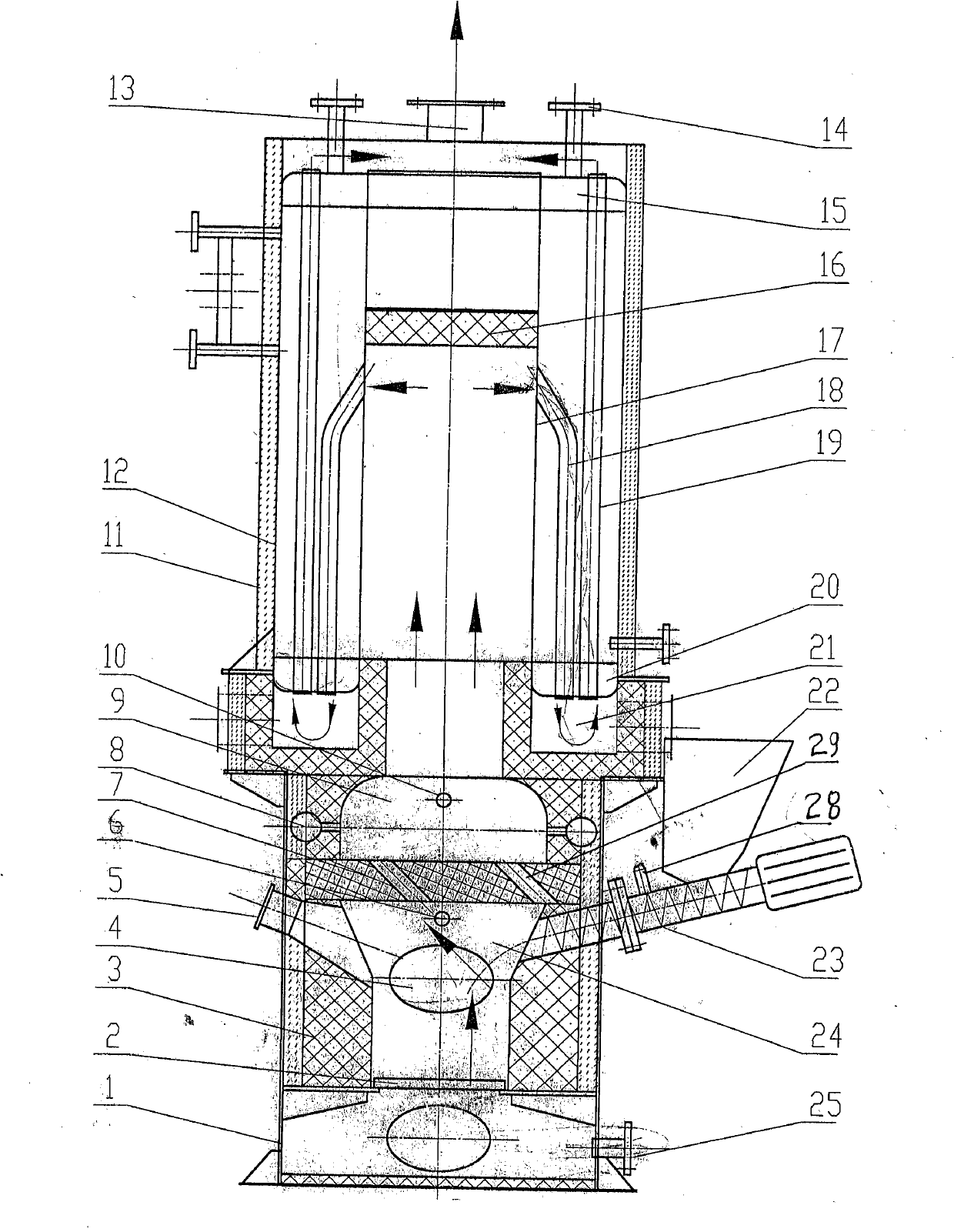

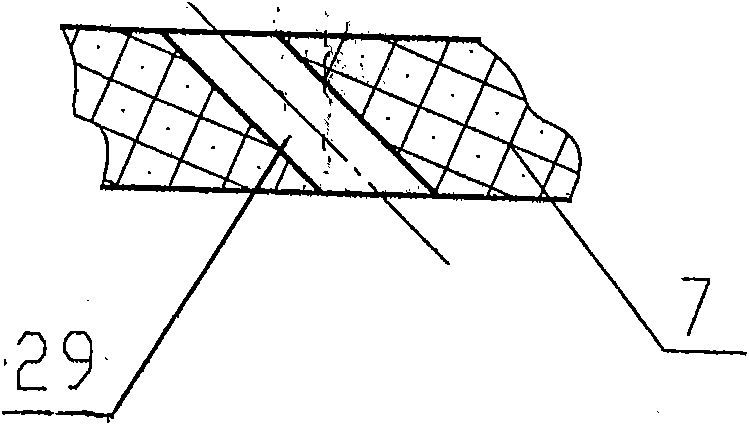

[0021] Refer to Figure 1 to Figure 6 The bottom of the boiler of the present invention is provided with a base 1, and above the base is an air chamber that also serves as a dust removal chamber. The upper end of the air chamber is provided with a grate 2, and there is a primary air inlet 25 for particulate fuel combustion under the grate. Above the grate is an insulating side wall 3 The enclosed carbon particle combustion gasification chamber 24 and gas combustion chamber 9. A stepless speed-regulating screw feed device 23 with a hopper 22 and a sowing and cooling air inlet 28 installed on the side wall of the furnace, a secondary air intake device 8 for fuel gas combustion installed on the side wall of the gas combustion section of the furnace, the furnace The door frame 26 of the tongue-and-groove type high-sealing positive pressure combustion furnace at the position of the upper air chamber and the furnace, the high-temperature resistant ceramic fiber rope 27 embedded in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com