Improved structure of steam electric iron

A technology for improving the structure and electric iron, which is applied in the direction of hand iron, washing device, textile and papermaking, etc., can solve the problems of increasing the degree of steam vaporization, complexity, and the power of electric heating tube cannot be made too large, and achieves simplified structure, production and installation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

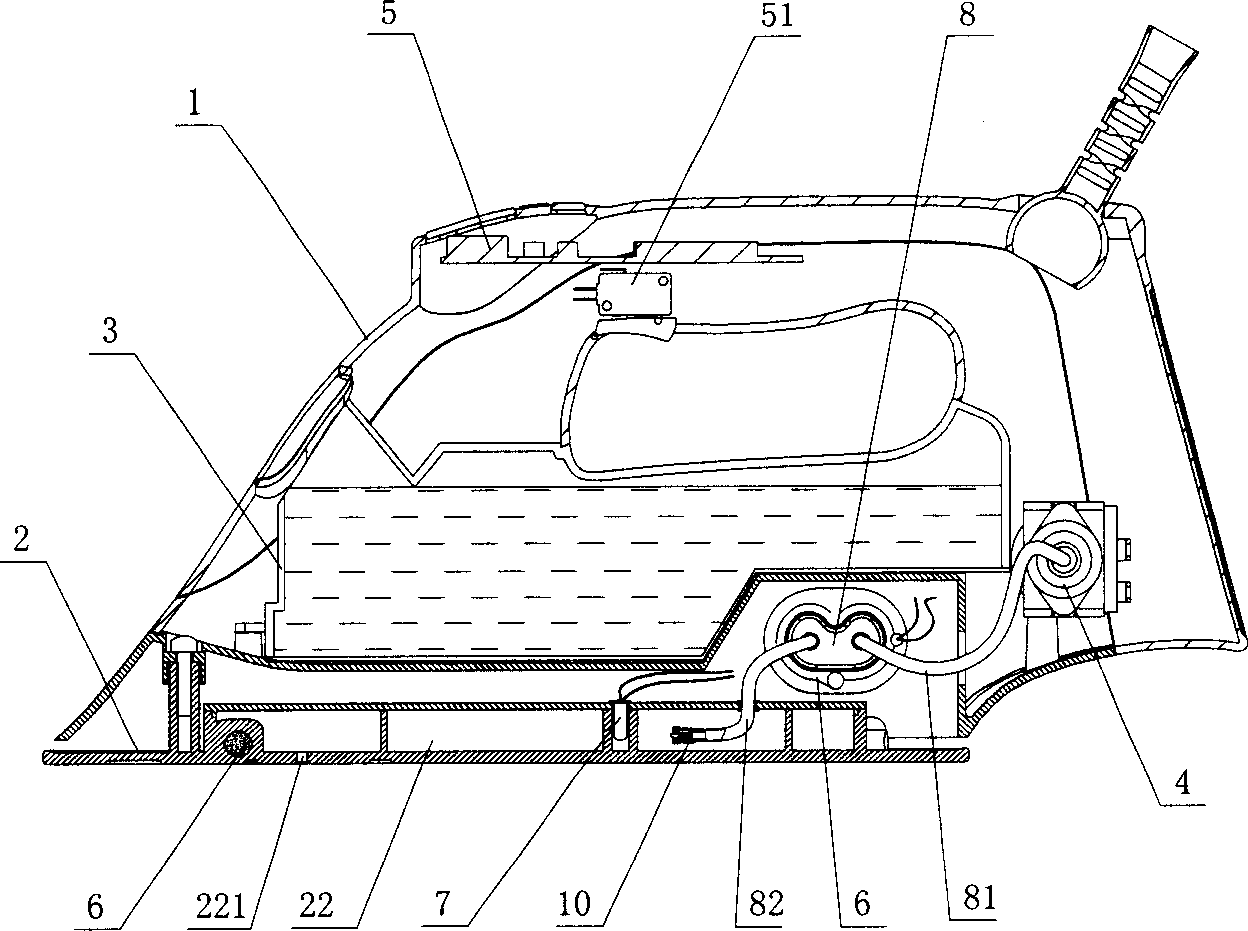

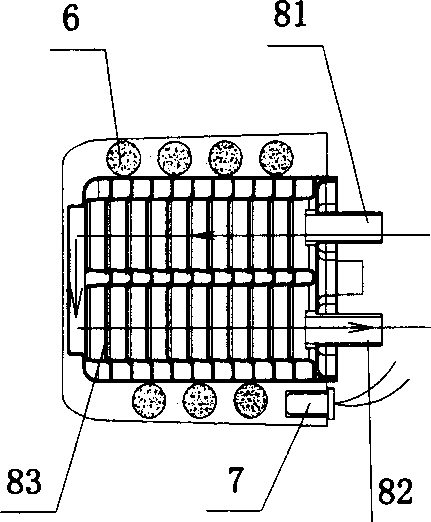

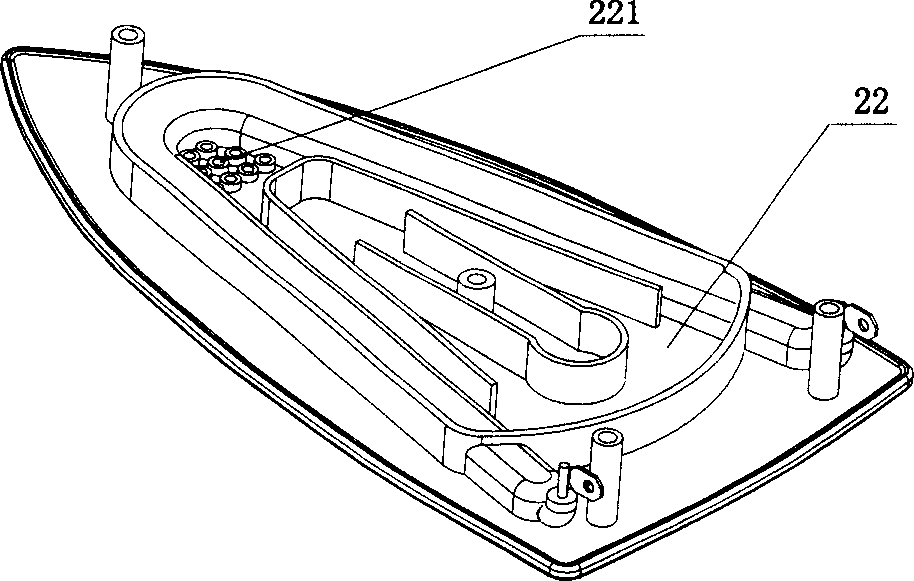

[0011] like figure 1 , figure 2 and image 3 Shown is an improved structure embodiment of the steam electric iron described in the present invention, including a soleplate 2 and a body, and the body includes a casing 1, a water tank 3, a water pump 4, a control unit 5, an electric heating tube 6 and a temperature sensor 7 and other main components. The bottom plate 2 is a double-layer structure, and is divided into an upper vaporization chamber 8 and a lower vaporization chamber 22. The lower vaporization chamber 22 is provided with an air injection port 221, and the upper vaporization chamber 8 is a heating chamber independent of the lower vaporization chamber 22. The upper vaporization chamber 8 is provided with a water inlet pipe 81 and an air outlet pipe 82, and the air outlet pipe 82 communicates with the lower vaporization chamber 22. The air outlet pipe 82 is provided with a pressure-adjustable one-way valve 10 at one end of the lower vaporization chamber 22, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com