Fluidized bed heating device as well as oil-containing kieselguhr serialization oil extraction equipment and oil extraction method

A technology of heating device and oil extraction equipment, applied in coil device, induction heating, petroleum industry and other directions, can solve the problems of pollution, reduce service life, secondary pollution, etc., and achieve the effect of ensuring performance and improving oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

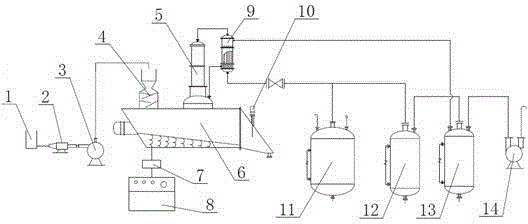

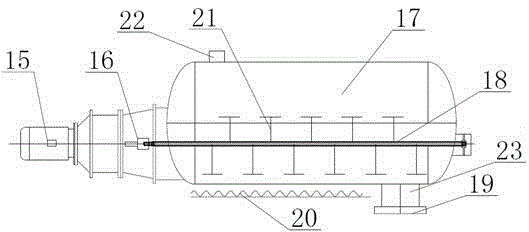

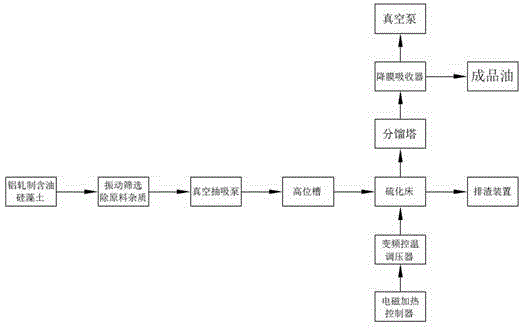

[0029] see figure 1 , an electromagnetic eddy current heating device for a fluidized bed of the present invention, comprising a fluidized bed and an electromagnetic heating controller 8 connected to the fluidized bed, the fluidized bed includes a fluidized bed body 17 and an agitating shaft 18 arranged inside the bed body, the agitating shaft 18 is equipped with a stirring blade 21, the left end of the stirring shaft 18 is connected with a reducer 16 and a motor 15 in turn, the reducer 16 is a cycloid reducer, and the upper left side of the fluidized bed body 17 is provided with Feed inlet 22, a discharge port 23 is provided on the lower right side of the fluidized bed body 17, a gate valve 19 is provided at the discharge port 23, and the discharge port 23 is connected with the slagging device 10, and the vulcanization The lower part of the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com