Novel steam generator

A steam generator, a new type of technology, applied in the direction of steam generation, steam generation method, wrinkle removal and flattening equipment, etc., can solve the problems of dripping water, limited degree of water vaporization, steam condensation, etc., to reduce the probability of dripping water and increase reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

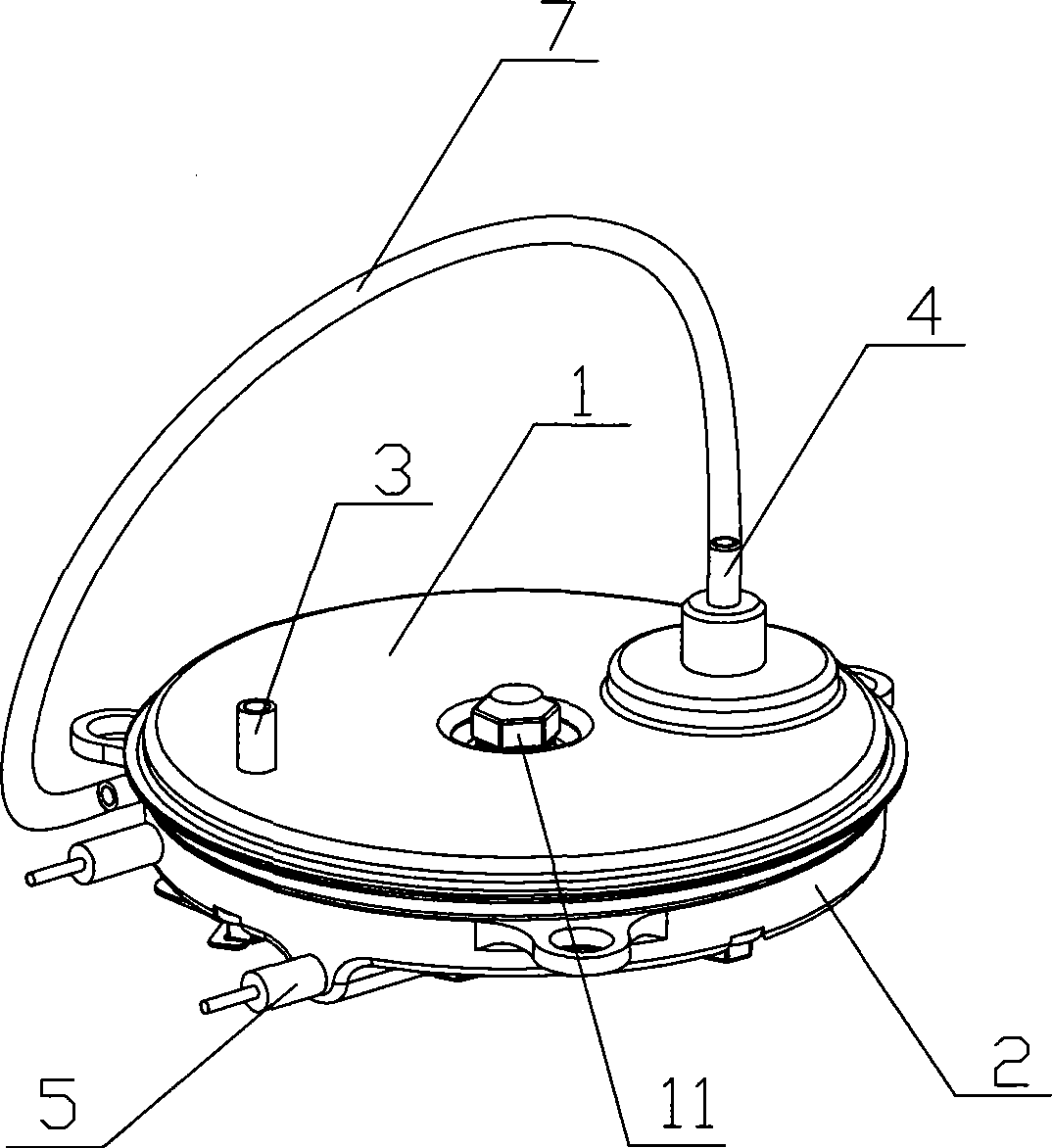

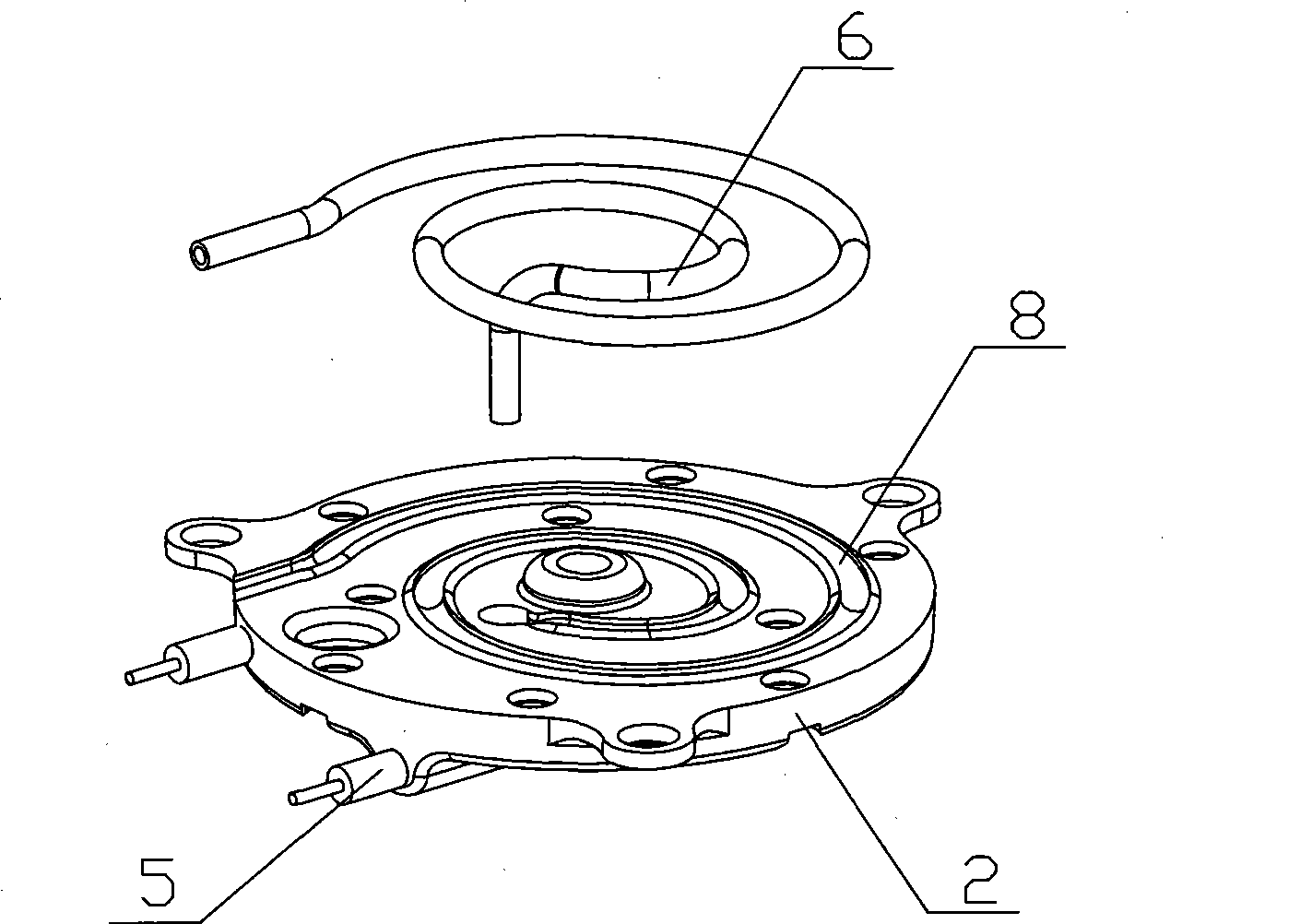

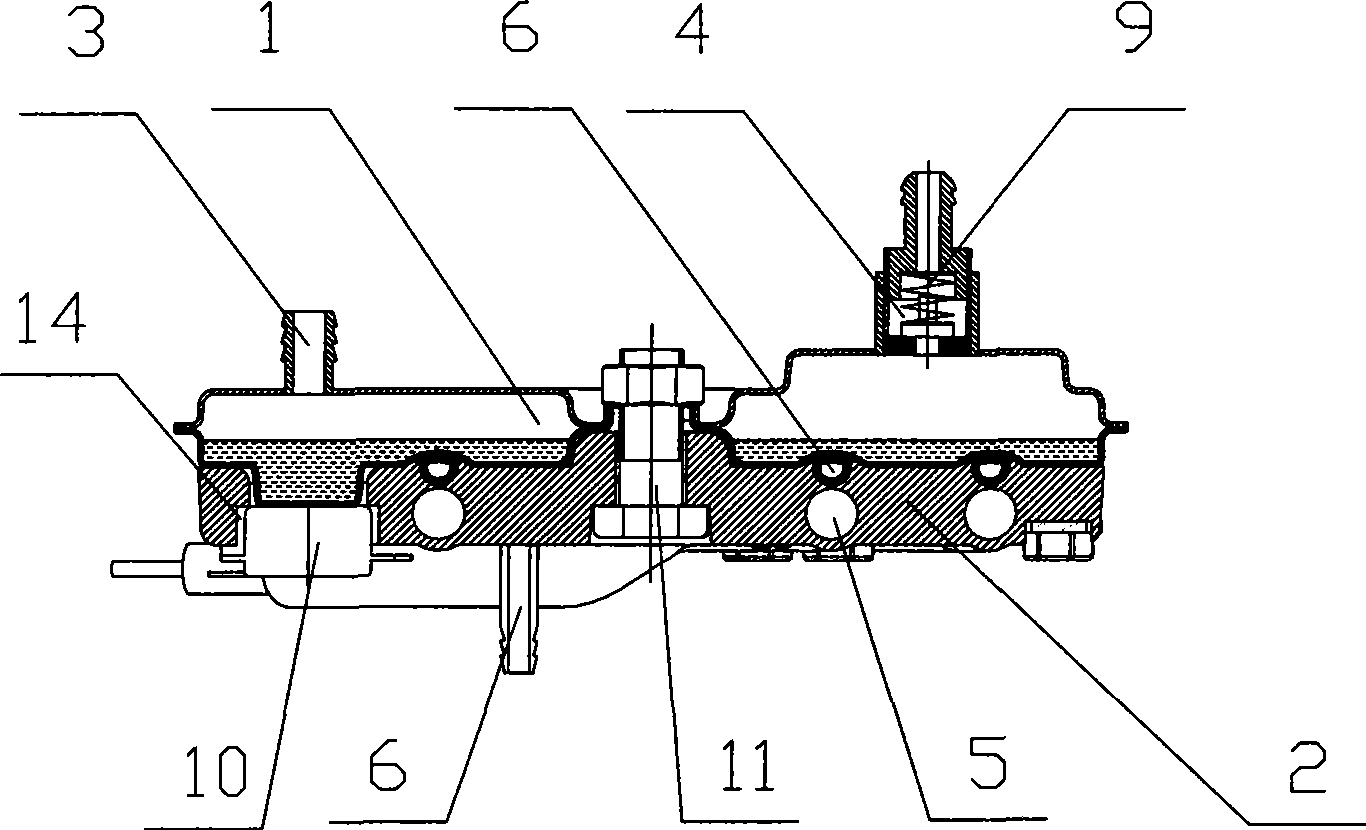

[0018] Such as figure 1 , figure 2 , image 3 As shown, a novel steam generator includes a pot body 1, a heating plate 2 connected with the pot body 1, the pot body 1 is provided with a water inlet 3 and a steam outlet 4, and the heating plate 2 is provided with The electric heating tube 5, the upper part of the electric heating tube 5 on the heating plate 2 is provided with a steam guiding pipe 6, and the steam guiding pipe 6 is connected with the steam outlet 4 through a hose 7. The electric heating tube 5 adopts a ring shape. An embedded groove 8 is arranged on the upper part of the electric heating tube 5 on the heating plate 2 , and the steam guiding pipe 6 is arranged in the embedded groove 8 . The steam guiding pipe 6 and the caulking groove 8 are ring-shaped. The steam outlet 4 is provided with a one-way valve 9 . The heating plate 2 is provided with a thermostat installation through groove 14, and the thermostat installation through groove 14 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com