Method for preparing superfine spherical iron nitride powder

A technology of iron nitride and spherical shape, which is applied in the direction of nitrogen-metal/silicon/boron binary compounds, etc., can solve the problems of poor stability, complicated process, and low powder sphericity, and achieve high saturation magnetization, fine and uniform particle size, Reduces the effect of oxidation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

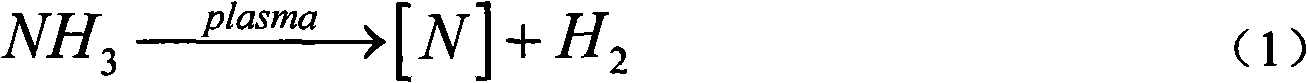

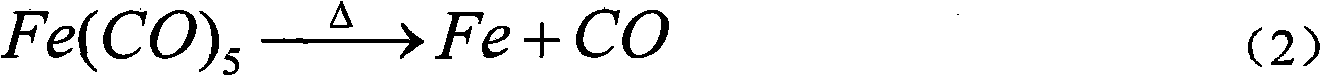

[0020] Example 1: Preparation of ultrafine spherical iron nitride powder with an average particle diameter of 150nm

[0021] Using carbonyl iron liquid and ammonia gas as raw materials, the stable radio frequency (RF) plasma power is 60KW, the flow rate of argon working gas is 45 slpm, the flow rate of argon protective gas is 150 slpm, and the system negative pressure is 220 mm Hg. Send carbonyl iron liquid vapor with a flow rate of 5 slpm and ammonia gas with a flow rate of 30 slpm into the high-temperature plasma. The carbonyl iron liquid vapor is decomposed and nitrogen ions are nitrided to form iron nitride powder, which is collected to obtain ultrafine spherical particles with an average particle size of 150 nm. Iron nitride powder.

example 2

[0022] Example 2: Preparation of ultrafine spherical iron nitride powder with an average particle size of 50nm

[0023] Using carbonyl iron liquid and ammonia as raw materials, the stable radio frequency (RF) plasma power is 55KW, the flow rate of argon working gas is 30 slpm, the flow rate of argon protective gas is 150 slpm, and the system negative pressure is 200 mm Hg. Send carbonyl iron liquid vapor with a flow rate of 3 slpm and ammonia gas with a flow rate of 40 slpm into the high-temperature plasma. The carbonyl iron liquid vapor is decomposed and nitrogen ions are nitrided to form iron nitride powder, which is collected to obtain ultrafine spherical particles with an average particle size of 50 nm. Iron nitride powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com