Method for preparing core-shell structured SiO2/Fe3O4 compound magnetic particle

A core-shell structure and particle technology, which is applied in the field of preparation of core-shell structure SiO2/Fe3O4 particles, can solve the problems of magnetic core agglomeration, small output, and difficulty in large-scale production, and achieve clear shell core structure, obvious dispersion, The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Measure 112ml of ethylene glycol as a solvent, dissolve 3.78g of ferric chloride and 10.08g of sodium acetate in ethylene glycol, stir at high speed with magnetic force for 10 minutes, then add an appropriate amount of polyethylene glycol (molecular weight 1500) and continue stirring After 30 minutes a mixed solution was obtained. Then pour it into a polytetrafluoroethylene-lined high-pressure reactor, seal the reactor and place it in an oven, heat it to 180°C and keep it warm for 9 hours. The precipitate was washed three times with deionized water until the pH of the solution was 7, then washed twice with ethanol, and dried in an oven at 60°C for 6 hours to obtain black Fe 3 o 4 powder.

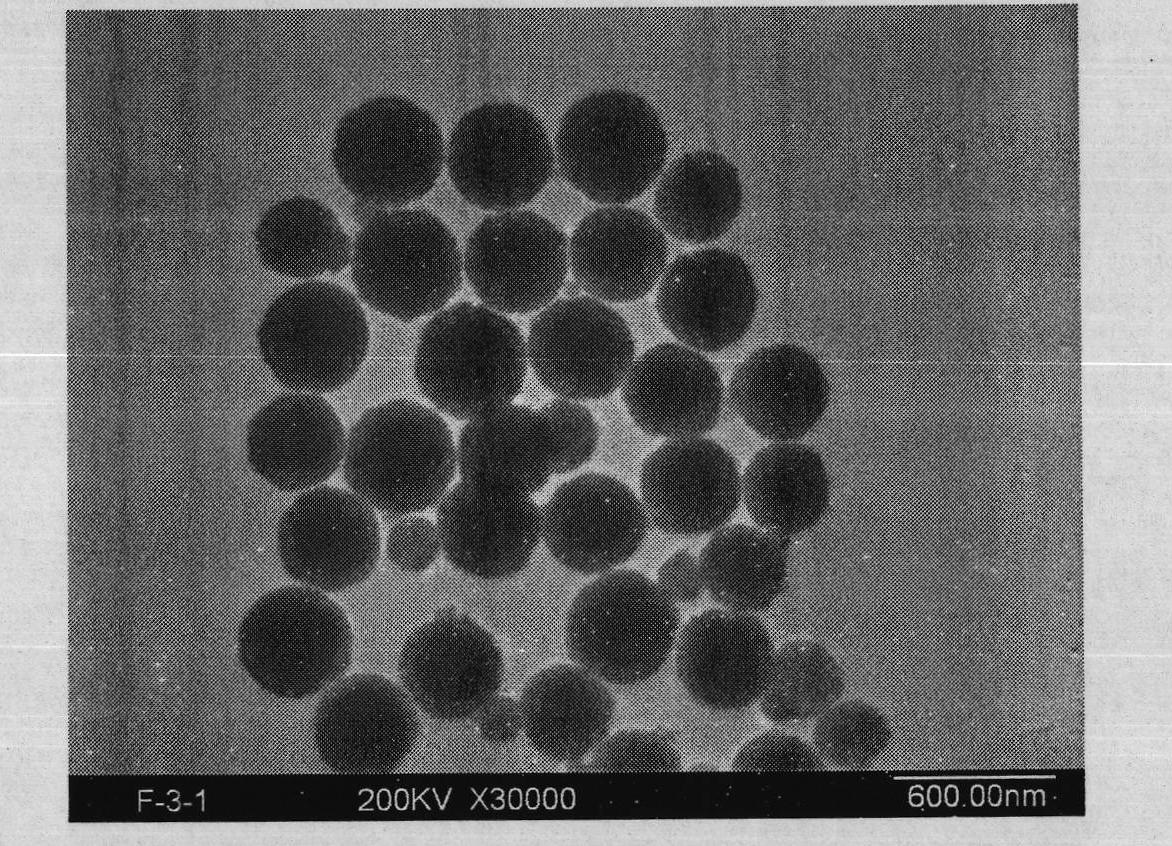

[0018] Synthetic Fe 3 o 4 mother core see figure 1 , the particle size is about 400nm.

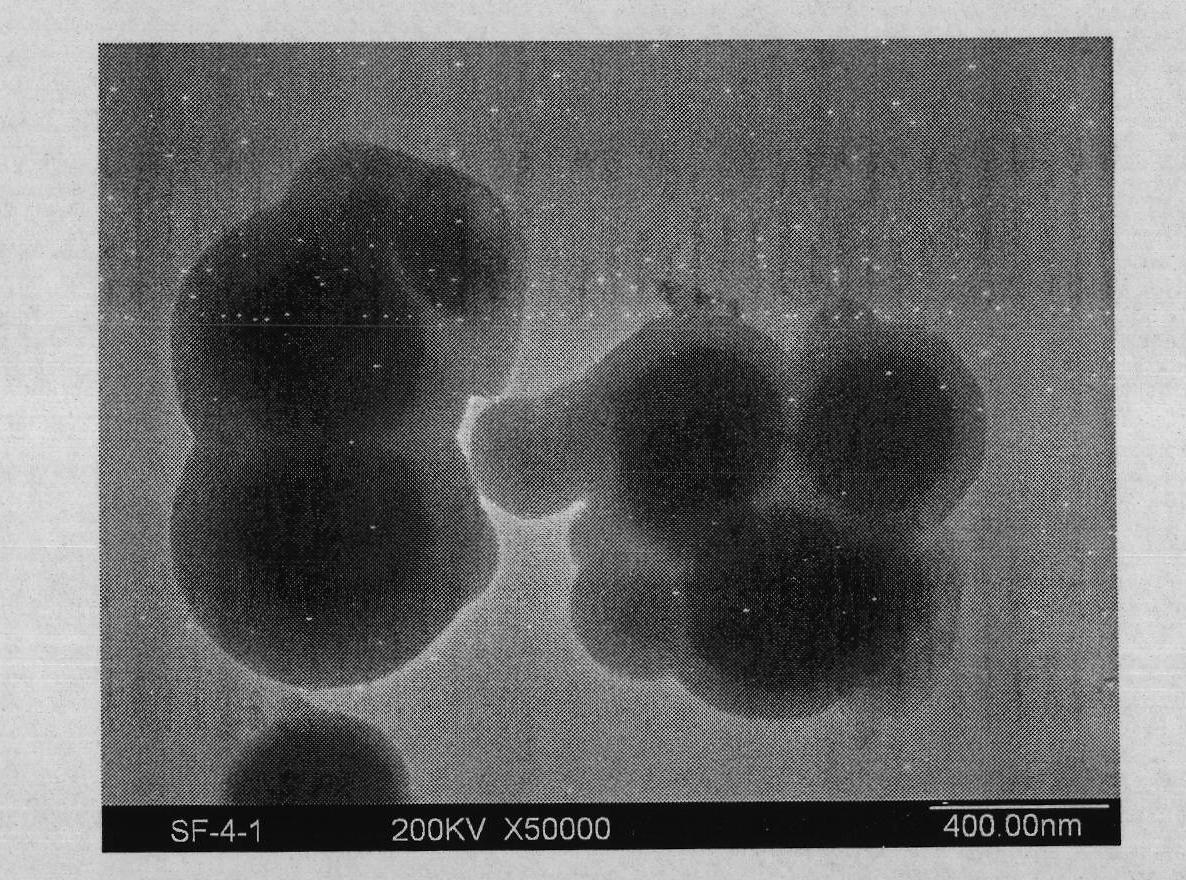

[0019] (2) At room temperature, mix 90ml of absolute ethanol, 22.5ml of deionized water, and 0.3g of the above-mentioned Fe 3 o 4 Powder, mixed with 0.5g sodium dodecylbenzene sulfonat...

Embodiment 2

[0022] Change the consumption of strong ammonia water to be 0.315ml, and the consumption of other medicines and operation steps are the same as embodiment 1.

Embodiment 3

[0024] Change the consumption of concentrated ammonia water to be 1.26ml, and the consumption of other medicines and operation steps are the same as embodiment 1.

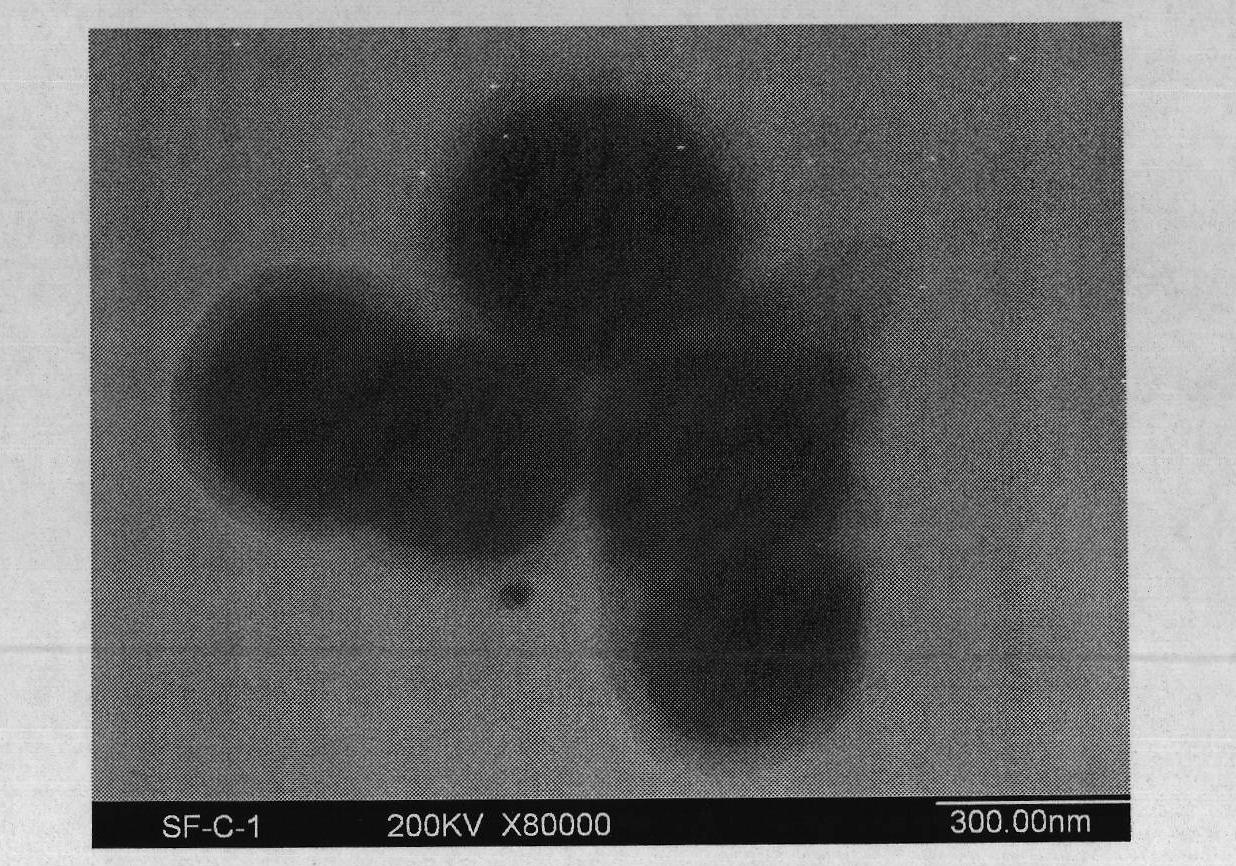

[0025] Synthetic SiO 2 / Fe 3 o 4 Particles with shell core structure see image 3 , SiO 2 The thickness of the shell layer is about 40 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com