Electrodynamic method for removing fluorine contaminant in soil

An electrokinetic and pollutant technology, applied in the restoration of polluted soil, etc., can solve the problems of soil pH value change, endangering the security of soil ecosystem, etc., to reduce electrochemical polarization, avoid the reduction of desorption effect, reduce The effect of small concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

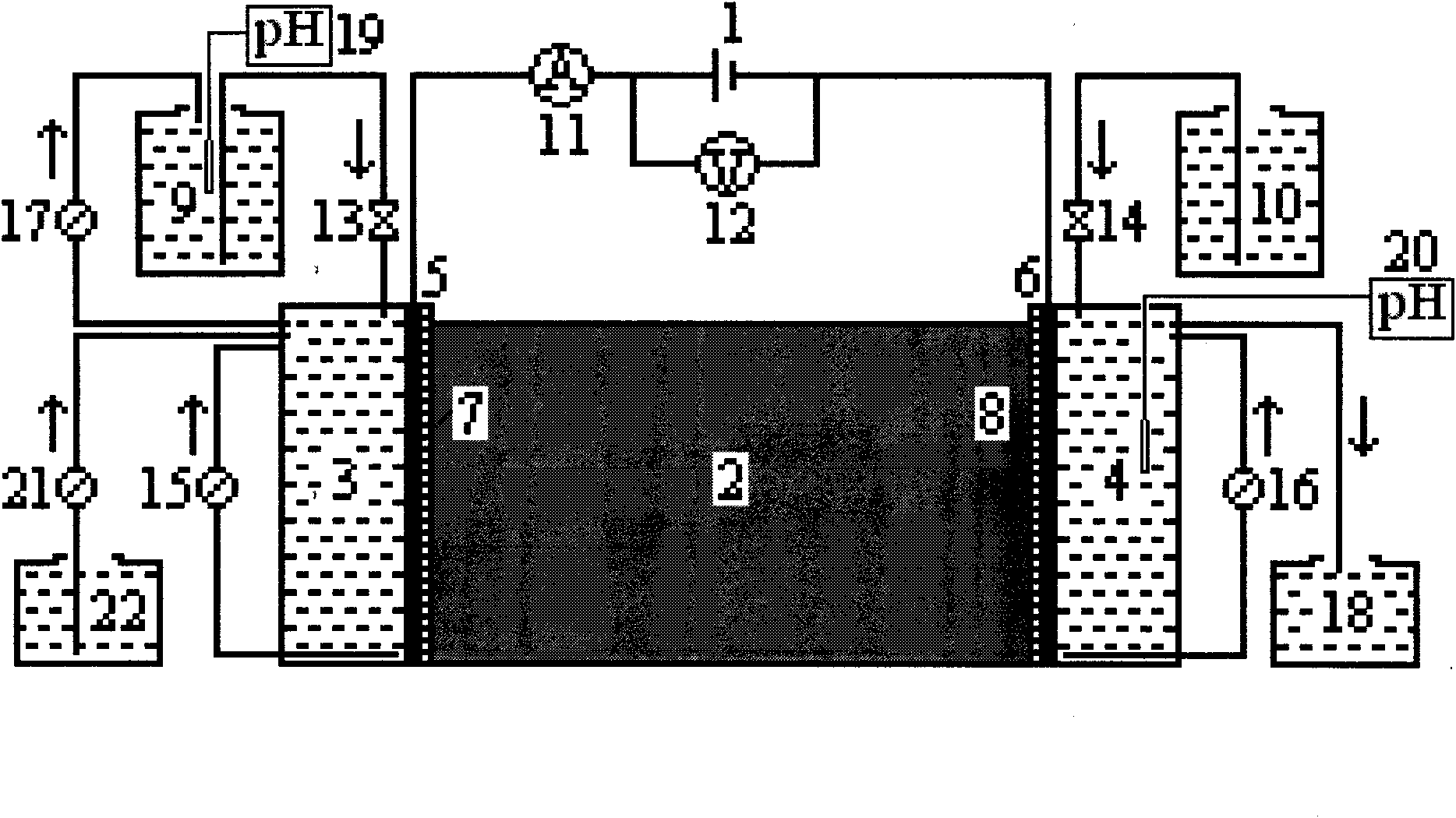

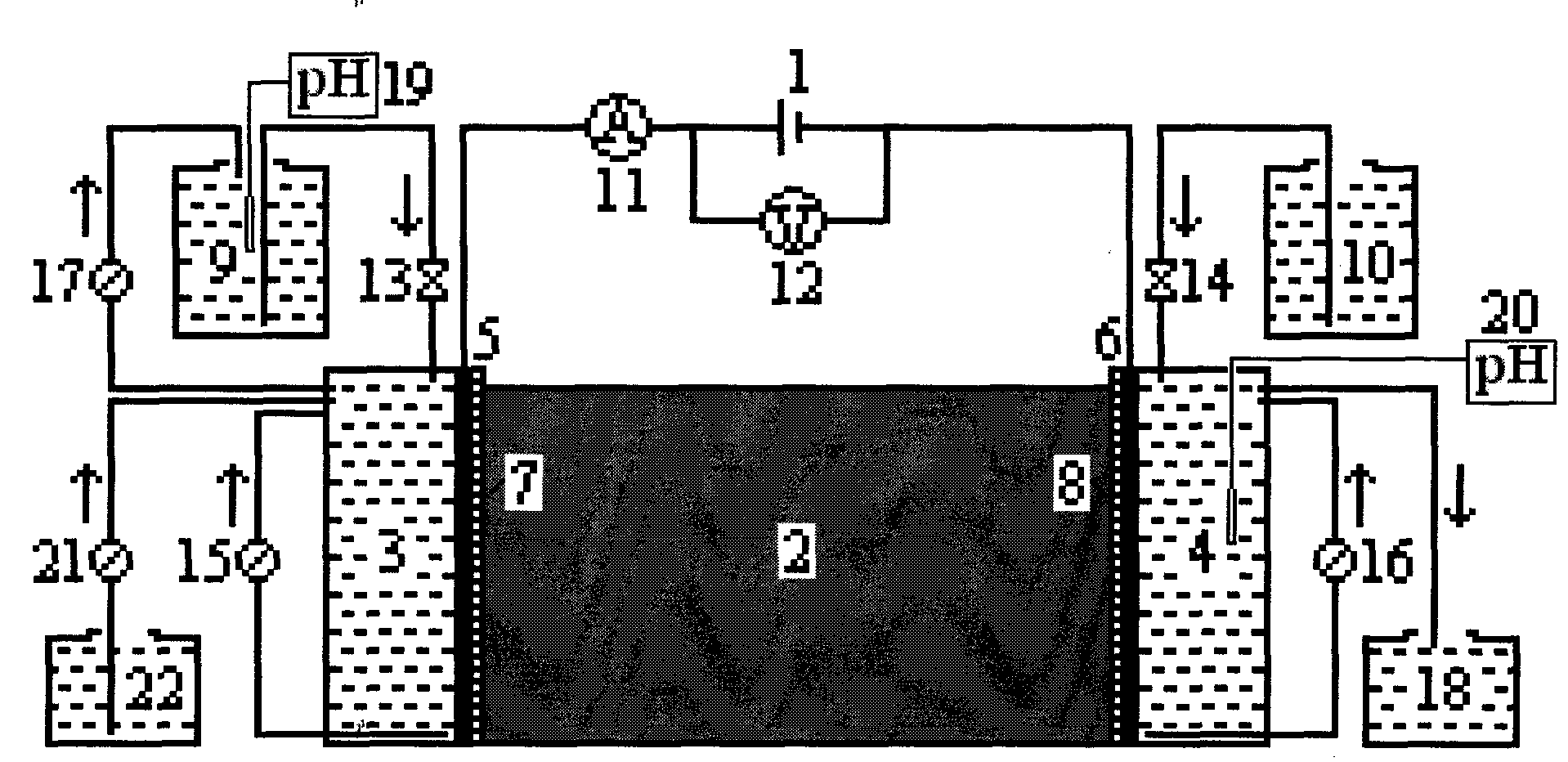

[0016] Embodiment 1 adopts such as figure 1 The electrokinetic device shown performs the removal process of fluorine pollutants in soil. The positive pole of the regulated DC power supply 1 is connected to the anode 5 through a wire, and the negative pole is connected to the cathode 6 . The electrolytic cell 2 is placed horizontally, and the anode chamber 3 and the cathode chamber 4 are respectively arranged at two ends of the electrolytic cell 2 . The anode 5 is placed in the anode chamber 3, the cathode 6 is placed in the cathode chamber 4, the anion exchange membrane 7 is placed between the anode and the polluted soil, and the alkali-resistant filter membrane 8 is placed between the polluted soil and the cathode. The anolyte circulates in the loop formed by the anode chamber 3, the transfer pump 15 and the conduit, so that the anolyte is mixed evenly; the anolyte storage chamber 9, the flow regulating valve 13, the anode chamber 3, and the transfer pump 17 form a loop thro...

Embodiment 2

[0019] The structure of the electrokinetic device used is the same as in Example 1.

[0020] Weigh 2000.0g of contaminated soil with a pH value of 7.6 and a fluorine content of 1382mg / kg, adjust the soil moisture content to 40%, and place it in an electrolytic cell. The anode electrolyte uses deionized water, and no sodium acetate solution is added during the restoration process. Its pH value, the initial electrolyte in the cathode chamber also uses deionized water, and does not add acetic acid to control its pH value during the repair process; the circulation flow rate of the electrolyte in the bipolar chamber is 3500ml / h, and the electric field strength is 1V / cm. After 240h of treatment, the fluoride ion The residual fluorine content in the soil was determined by selective electrode method to be 635mg / kg, the removal rate was 54%, the soil pH value at the anode end was 8.4, and the soil pH value at the cathode end was 12.1.

Embodiment 3

[0022] The structure of the electrokinetic device used is the same as in Example 1.

[0023]Replace the anion-exchange membrane 7 with an acid-resistant filter membrane, weigh 2000.0 g of polluted soil with a pH value of 7.6 and a fluorine content of 1382 mg / kg, adjust the soil moisture content to 40%, place it in an electrolytic cell, and use anolyte to remove Ionized water, sodium acetate solution is not added to adjust its pH value during the restoration process, deionized water is also used for the initial electrolyte in the cathode chamber, and acetic acid is not added to control its pH value during the repair process; the circulation flow rate of the electrolyte in the bipolar chamber is 3500ml / h, and the electric field The strength is 1V / cm, after 240h of treatment, the fluorine content of the soil measured by the fluoride ion selective electrode method is 1256mg / kg, the removal rate is 9.1%, the pH value of the soil at the anode end is 2.4, and the pH value of the soil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com