Fast curing epoxy resin system for blades of wind driven generator and preparation method thereof

An epoxy resin system and wind power generator technology, applied in the field of fast-curing epoxy resin system and its preparation, can solve the problems affecting the efficiency and output of blade production, short manufacturing process time, long gel time, etc., and achieve improvement International competitiveness, shorter gel time, effect of short gel time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

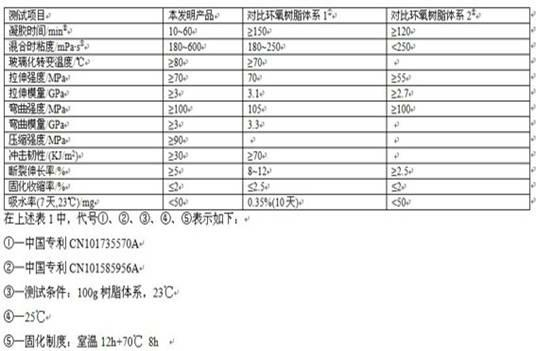

Image

Examples

Embodiment 1

[0047] Formula (parts by weight)

[0048] Raw materials for the resin part

[0049] epoxy resin

Bisphenol A type epoxy resin E-51

60 copies

Bisphenol F type epoxy resin

25 copies

Thinner

1,6-Hexanediol diglycidyl ether

15 copies

[0050] Raw materials for curing agent

[0051] High activity fatty amine curing agent

Polyetheramine T403

60 copies

trimethylhexamethylenediamine

15 copies

High activity alicyclic amine curing agent

10 copies

curing accelerator

15 copies

[0052] Preparation:

[0053] (1) Weigh the raw materials of the resin part and the curing agent part according to the above components and contents; and prepare the reaction kettle;

[0054] (2) Prepare the resin part and the curing agent part separately;

[0055] ① Resin part: Add the raw materials of the resin part into the reaction kettle, raise th...

Embodiment 2

[0061] Formula (parts by weight)

[0062] Raw materials for the resin part

[0063] epoxy resin

Bisphenol A type epoxy resin E-51

80 copies

Thinner

1,6-Hexanediol diglycidyl ether

20 copies

[0064] Raw materials for curing agent

[0065] High activity fatty amine curing agent

Polyetheramine D230

55 copies

m-xylylenediamine

20 copies

High activity alicyclic amine curing agent

10 copies

curing accelerator

Benzyldimethylamine

15 copies

[0066] Preparation:

[0067] (1) Weigh the raw materials of the resin part and the curing agent part according to the above components and contents; and prepare the reaction kettle;

[0068] (2) Prepare the resin part and the curing agent part separately;

[0069] ①Resin part: Add the raw materials of the resin part into the reaction kettle, raise the temperature to 45°C, continue to stir until the mixture is ev...

Embodiment 3

[0075] Formula (parts by weight)

[0076] Raw materials for the resin part

[0077] epoxy resin

Bisphenol A type epoxy resin E-51

75 copies

Thinner

1,4-Butanediol diglycidyl ether

25 copies

[0078] Raw materials for curing agent

[0079] High activity fatty amine curing agent

Polyetheramine D230

60 copies

Tetraethylenepentamine

10 copies

High activity alicyclic amine curing agent

10 copies

curing accelerator

20 copies

[0080] Preparation:

[0081] (1) Weigh the raw materials of the resin part and the curing agent part according to the above components and contents; and prepare the reaction kettle;

[0082] (2) Prepare the resin part and the curing agent part separately;

[0083] ①Resin part: Add the raw materials of the resin part into the reaction kettle, raise the temperature to 65°C, and continue to stir until the mixture is ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gel time | aaaaa | aaaaa |

| Gel time | aaaaa | aaaaa |

| Gel time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com