Technology for synthesizing bisquaternary ammonium salt slow-breaking quick-setting asphalt emulsifier

A technology of asphalt emulsifier and double quaternary ammonium salt, which is applied in chemical instruments and methods, chemical/physical processes, building components, etc., can solve problems such as little room for improvement, limited source of emulsifier raw materials, complicated process, etc., to achieve Uniform and fine asphalt emulsion particles, slow cracking and fast setting performance, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

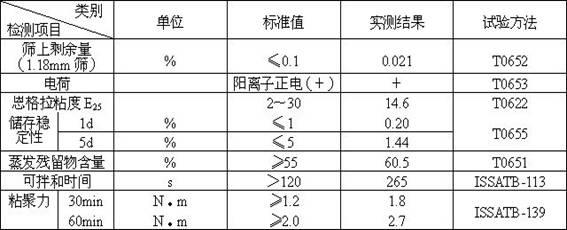

Embodiment 1

[0020] Preparation of emulsifier: 16.3g octadecyl-1,3-propylenediamine, 7.0g oleic acid, 7.4g cinnamic acid, 1.0g p-toluenesulfonic acid, 20g xylene were added to the reaction vessel, Stir and reflux reaction at 125°C for 4 hours, distill off the xylene, cool down to 65°C, add 20g of isopropanol to obtain the amide intermediate;

[0021] Mix 5.1g of triethylamine and 5g of concentrated hydrochloric acid uniformly at 40°C, then dropwise add 4.6g of epichlorohydrin into the reaction vessel, stir and react at 45°C for 4h, cool to room temperature, and obtain the quaternary ammonium salt intermediate;

[0022] Add the quaternary ammonium salt intermediate prepared above dropwise to the amide intermediate prepared above at 80-85°C, and stir and react at this temperature for 4 hours to obtain a double quaternary ammonium salt type cationic asphalt emulsifier product.

[0023] Preparation of emulsifier aqueous solution: Dissolve 2.0g of the emulsifier in 100g of warm water, heat the ...

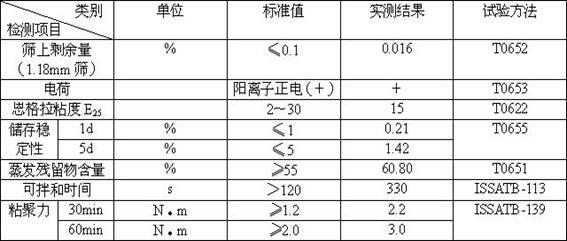

Embodiment 2

[0032] Emulsifier preparation: Add 13.5g octadecylamine, 5.8g maleic acid, 5.0g lauric acid, 1.0g p-toluenesulfonic acid, 20g xylene into the reaction vessel, and stir and reflux at 110°C for 4h Distill out xylene, lower the temperature to 65°C, add 20g of isopropanol to obtain the amide intermediate;

[0033] Mix 15g of octadecyldimethylamine and 5g of concentrated hydrochloric acid at 45°C, then drop 4.6g of epichlorohydrin into the reaction vessel, react at 50-55°C for 4h, cool to room temperature, and obtain quaternary ammonium salt Intermediate;

[0034] The quaternary ammonium salt intermediate prepared above was added dropwise to the amide intermediate prepared above at 80-85°C, and stirred and reacted at this temperature for 4 hours to obtain a double quaternary ammonium salt type cationic asphalt emulsifier product.

[0035] Preparation of emulsifier aqueous solution: Add 2.0g of the emulsifier into 100g of hot water at 65-80°C. After the emulsifier is dissolved, adj...

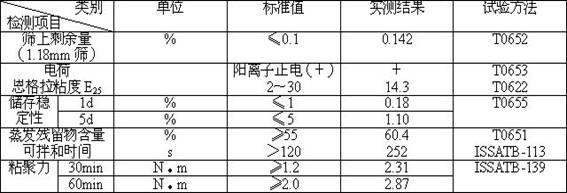

Embodiment 3

[0040] Preparation of emulsifier: 16.3g of N-octadecylpropylenediamine, 9g of abietic acid, 5.7g of stearic acid, 1.0g of p-toluenesulfonic acid, and 20g of trimethylbenzene were added to the reaction vessel and refluxed at 140°C After reacting for 4 hours, trimethylbenzene was distilled off, the temperature was lowered to 65°C, and 20 g of isopropanol was added to obtain the amide intermediate;

[0041] Mix 9g of octadecyldimethylamine, 2g of triethylamine and 5g of concentrated hydrochloric acid at 40°C, then dropwise add 4.6g of epichlorohydrin into the reaction vessel, stir and react at 45-50°C for 4h to obtain quaternary Ammonium salt intermediate;

[0042]Add the quaternary ammonium salt intermediate prepared above dropwise to the amide intermediate prepared above at 75~80°C, and stir and react at this temperature for 4 hours to obtain the double quaternary ammonium salt type cationic asphalt emulsifier product.

[0043] Preparation of emulsifier aqueous solution: Add 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com