High impact-resistant epoxy resin filling adhesive and preparation method thereof

A kind of epoxy resin, high impact resistance technology, used in epoxy resin glue, novolac epoxy resin adhesive, adhesive and other directions, can solve the problems of large compression modulus, poor heat resistance, low thermal deformation temperature and so on , to achieve the effect of improving impact resistance flexibility, compressive modulus and compressive strength, increasing curing speed, and low exothermic peak temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

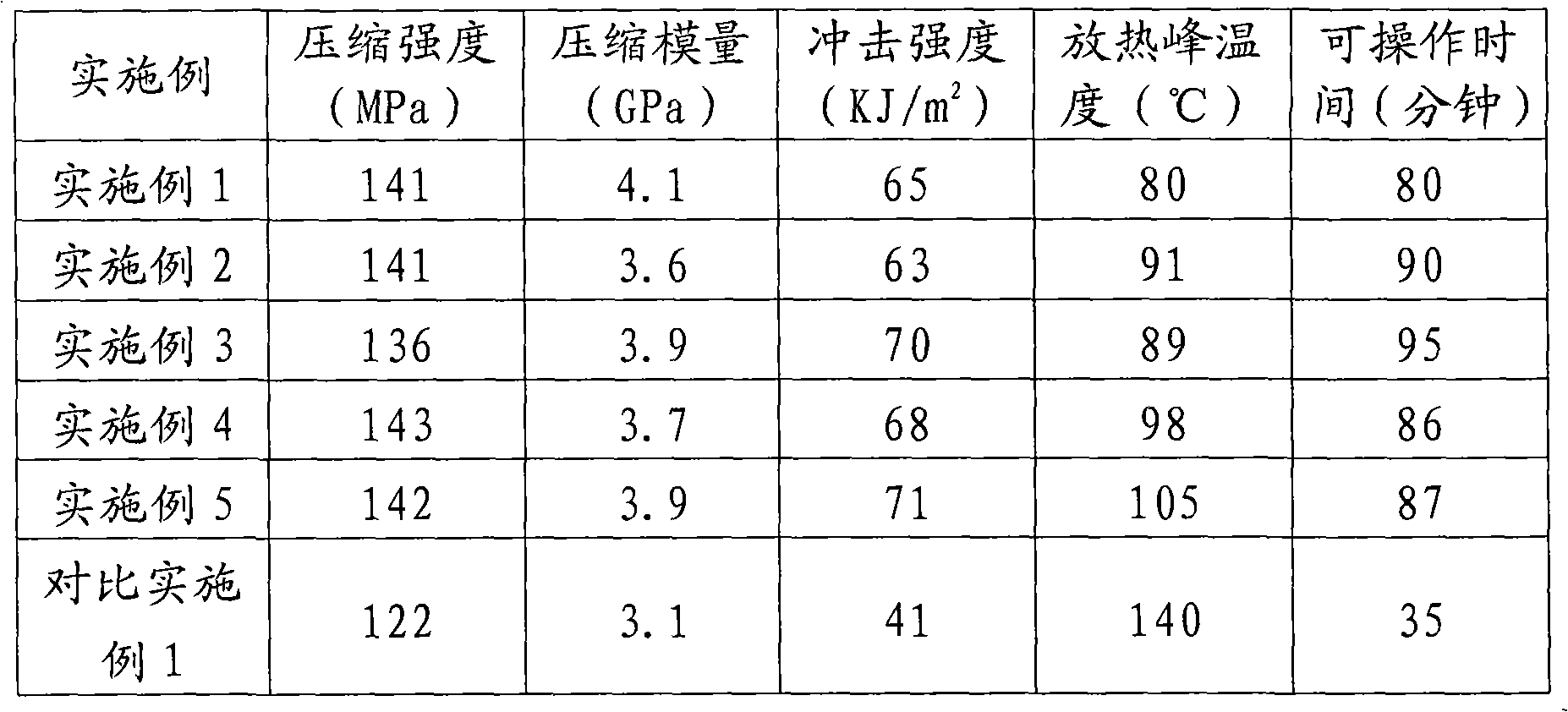

Examples

Embodiment 1

[0035] Accurately weigh the following raw materials, bisphenol A type epoxy resin 10g, bisphenol F type epoxy resin 10g, polyurethane acrylate toughening agent 5g, nonylphenol 2g, fumed silicon 0.1g, BYK-163 dispersant 0.3 g, BYK A-506 defoamer 0.1g, 1,4-butanediol diglycidyl ether 3g, calcium carbonate 69.5g, add the above components into the double planetary power mixing mixer in turn, the rotation speed is 1000 rpm Minutes, under the condition of revolution speed of 15 rev / min, mechanically stirred for 2.5 hours to obtain component A, mixed uniformly to obtain component A of the epoxy resin adhesive, packed and placed for use; 10g of triethylenetetramine, isophor 40 g of ketone diamine, 20 g of low molecular weight polyamide, and 10 g of bis(4-amino-3-methylcyclohexyl)methane were mixed uniformly to obtain a curing agent for epoxy resin adhesive, which was packaged and placed for use.

[0036] When in use, the prepared component A and curing agent are mixed in a weight rati...

Embodiment 2

[0038] Accurately weigh the following raw materials: 54g of bisphenol A epoxy resin, 5g of liquid carboxyl-terminated nitrile rubber (CTBN) toughening agent, 5g of nonylphenol, 0.5g of organic bentonite, 0.3g of BYK-163 dispersant, BYK A-506 defoamer 0.2g, butyl glycidyl ether 5g, silicon micropowder 30g, add the above components into the double planetary power mixing mixer in turn, the rotation speed is 800 rpm, and the revolution speed is 10 rpm Under the condition of mechanical stirring for 2.5 hours to obtain component A, mix evenly to obtain component A of the epoxy resin adhesive, pack and place it for use; 15g of triethylenetetramine, 35g of N-aminoethylpiperazine, and 20g of polyetheramine , 5g of bis(4-amino-3-methylcyclohexyl)methane, mixed uniformly to obtain a curing agent for epoxy resin adhesive, packed and placed for use.

[0039] When in use, the prepared component A and curing agent are mixed in a weight ratio of 100:6.8, and cured for 16 hours under ambient c...

Embodiment 3

[0041]Accurately weigh the following raw materials, bisphenol A type epoxy resin 15g, bisphenol F type epoxy resin 15g, epoxy acrylate toughening agent 8g, nonylphenol 7g, fumed silicon 0.3g, Anti-terra-U Dispersant 0.15g, BYK A-525 antifoaming agent 0.15g, neopentyl glycol diglycidyl ether 3g, mica powder 30g, talcum powder 21.4, add the above-mentioned components in the double planetary power mixing mixer in turn, and the rotation speed is 1000 rev / min, revolution speed is under the condition of 15 rev / min, mechanically stirred for 3 hours to obtain component A, mix uniformly, obtain the A component of epoxy resin adhesive, pack and place for use; Diethylenetriamine 8g, 38g of hydroxyethylpiperazine, 20g of low-molecular-weight polyamide, and 7g of bis(4-aminocyclohexyl)methane were mixed uniformly to obtain a curing agent for epoxy resin adhesive, which was packaged and placed for use.

[0042] When in use, the prepared component A and curing agent are mixed in a weight rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com