Systems and methods for applying a liquid coating material to a substrate

a technology of liquid coating material and substrate, applied in the direction of liquid transferring device, transportation and packaging, packaging, etc., can solve the problems of inaccurate inaccurate calculation of flow rate, and inaccurate use of conventional coating material dispensing system,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

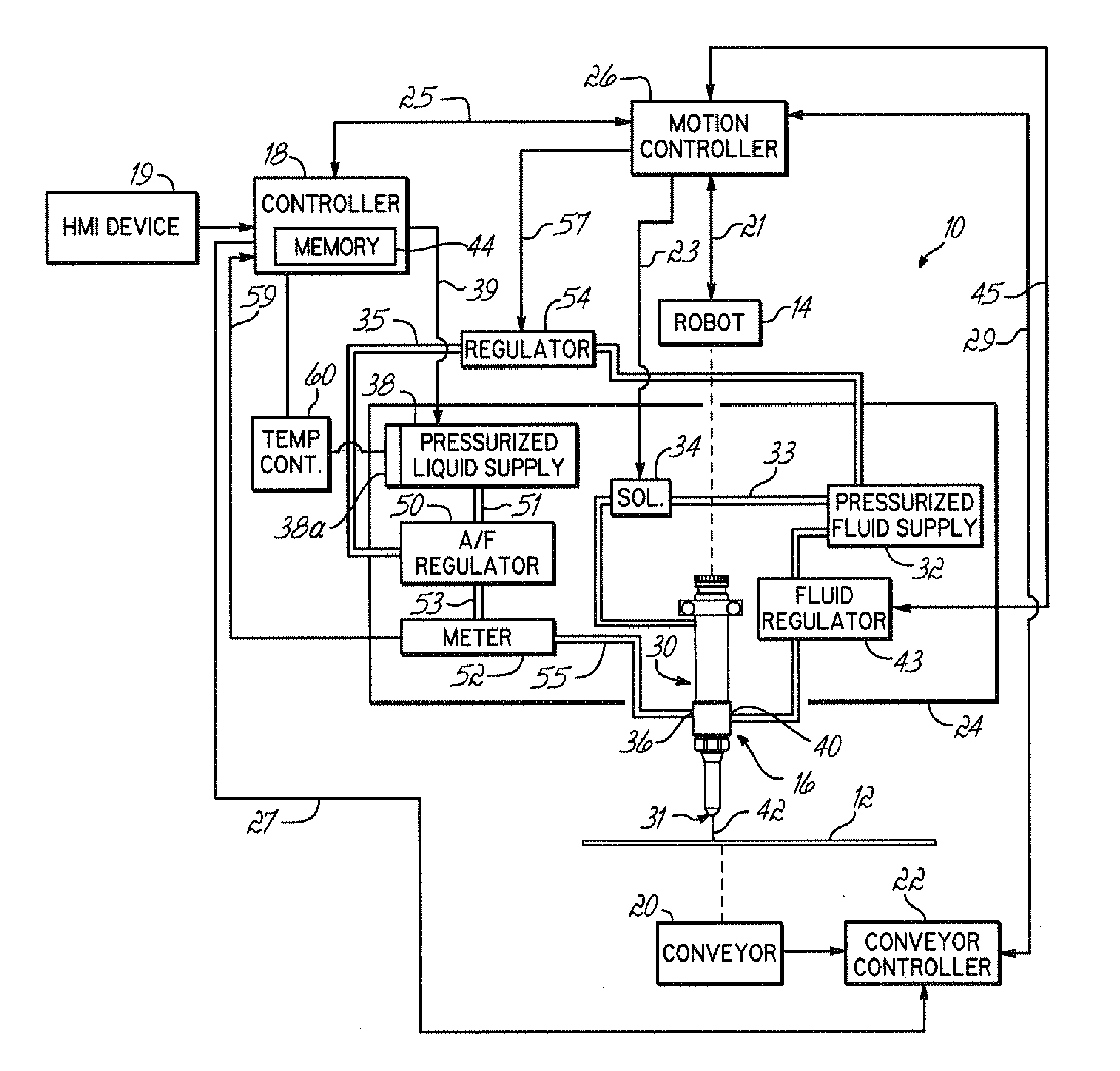

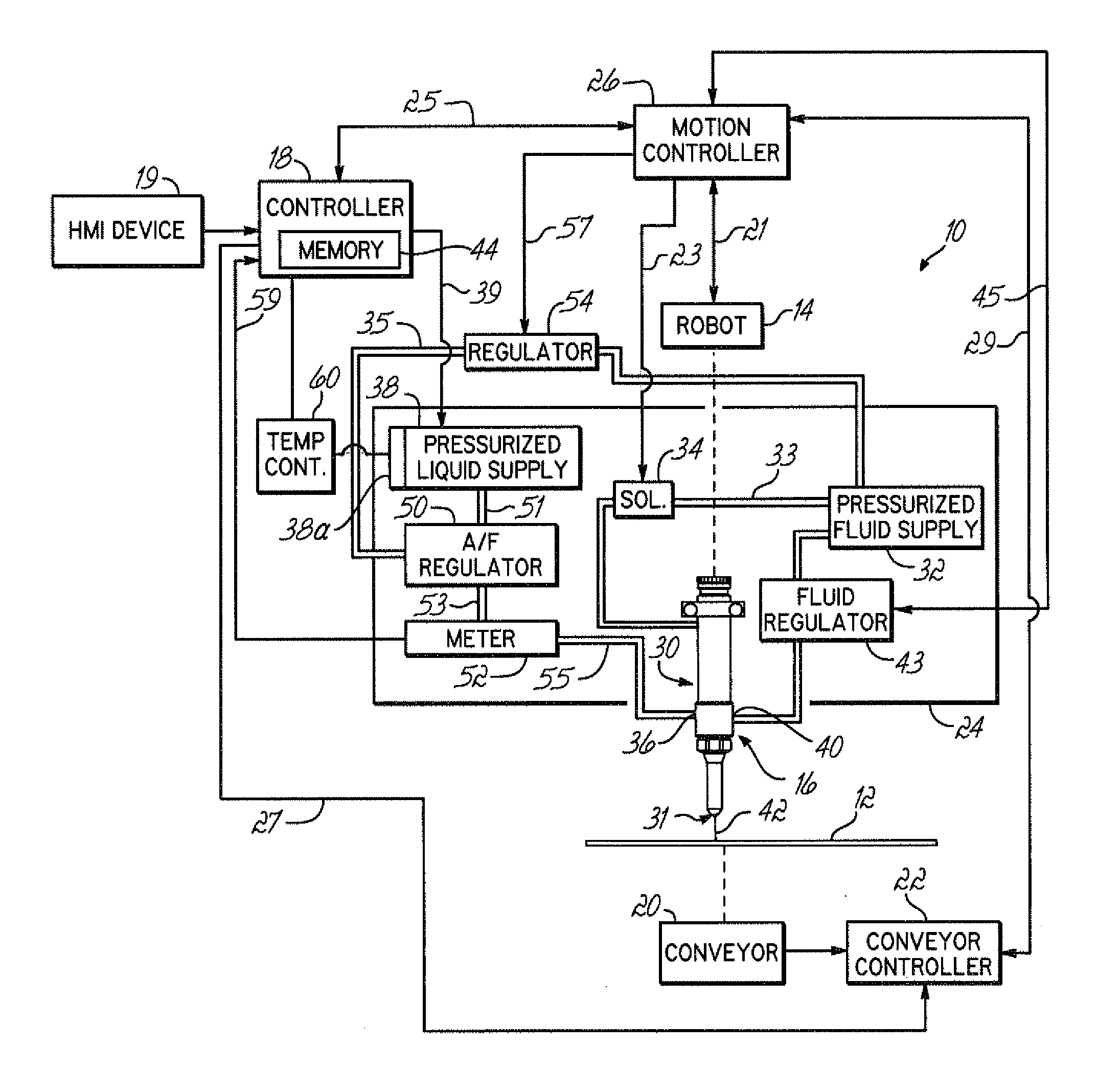

[0012]With reference to the FIGURE, a coating system 10 may be used to apply a liquid coating material, such as a conformal coating material, to a series of substrates, such as the representative substrate 12. Although the operation of a representative coating system 10 will be described herein, those skilled in the art will appreciate that a wide variety of other coating systems may be used to complete the method described below. The coating system 10 may be, for example, a Model SC-105, SC-205, or SC-400 conformal coating applicator commercially available from Asymtek (Carlsbad, Calif.).

[0013]In the representative embodiment, the coating system 10 includes a multi-axis electro-mechanical positioner or robot 14 and a conformal coating applicator 16 coupled with the robot 14. For example, the applicator 16 may be suspended from the robot 14 above the substrates 12. In one embodiment, the robot 14 is adapted to move the applicator 16 in directions defined within an X-Y-Z Cartesian co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| areas | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volumes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com