Nano zirconium phosphate-modified triazine macromolecular charring agent, and preparation method and application thereof

A nano-zirconium phosphate and macromolecular technology is applied in the field of nano-zirconium phosphate-modified triazine macromolecular carbon-forming agent and its preparation, which can solve the problems of difficult dispersion of nano-materials, difficulty in obtaining composite materials, etc., and achieve excellent compactness and thermal stability. The effect of high performance, high yield and excellent carbon-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

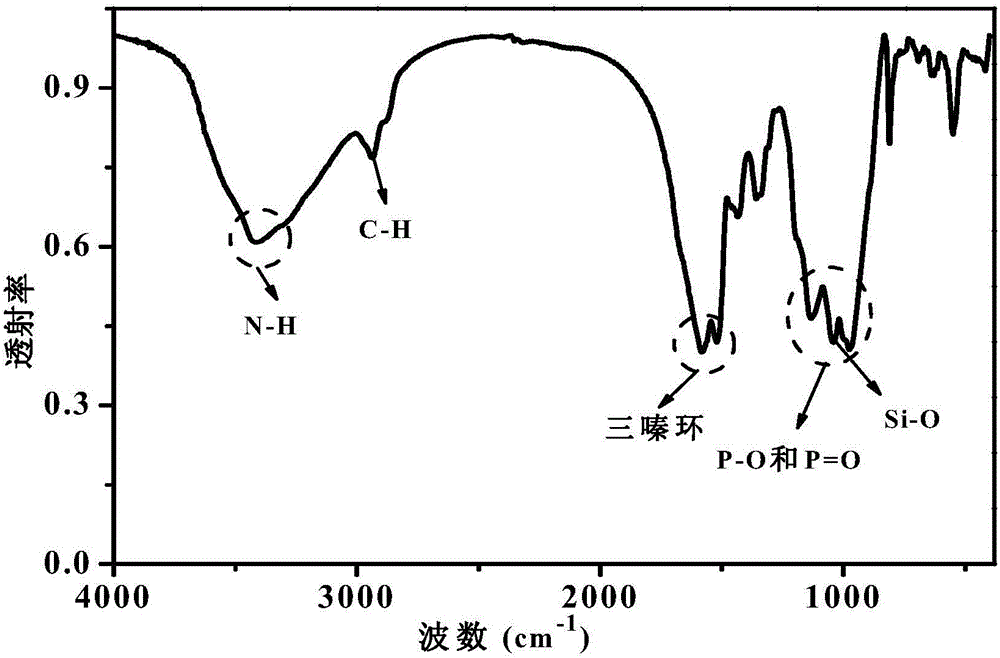

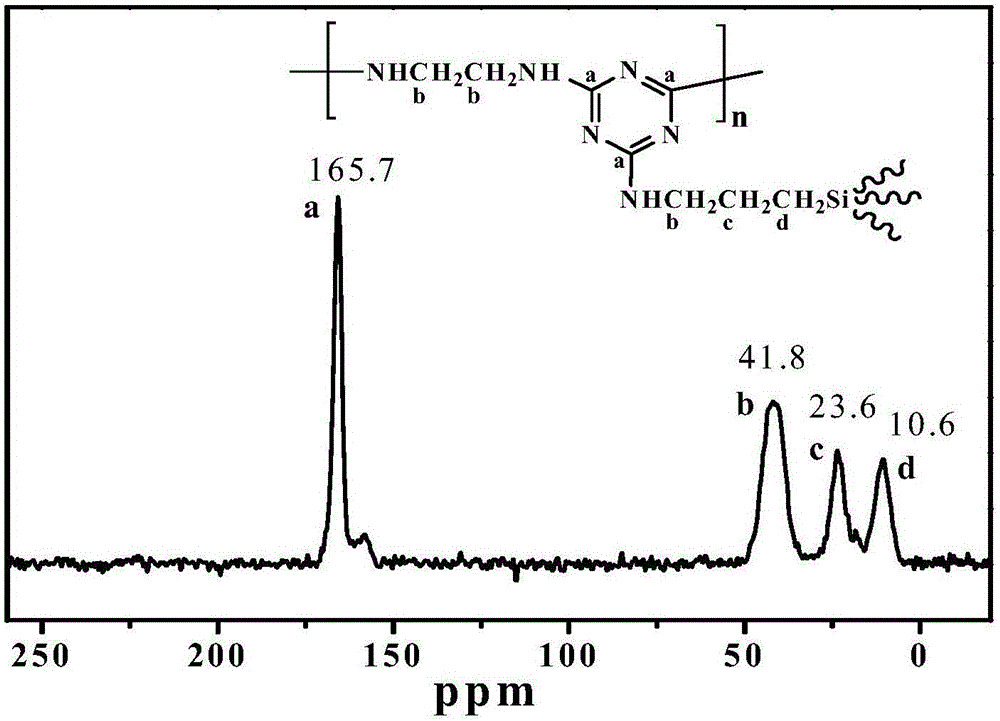

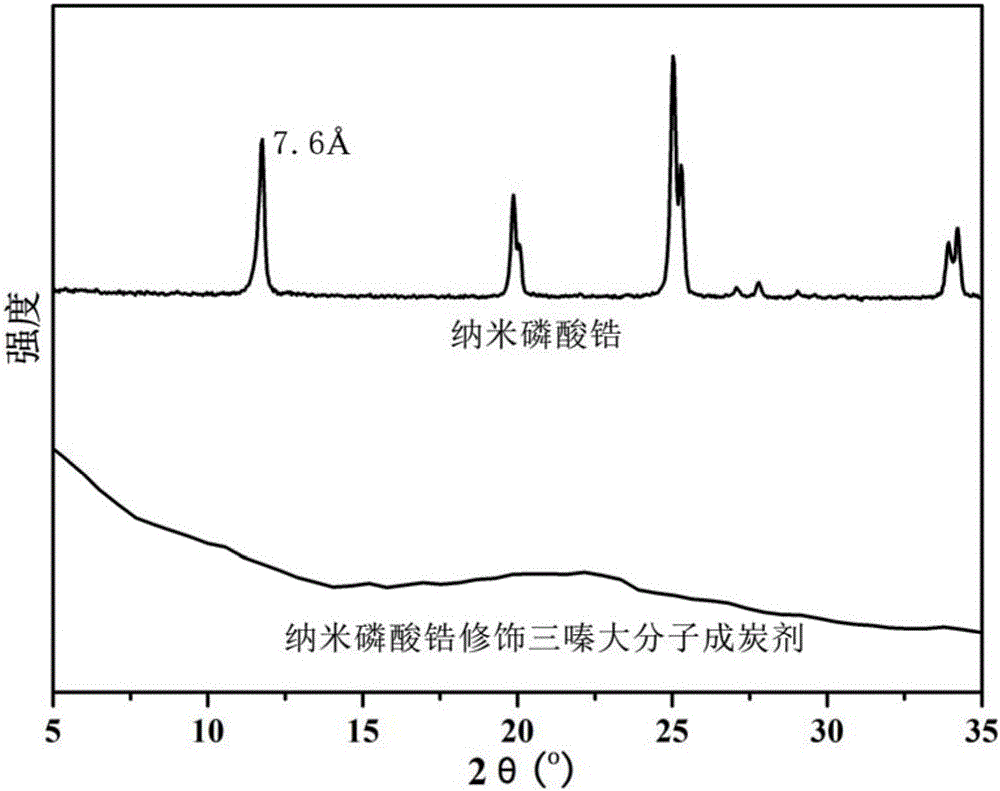

[0046] 1) Silane coupling agent intercalation nano-zirconium phosphate: Add 450mL acetone and 5g (0.018mol) zirconium phosphate (diameter of the sheet is about 100nm) into a 1L four-necked flask at 0-5°C, and stir ultrasonically for 30min; Dissolve 11.95g (0.054mol) of 3‐aminopropyltriethoxysilane in 50mL of acetone, add it dropwise to the flask within 0.5h, continue ultrasonic stirring for 1.5h, then stop ultrasonic and continue stirring for 6h; The mixed solution was concentrated to 200 mL by rotary evaporation for the next reaction.

[0047] 2) Synthesis of intermediate products: at 0-5°C, add 100mL of acetone and 10.14g (0.055mol) of cyanuric chloride into a 500mL four-necked flask, and stir evenly; Add it dropwise in the four-necked flask, and slowly add an aqueous sodium hydroxide solution with a concentration of 20wt% at the same time, and react for 3 hours after the drop; the temperature is raised to 55°C, and 1.66g (0.028mol) of 1,2‐ethylenediamine Dissolve 2.2g (0.0...

Embodiment 2

[0053] The difference between this example and Example 1 is that the amount of zirconium phosphate in step 1) is changed to 7.65 g (0.027 mol), and the amount of acetone is changed to 700 mL. The flame retardant performance test and thermogravimetric analysis results are shown in Table 1.

Embodiment 3

[0055] The difference between this example and Example 1 is that the amount of zirconium phosphate in step 1) is changed to 3.82 g (0.014 mol), and the amount of acetone is changed to 350 mL. The flame retardant performance test and thermogravimetric analysis results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com