Concrete demoulding agent and preparation method thereof

A technology of concrete release agent and emulsifier, which is applied in the field of building materials, can solve the problems of endangering the health of operators, polluting air quality, and easy generation of oil mist, etc., and achieves good demoulding quality, simple process, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

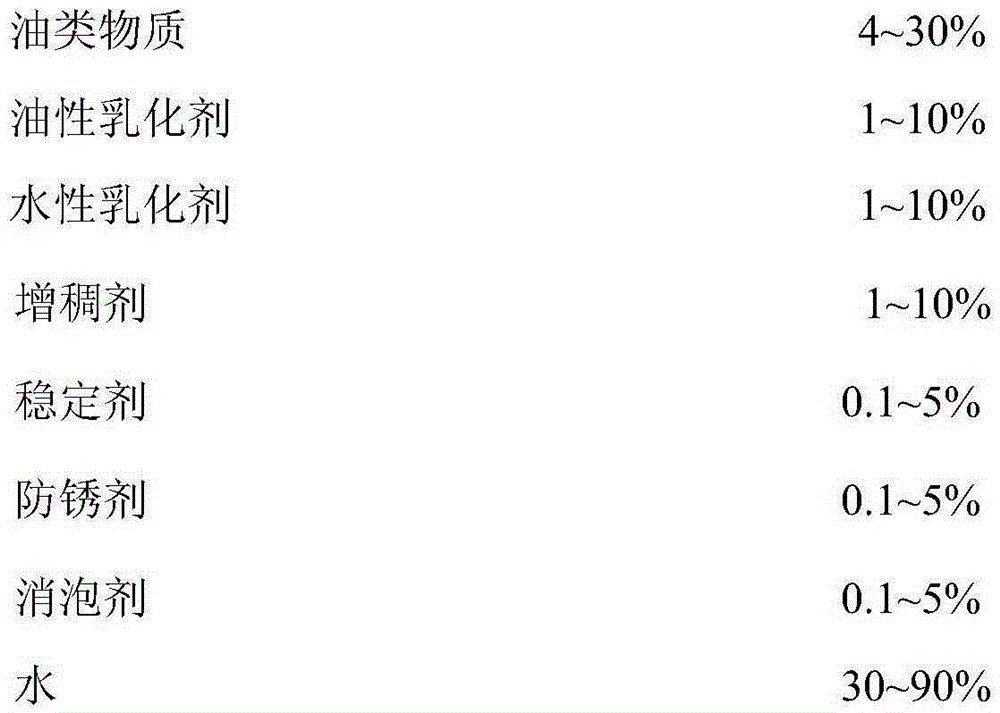

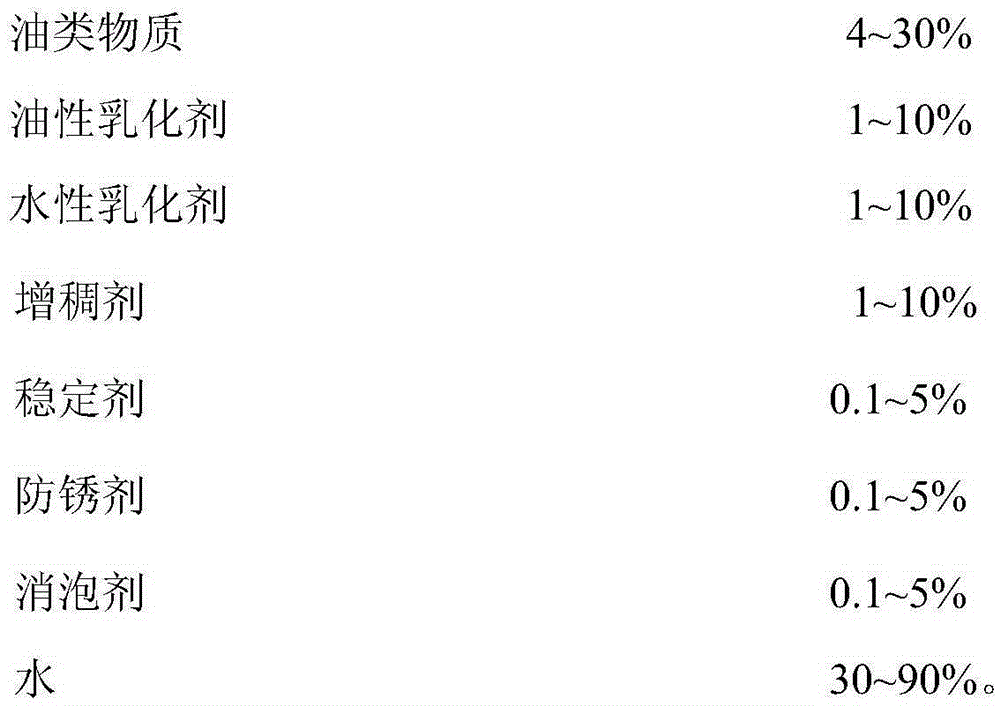

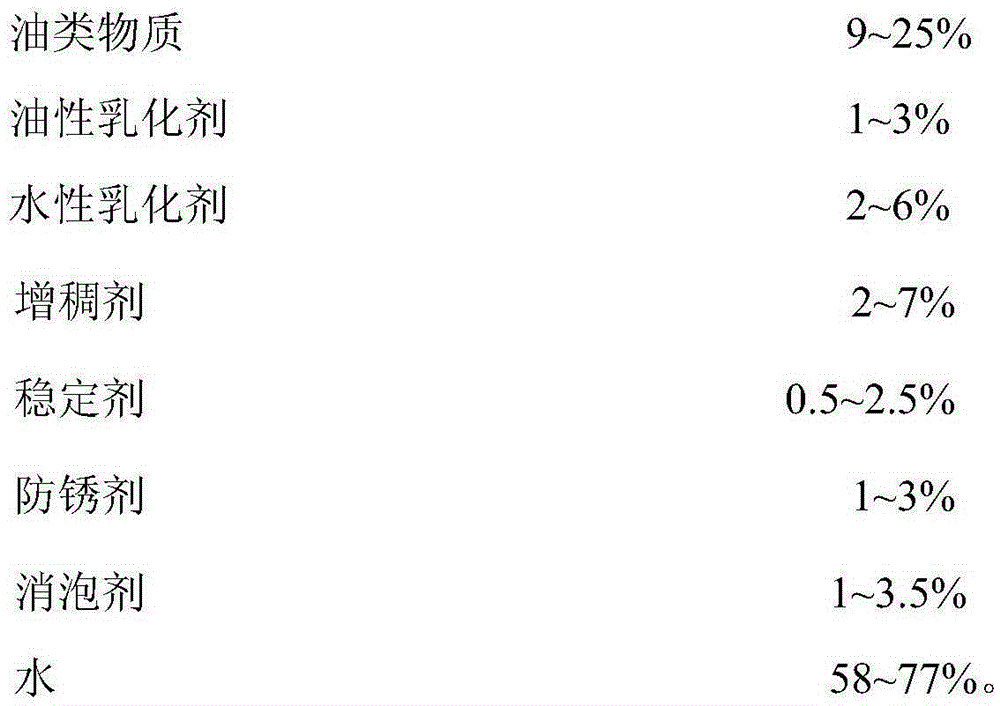

Method used

Image

Examples

Embodiment 1

[0028] In parts by weight, put 20 parts of trimethylolpropane trioleate and 5 parts of isopropyl oleate into the reactor, start the stirring device, then add 1 part of Span80 and 2 parts of nonylphenol polyoxyethylene Ether (NP-10), mixed and stirred for 30min. Then add 0.5 parts of polyvinyl alcohol, 1 part of triethanolamine, 0.5 parts of silicone defoamer, 68 parts of water, and stir for 60 minutes. Finally, slowly add 2 parts of polyacrylate thickener (HT-9) for 20 minutes, and stir for 40 minutes to become the concrete release agent.

Embodiment 2

[0030] In parts by weight, put 12 parts of trimethylolpropane trioleate and 5 parts of liquid paraffin into the reaction kettle, start the stirring device, then add 1 part of Span80, 1 part of fatty alcohol block polyether MOA-3 And 2 parts of alkylphenol polyoxyethylene ether SOPE-10, mixed and stirred for 30min. Then add 1 part of polyvinyl alcohol, 1.5 parts of sodium borate, 3 parts of modified polyether defoamer HY-2045, 70 parts of water, and stir for 60 minutes. Finally, slowly add 3.5 parts of polyacrylic acid thickener HY-303 for 20 minutes, and stir for 40 minutes to become the concrete release agent.

Embodiment 3

[0032] In parts by weight, put 10 parts of trimethylolpropane trioleate, 5 parts of isopropyl oleate and 5 parts of naphthenic oil into the reaction kettle, start the stirring device, and then add 3 parts of fatty alcohol block polymer Ether MOA-4 and 6 parts of nonylphenol polyoxyethylene ether NP-10 were mixed and stirred for 30 minutes. Then add 1.5 parts of polyvinyl alcohol, 1 part of xanthan gum, 1.5 parts of sodium borate, 1.5 parts of triethanolamine, 2 parts of modified polyether defoamer HY-2045, 58.5 parts of water, and stir for 60 minutes. Finally, slowly add 5 parts of polyacrylate thickener HT-9 for 20 minutes, and stir for 40 minutes to become the concrete release agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com