Method for removing sulfur from waste lead-acid storage battery gypsum mud by using magnesium chloride

A waste lead-acid battery and magnesium chloride technology, which is applied in the field of desulfurization from waste lead-acid battery paste and waste lead-acid battery treatment, can solve the problems of large production scale, high investment cost, and long process flow, and achieve production equipment Low requirements, low production cost, good desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

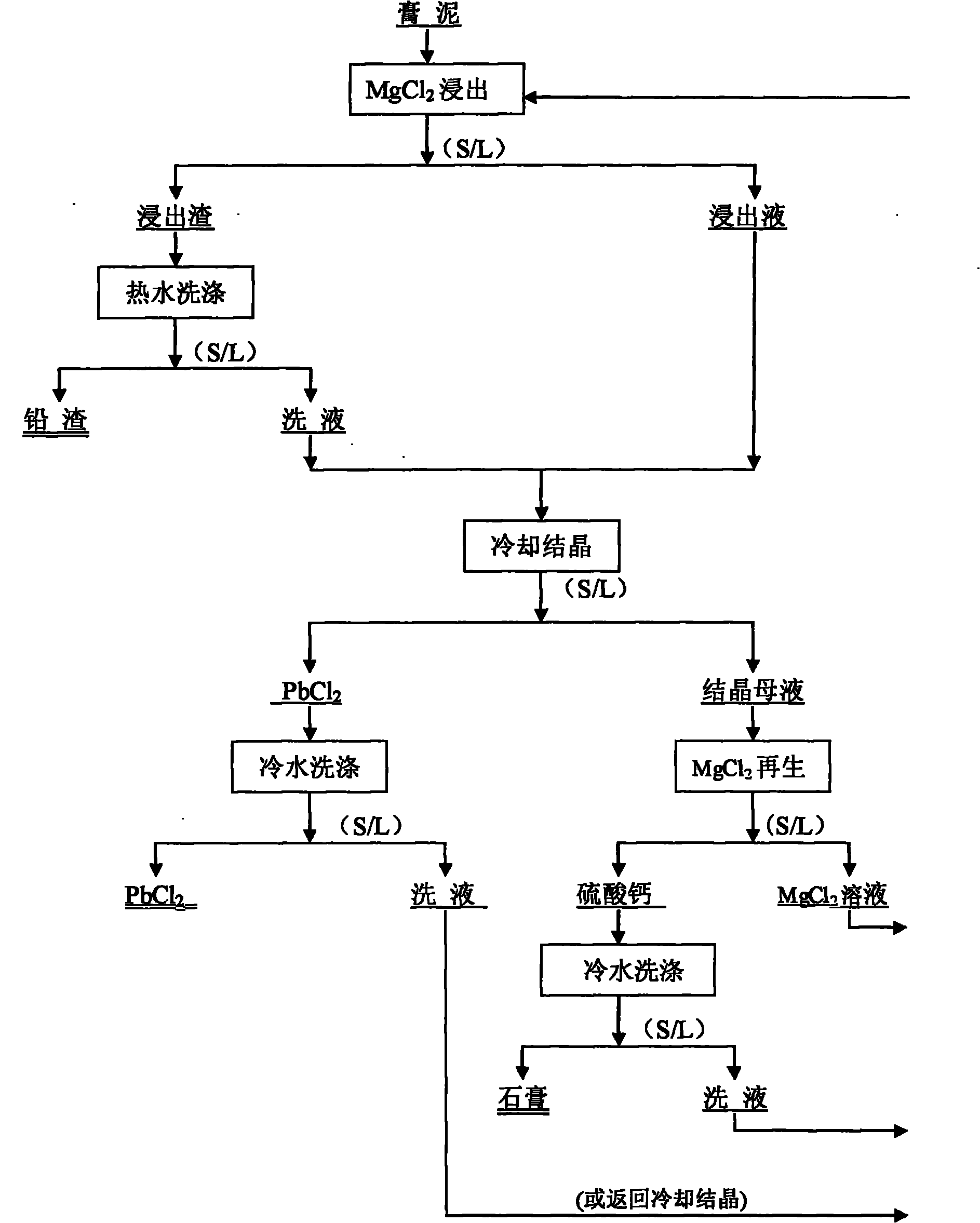

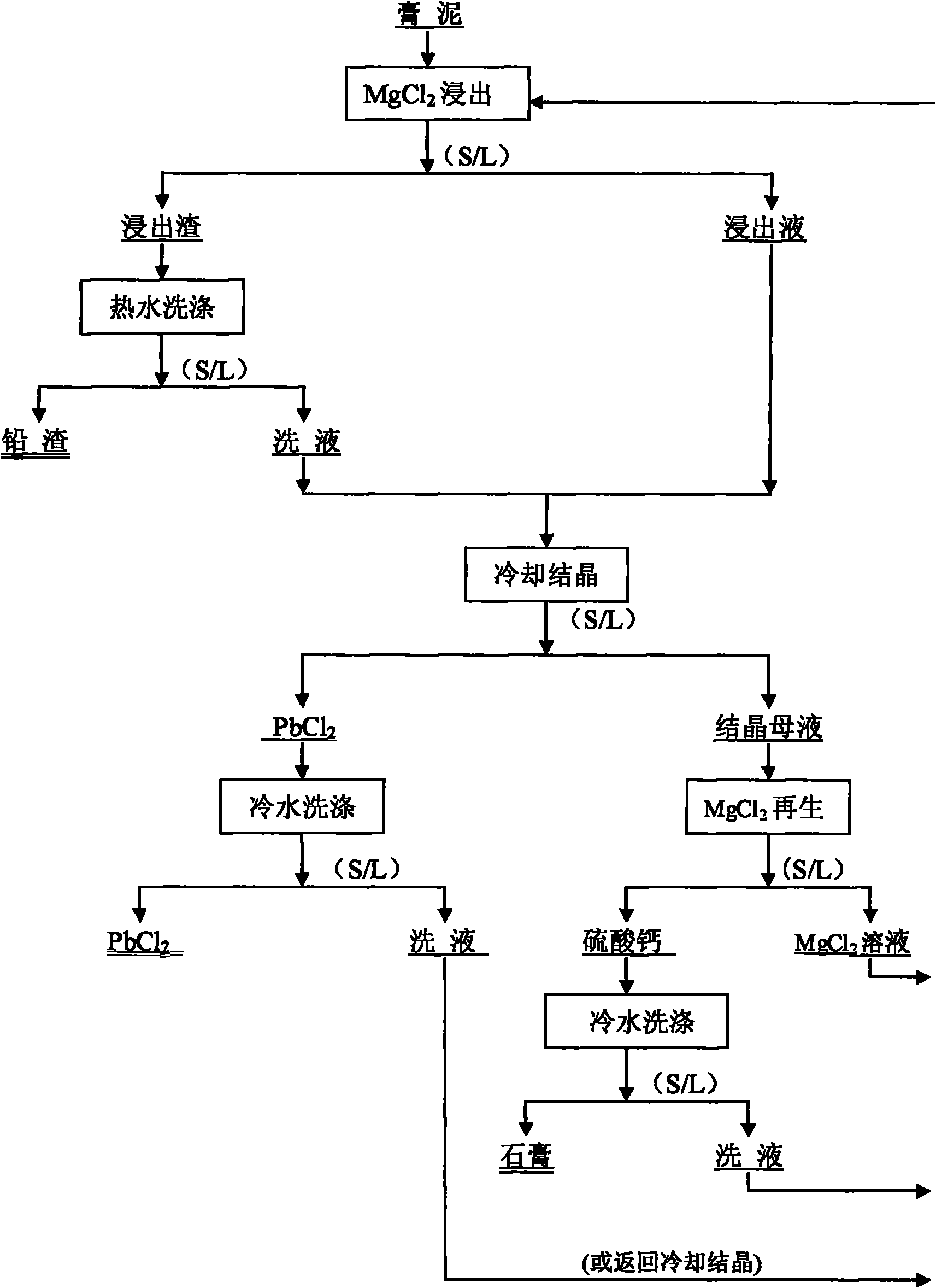

[0035]The paste mud obtained by decomposing the waste lead storage battery after pouring acid is put into the magnesium chloride solution for stirring and leaching. The technical conditions for desulfurization and leaching of paste mud are: magnesium chloride concentration: 3.5mol / L, liquid-solid ratio 3:1, leaching temperature: 90°C, and reaction time 120min. After the reaction is completed, liquid-solid separation is carried out, the leaching slag is washed with hot water, and the obtained lead slag is smelted at low temperature to produce crude lead; the washing liquid and the leaching liquid are cooled and crystallized together, and solid lead chloride and crystallization mother liquor are obtained after solid-liquid separation. After the lead chloride is washed with cold water, it is smelted at low temperature to produce crude lead. The washing liquid is returned to the desulfurization and leaching process of paste mud, or to the cooling and crystallization process of lead...

Embodiment 2

[0042] The paste mud obtained by decomposing the waste lead storage battery after pouring acid is put into the magnesium chloride solution for stirring and leaching. The technical conditions for desulfurization and leaching of paste mud are: magnesium chloride concentration: 4.5mol / L, liquid-solid ratio 4:1, leaching temperature: 95°C, reaction time 120min, after the reaction is completed, liquid-solid separation is carried out, and the leaching residue is washed with hot water. The obtained lead slag is smelted at low temperature to produce crude lead; the lotion and leaching solution are cooled and crystallized together, and solid lead chloride and crystallization mother liquor are obtained after solid-liquid separation. Paste mud desulfurization leaching process, or return to the lead chloride cooling crystallization process; the crystallization mother liquor is added with calcium chloride from the leaching process of lead chloride low-temperature smelting slag to regenerate...

Embodiment 3

[0049] The paste mud obtained by decomposing the waste lead storage battery after pouring acid is put into the magnesium chloride solution for stirring and leaching. The technical conditions for desulfurization and leaching of paste mud are: magnesium chloride concentration: 5.5mol / L, liquid-solid ratio 4:1, leaching temperature: 95°C, reaction time 90min, after the reaction is completed, liquid-solid separation is carried out, and the leaching residue is washed with hot water. The obtained lead slag is smelted at low temperature to produce crude lead; the lotion and leaching solution are cooled and crystallized together, and solid lead chloride and crystallization mother liquor are obtained after solid-liquid separation. Paste mud desulfurization leaching process, or return to the lead chloride cooling crystallization process; crystallization mother liquor is added calcium chloride to regenerate the desulfurizer, and at the same time obtain by-product calcium sulfate (gypsum),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| stone rate | aaaaa | aaaaa |

| stone rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com