Method for preparing galvanic deposit calcium phosphorus mineralized layer superfine fibre bone material

An ultra-fine fiber, electrodeposition technology, applied in medical science, prosthesis, etc., can solve the problems of unsuitable bioactive component loading, composite fiber degradation, long time, etc., achieve short preparation time, mild conditions, good phase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

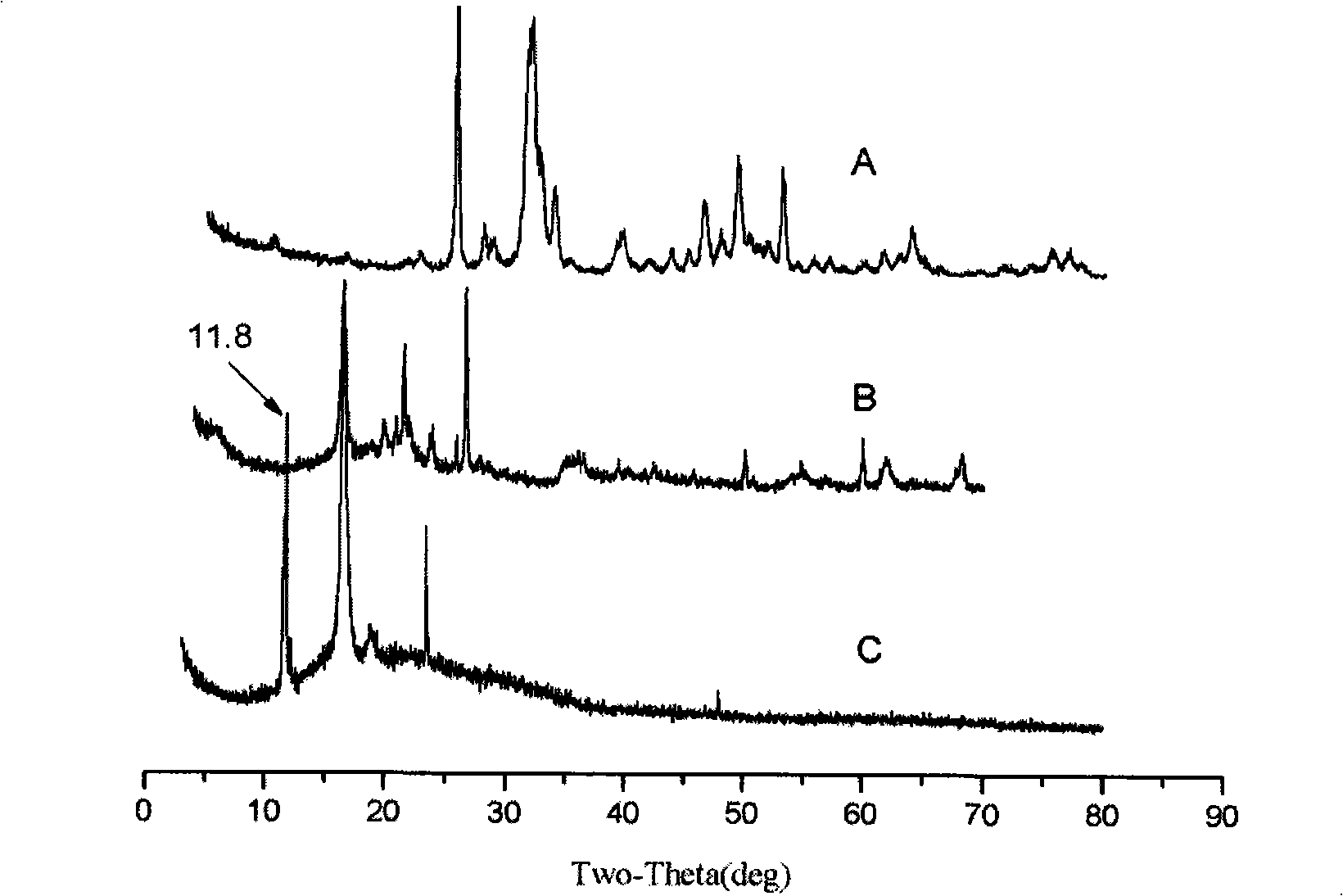

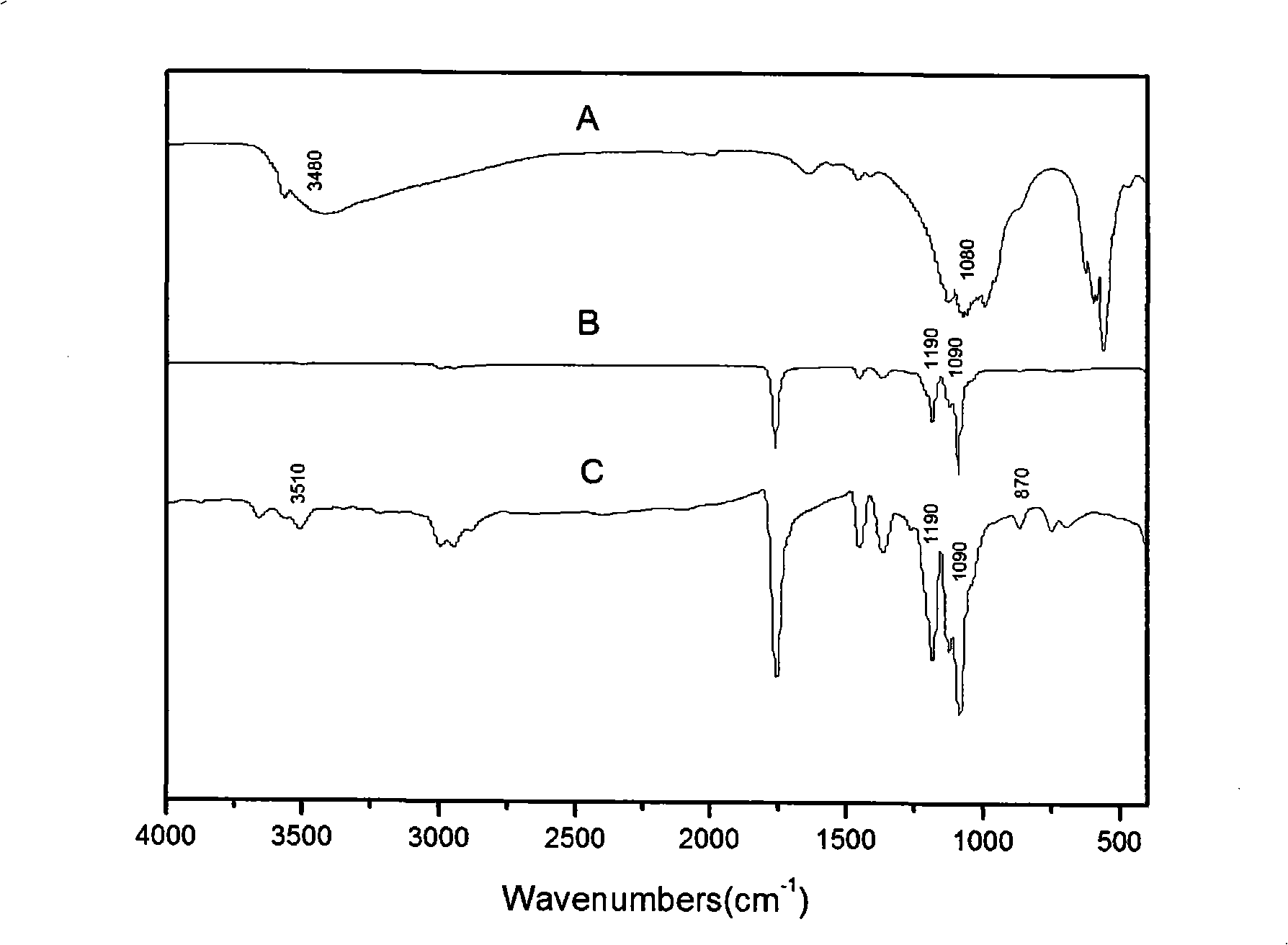

[0033] (1) Using chloroform / acetone with a volume ratio of 3:1 as solvent, prepare 6% (w / v) PLLA (molecular weight: 130,000) electrospinning solution;

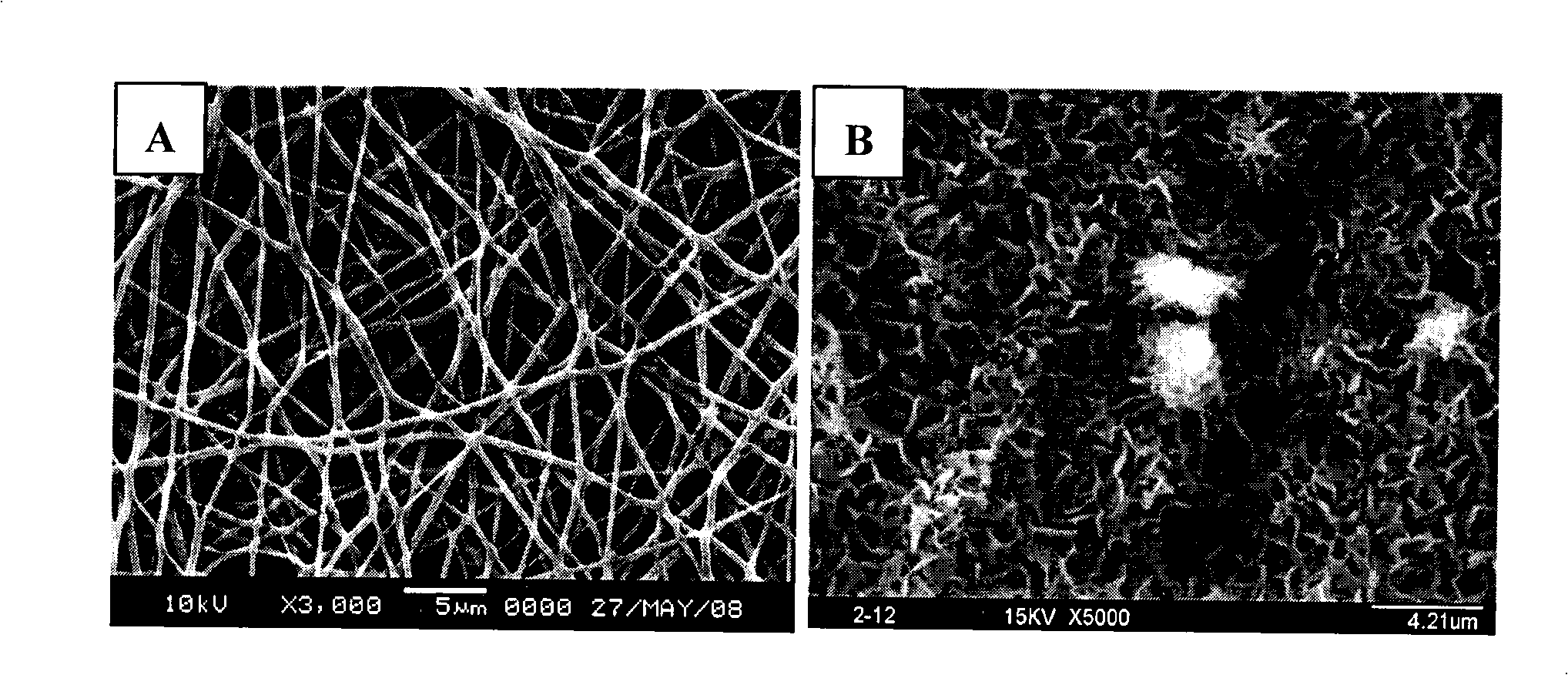

[0034] (2) A 2cm×2cm platinum electrode was selected, and the surface was polished and cleaned as an electrospinning collection device, and PLLA ultrafine fibers were prepared on the surface of the electrode by single-nozzle electrospinning technology. A 21G injection needle (inner diameter 0.51mm) is used as the spinneret, a high-voltage electrostatic generator provides DC high voltage, and a micro-injection pump delivers the electrospinning solution; the electrospinning parameters are: the voltage is 16.0KV, the receiving distance is 15.0cm, and the liquid supply rate is 1.2ml / h, after 30 minutes, the surface of the electrode is covered with a PLLA fiber membrane with a thickness of about 0.1mm, and the other side of the electrode is replaced with a PLLA fiber membrane of the same thickness;

[0035] (3) Prepare 100ml electr...

Embodiment 2

[0039] (1) The material used is type I collagen (molecular weight 0.8-1.0×10) purchased from Sichuan Mingrang Biotechnology Co., Ltd. 5 ), using hexafluoroisopropanol as a solvent to prepare an electrospinning solution with a concentration of 8% (w / v);

[0040] (2) Receive electrospun collagen fibers on both sides of platinum electrodes. The electrospinning parameters are: the voltage is 15KV, the receiving distance is 10cm, the liquid supply rate is 0.8ml / h, and the receiving time of the single-sided electrode is 30min. After the collagen fibers are collected on both sides of the electrode, place it in a vacuum drying oven at room temperature for 12 hours to remove residual solvent;

[0041] The rest is the same as in Example 1, and the mineralized collagen porous bone material is prepared.

Embodiment 3

[0043] The same as in Example 1, the difference is that the coaxial electrospinning technology is used to prepare skin-core electrospun ultrafine fibers on both sides of the platinum electrode. The coaxial co-spinning device in this embodiment uses a 21G injection needle as the inner needle (inner diameter 0.51 mm, outer diameter 0.8 mm), and the inner diameter of the outer spray needle is 1.6 mm. The inner injection needle is indented about 5mm inward. The cortex material was made of 10% (w / v) PLLA electrospinning solution, the core material was made of 3% PEO added with recombinant human bone morphogenetic protein-2 (rhBMP-2) (80-100 μg / mL electrospinning solution), and chloroform and sterile saline as solvents to prepare skin and core electrospinning solution. During coaxial co-spinning, the output voltage is controlled to be 18KV, the supply speeds of the skin and core layer solutions are 3ml / h and 0.4ml / h respectively, and the receiving distance is 12cm.

[0044] The re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com