Polypropylene and blends particles thereof physical gas foaming preparation method

A technology of gas foaming and polypropylene, applied in the field of physical gas foaming of high polymer particles, can solve the problems of complex production process, low production efficiency, high production cost, etc., to reduce production cost, improve production efficiency, and reduce pressure holding the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

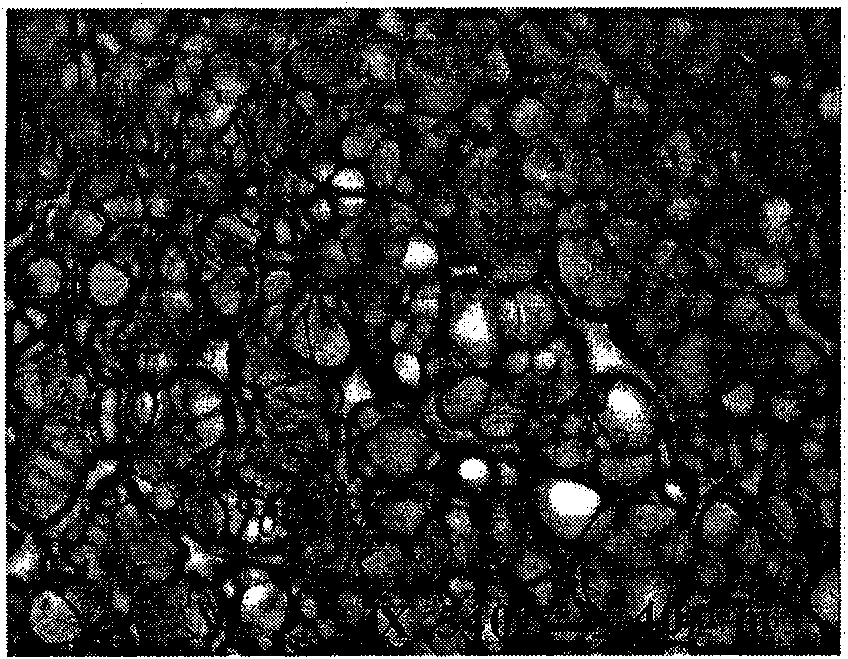

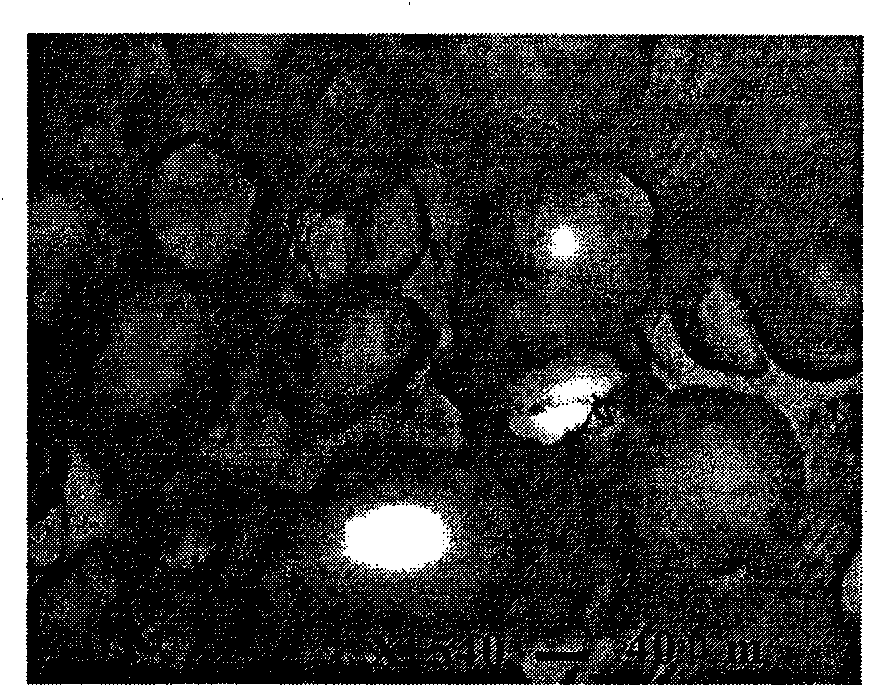

[0045] Place the random copolymerized polypropylene particles in a high-pressure mold with good airtight performance to ensure that the total volume of the particles does not exceed 1 / 25 of the mold volume, so that the particles have enough space for foaming. Filled with high pressure N at a temperature of 135°C 2 , the pressure is controlled at 20MPa, kept at constant temperature and pressure for 19min, and the pressure is released to normal pressure at a speed of 20MPa / s. Then the expanded particles are taken out from the mould, cooled to obtain the expanded particles, and the expanded density of the analyzed and tested expanded particles is 0.30g / cm 3 , with an average pore size of 30 μm.

Embodiment 2

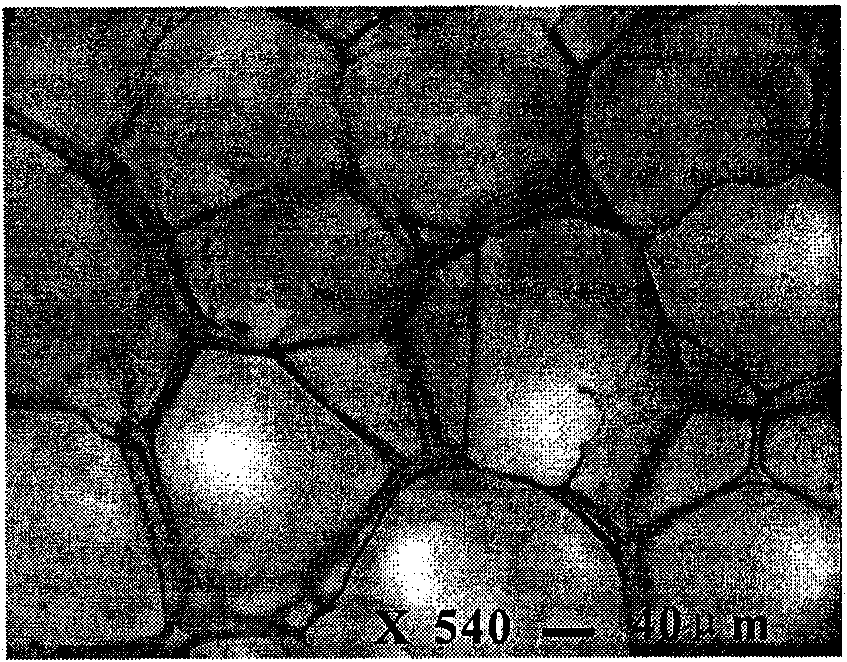

[0047] The block copolymerized polypropylene particles are placed in a high-pressure mold with good airtight performance to ensure that the total volume of the particles does not exceed 1 / 25 of the mold volume, so that the particles have enough space for foaming. Filled with high pressure N at a temperature of 175°C 2 , the pressure is controlled at 20MPa, kept at constant temperature and pressure for 10min, and the pressure is released to normal pressure at a speed of 5MPa / s. Then the expanded particles are taken out from the mould, cooled to obtain the expanded particles, and the expanded density of the analyzed and tested expanded particles is 0.47g / cm 3 , with an average pore size of 270 μm.

Embodiment 3

[0049] Place the homopolymerized polypropylene particles in a high-pressure mold with good airtight performance to ensure that the total volume of the particles does not exceed 1 / 25 of the mold volume, so that the particles have enough space for foaming. Filled with high pressure N at a temperature of 168°C 2 , the pressure is controlled at 20MPa, kept at constant temperature and pressure for 5 minutes, and the pressure is released to normal pressure at a speed of 10MPa / s. Then the expanded particles are taken out from the mould, cooled to obtain the expanded particles, and the expanded density of the analyzed and tested expanded particles is 0.047g / cm 3 , with an average pore size of 190 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Foam density | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com