Method for preparing foam concrete

A foamed concrete and foam technology, applied in the field of foamed concrete preparation, can solve the problems of high cost, poor comprehensive performance of products, low thermal conductivity, etc., and achieve the effects of increasing foaming multiples and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

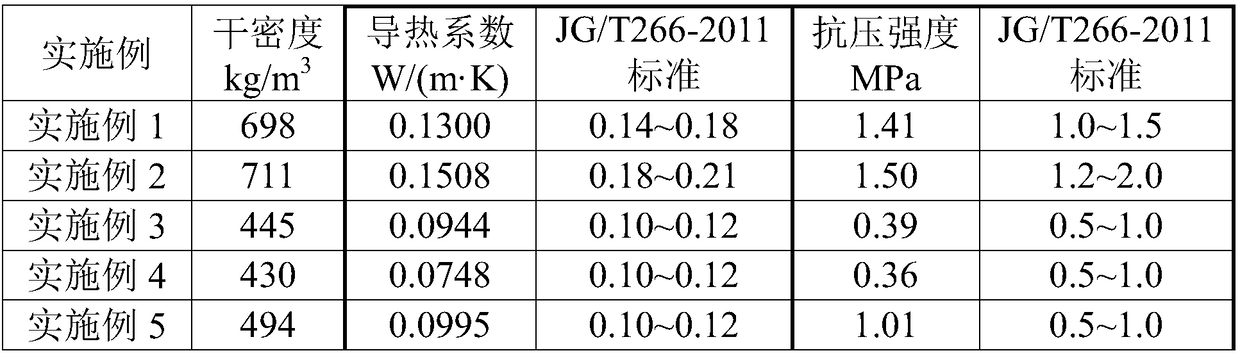

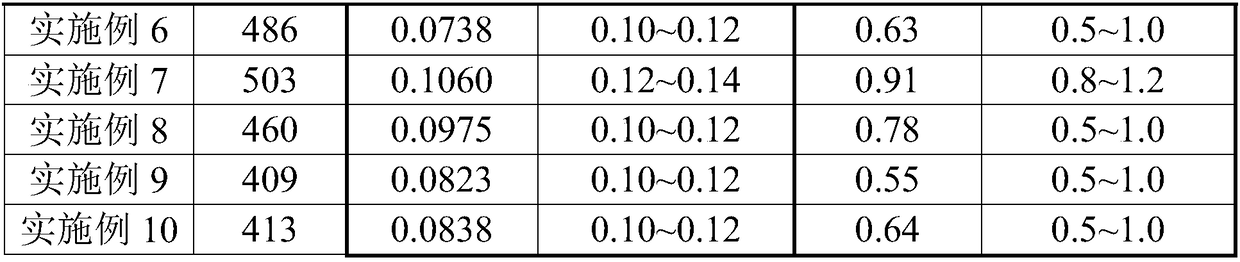

Examples

preparation example Construction

[0028] A kind of preparation method of foamed concrete of the present invention, step is as follows:

[0029] A. Preparation of foaming agent solution: Weigh SDS and APFA with an electronic balance at a mass ratio of 4:6 to obtain a composite foaming agent, and then prepare a foaming agent solution with water at a mass ratio of 1:100.

[0030] B. Prefabricated foam: firstly, open the valve of the air compressor, open the air valve after the pressure reaches 0.5MPa, and control the pressure at about 0.5MPa. Wrap two layers of cotton cloth at the end of the foam pipe, and collect the foam with smaller pores after passing through the cotton cloth into a container.

[0031] C. Preparation of cement foam slurry: take by weight 76 parts of sulphoaluminate cement, 4 parts of Portland cement, 20 parts of fly ash (first-class ultra-fine fly ash, fineness greater than 200 mesh), 1.25 parts coagulant (Al 2 (SO 4 ) 3 , CaCl 2 , triethanolamine or sodium carbonate), 3.5 parts of water...

Embodiment 1

[0036] Weigh 76 parts of quick-hardening sulphoaluminate cement, 4 parts of ordinary Portland cement, 20 parts of fly ash, coagulant Al 2 (SO 4 ) 3 1.25 parts, 0.35 parts of water reducer polycarboxylic acid, 0.4 parts of polypropylene fiber, 0.025 parts of foam stabilizer hydroxypropyl methylcellulose ether and 3.5 parts of admixture sodium methyl silicate and uniformly mixed to obtain a mixture, and then to Add 50 parts of water at a temperature of 22.5°C to the mixture and stir once for 120s, then add 2250ml of foam and stir for a second time for 30s to form cement foam, then cast the mold, demould after natural curing for 24 hours, and wait until a certain age Finally, the dry density, compressive strength and thermal conductivity of the foamed concrete were tested.

Embodiment 2

[0038] Weigh 76 parts of rapid-hardening sulphoaluminate cement, 4 parts of ordinary Portland cement, 20 parts of fly ash, coagulant CaCl 2 1.25 parts, 0.35 parts of water-reducing agent melamine, 0.4 part of alkali-resistant glass fiber, 0.025 parts of foam stabilizer gum arabic powder and 3.5 parts of admixture calcium stearate and uniformly mix to obtain a mixture, then add the mixture at a temperature of Mix 50 parts of water at 30°C for 120s once, then add 2250ml of foam and stir again for 30s to form a cement foam slurry, then cast the mold, remove the mold after 24 hours of natural curing, and test the dry density of the foam concrete after a certain age , thermal conductivity and compressive strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com