Sound absorption and thermal insulation polyolefin foamed sheet and preparation method thereof

A polyolefin foaming and foaming sheet technology, which is applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as poor thermal insulation performance, low thermal conductivity, and poor creep recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

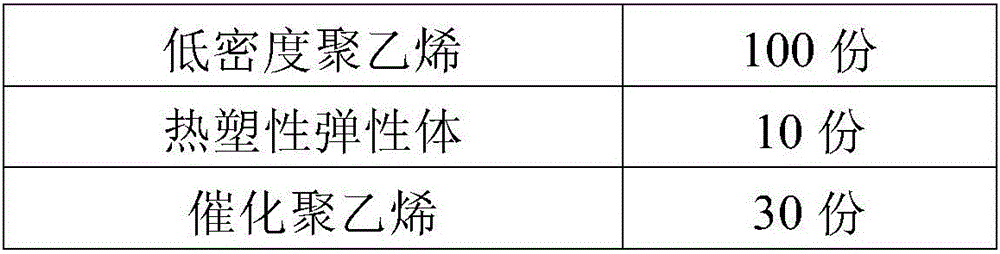

[0046] Sound-absorbing and heat-insulating polyolefin foamed sheet 1 component and weight ratio:

[0047] Low-density polyethylene

100 servings

20 servings

40 servings

Catalyzed Polyethylene

20 servings

Ethylene-vinyl acetate copolymer

20 servings

Nitrile rubber

10 servings

10 servings

Sensitizer

1 serving

0.4 copies

1 serving

Rheological agent

0.4 copies

0.4 copies

Packing A

2 servings

Packing B

2 servings

[0048] The melt index of low-density polyethylene is 0.3g / 10min, the melt index of ethylene-vinyl acetate copolymer is 1.0g / 10min, the melt index of catalytic polyethylene resin is 0.3g / 10min, and the melt index of polypropylene resin is 1.0 g / 10min, the thermoplastic elastomer is a polymer whose hard segment is polypropylene and soft segment is EPDM rubber, the blowing agent is azodicarbonamide, and the cell regulator is stearic acid and...

Embodiment 2

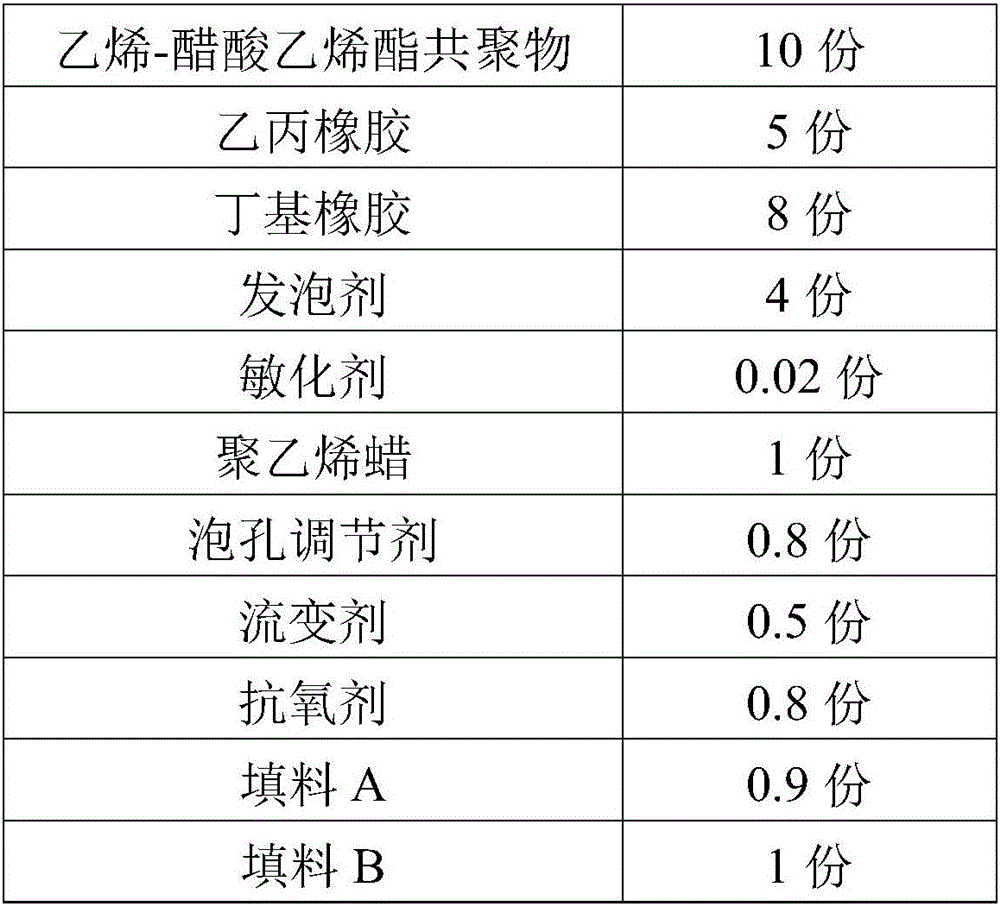

[0056] Sound-absorbing and heat-insulating polyolefin foamed sheet 2 components and weight ratio:

[0057]

[0058]

[0059] The melt index of low density polyethylene is 1.2g / 10min, the melt index of ethylene-vinyl acetate copolymer is 1.5g / 10min, the melt index of catalytic polyethylene resin is 0.8g / 10min, and the melt index of polypropylene resin is 4.0 g / 10min, the thermoplastic elastomer is a polymer whose hard segment is polypropylene, soft segment is ethylene propylene diene rubber, vulcanizing agent, the blowing agent is barium azodicarboxylate, and the cell regulator is trimer Glycerol monostearate and stearic acid monoglyceride, filler A is graphite and carbon black, particle size is 200nm, filler B is silica and titanium dioxide, particle size is 400nm, sensitizer is stearate, oxidation Zinc, the dosage ratio is 5:95.

[0060] Preparation method of sound-absorbing and heat-insulating polyolefin foamed sheet 2:

[0061] 1) Add 50 parts of low-density polyethylene resin i...

Embodiment 3

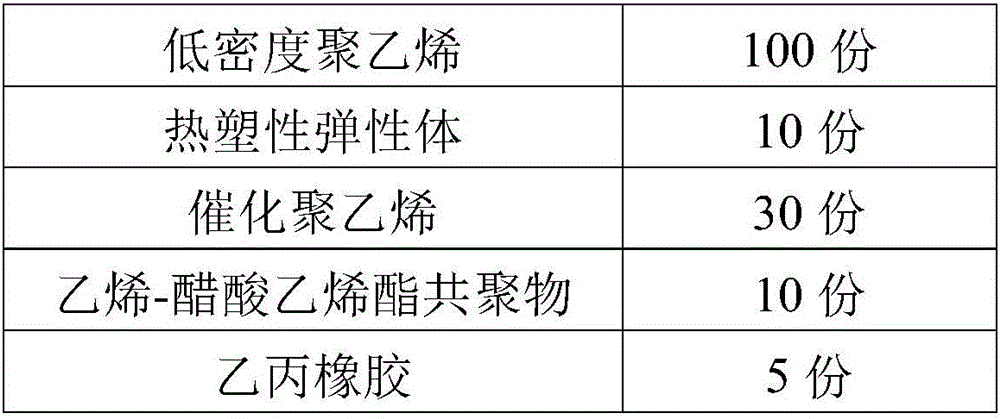

[0067] Sound-absorbing and heat-insulating polyolefin foam sheet 3 components and weight ratio:

[0068] Low-density polyethylene

100 servings

Thermoplastic elastomer

30 servings

50 servings

Catalyzed Polyethylene

30 servings

Ethylene-vinyl acetate copolymer

40 servings

20 servings

Sensitizer

3 copies

8 servings

Cell regulator

7 servings

Rheological agent

8 servings

9 servings

Packing A

7 servings

Packing B

7 servings

[0069] The melt index of low-density polyethylene is 3.0g / 10min, the melt index of ethylene-vinyl acetate copolymer is 8g / 10min, the melt index of catalytic polyethylene resin is 5g / 10min, and the melt index of polypropylene resin is 14g / 10min. , The thermoplastic elastomer is a polymer whose hard segment is polypropylene, soft segment is nitrile rubber, and vulcanizing agent. The blowing agent is azobisisobutyronitrile, and the cell regulator is triglycerin monostear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Financial index | aaaaa | aaaaa |

| Financial index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com