Crosslinking type polyvinyl chloride/thermoplastic polyurethane light foaming material and preparation method thereof

A thermoplastic polyurethane and polyvinyl chloride technology, which is applied in the field of cross-linking technology to prepare polyvinyl chloride/thermoplastic polyurethane foam, and cross-linked polyvinyl chloride lightweight materials, can solve the problem of poor impact resistance of hard products, decreased material performance, The plasticizer is easy to migrate and other problems, to achieve the effect of good dimensional stability, high foaming ratio and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

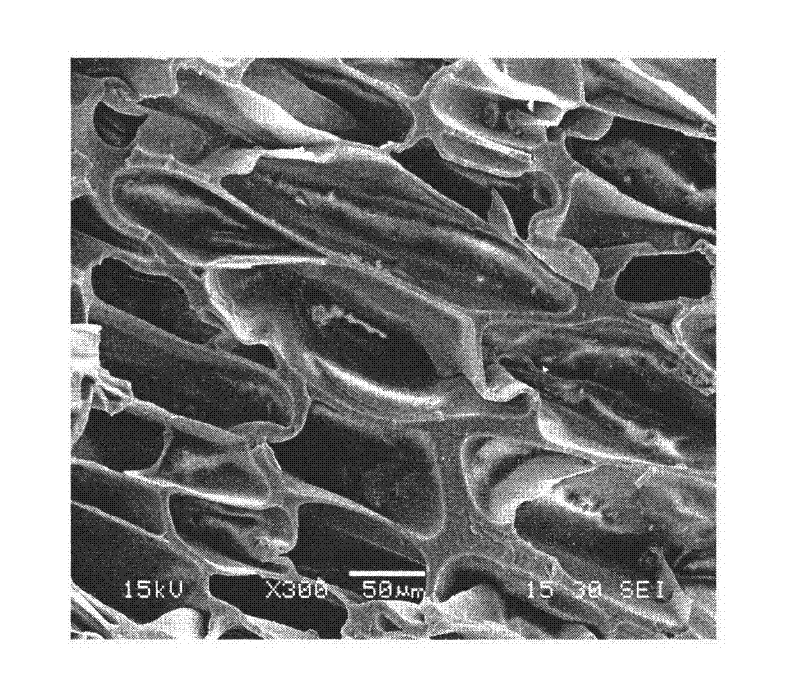

Image

Examples

Embodiment 1

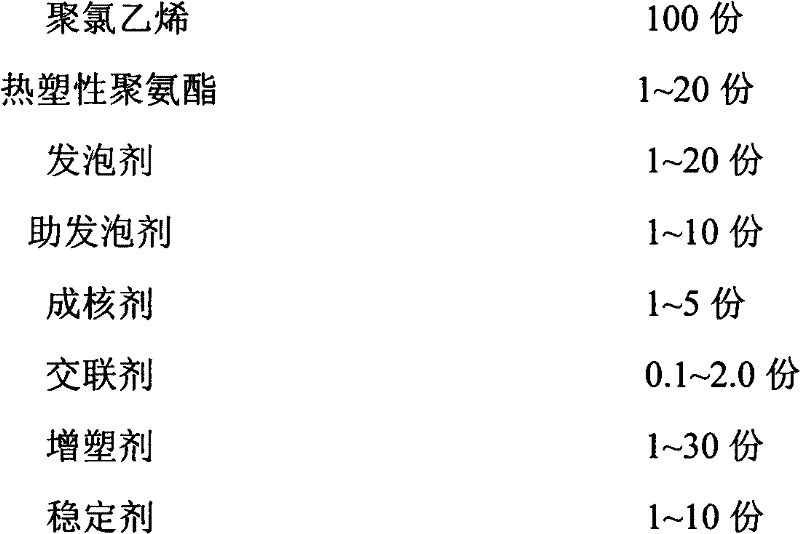

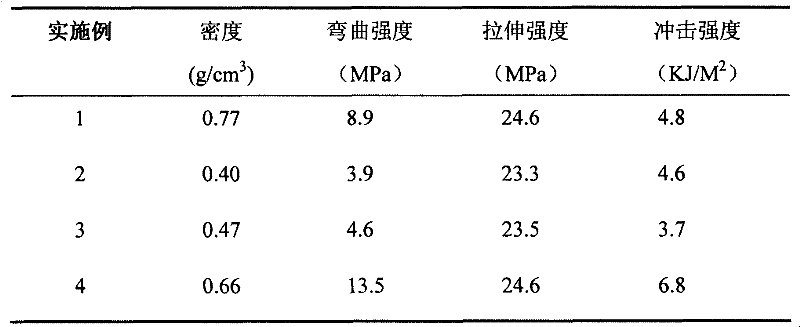

[0032] Each component is weighed in proportion to prepare a cross-linked polyvinyl chloride / thermoplastic polyurethane lightweight foaming material.

[0033] Pre-plasticization: mix 100g of PVC, 0.5g of dibenzoyl peroxide, 2.0g of azodicarbonamide, 1.0g of zinc oxide, 4g of dioctyl phthalate and 1.0g of calcium oxide, mix them and put them in 100℃ Pre-plasticize in a drying oven or oil bath, stir once every 5 minutes, after the plasticizer is completely absorbed by the polyvinyl chloride resin, cool and set aside;

[0034] Plate preparation: Add 4g of TPU to the pre-plasticized PVC, melt and masticate on a double-roll mill at a temperature of 130°C for 10 minutes; mold it into a plate with a hot press at a temperature of 130°C.

[0035] Cross-linking: Cross-linking was carried out on a hot press at 150° C. for 3 minutes.

[0036] Foaming: Foaming on a hot press at 200°C for 1 minute to prepare a cross-linked polyvinyl chloride / thermoplastic polyurethane lightweight foaming ma...

Embodiment 2

[0038] Each component is weighed in proportion to prepare a cross-linked polyvinyl chloride / thermoplastic polyurethane lightweight foaming material.

[0039] Pre-plasticization: PVC 100g, dicumyl peroxide 1.0g, azodicarbonamide 8.0g, dinitrosopentamethylenetetramine 3.0g, zinc stearate 3.0g, phthalic acid di 8g of octyl ester and 5.0g of white carbon black, after mixing, put it into a 100°C drying oven or oil bath for pre-plasticization, stir once every 3 minutes, after the plasticizer is completely absorbed by the polyvinyl chloride resin, cool and set aside;

[0040] Sheet material preparation: Add 8g of TPU to the pre-plasticized PVC, melt and masticate on a double-roll mill at a temperature of 120°C for 12 minutes. A hot press is molded into a plate, and the molding temperature is 140°C.

[0041] Cross-linking: Cross-linking was carried out on a hot press at 160° C. for 10 minutes.

[0042] Foaming: Foaming on a hot press at 210° C. for 3 minutes to prepare a cross-linke...

Embodiment 3

[0044] Each component is weighed in proportion to prepare a cross-linked polyvinyl chloride / thermoplastic polyurethane lightweight foaming material.

[0045] Pre-plasticization: PVC 100g, triallyl cyanurate 2.0g, sodium bicarbonate 5.0g, azodicarbonamide 5.0g, lead stearate 10g, dibutyl phthalate 12g and calcium carbonate 2.0g, after mixing, put it into a 110°C drying oven or oil bath for pre-plasticization, stir once every 3 minutes, after the plasticizer is completely absorbed by the polyvinyl chloride resin, cool and set aside;

[0046] Plate preparation: Add 12g of TPU to the pre-plasticized PVC, melt and knead in an internal mixer, the plasticizing temperature is 110°C, and the time is 15 minutes. It is molded into a plate in a hot press, and the molding temperature is 100°C.

[0047] Cross-linking: Cross-link for 5 minutes at 160°C on a hot press.

[0048] Foaming: Foaming is carried out in an oil bath at 180° C. for 20 minutes to prepare a cross-linked polyvinyl chlorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com