Nitrile rubber microcellular foaming material and its preparation method

A technology of microcellular foaming material and nitrile rubber, which is applied in the field of polymer materials and can solve the problems of formamide residue and limitation of foaming agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

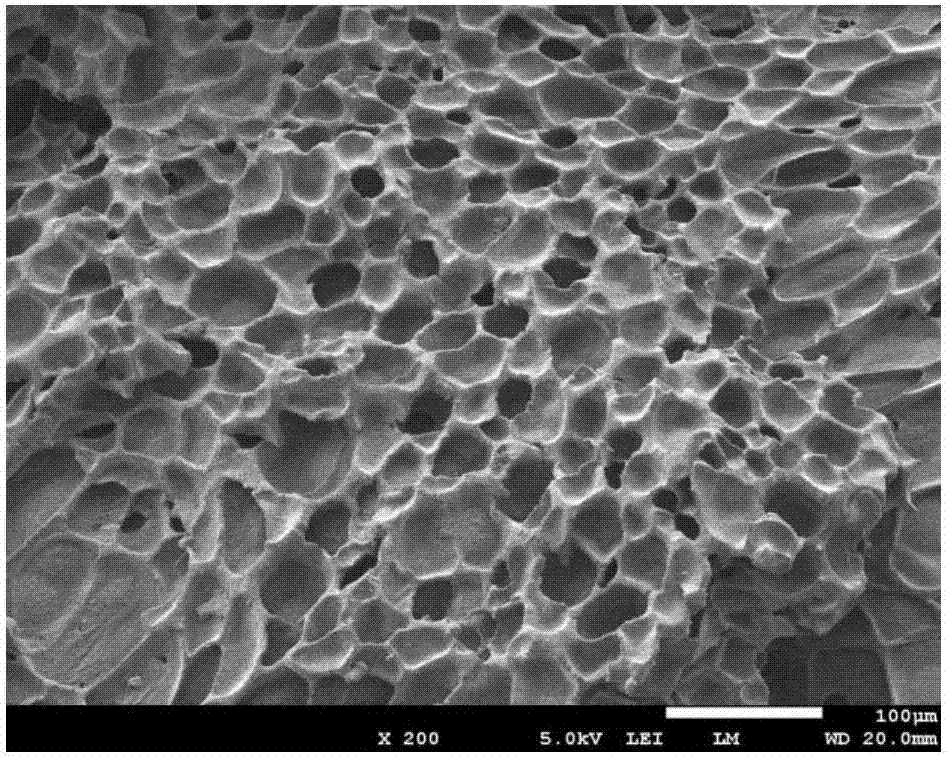

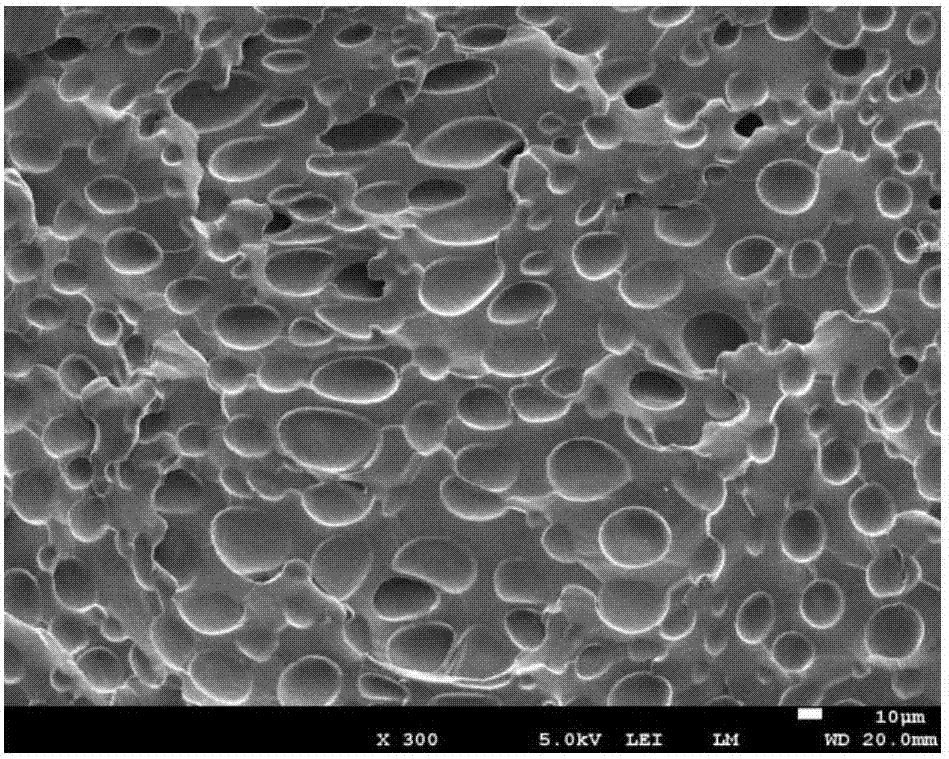

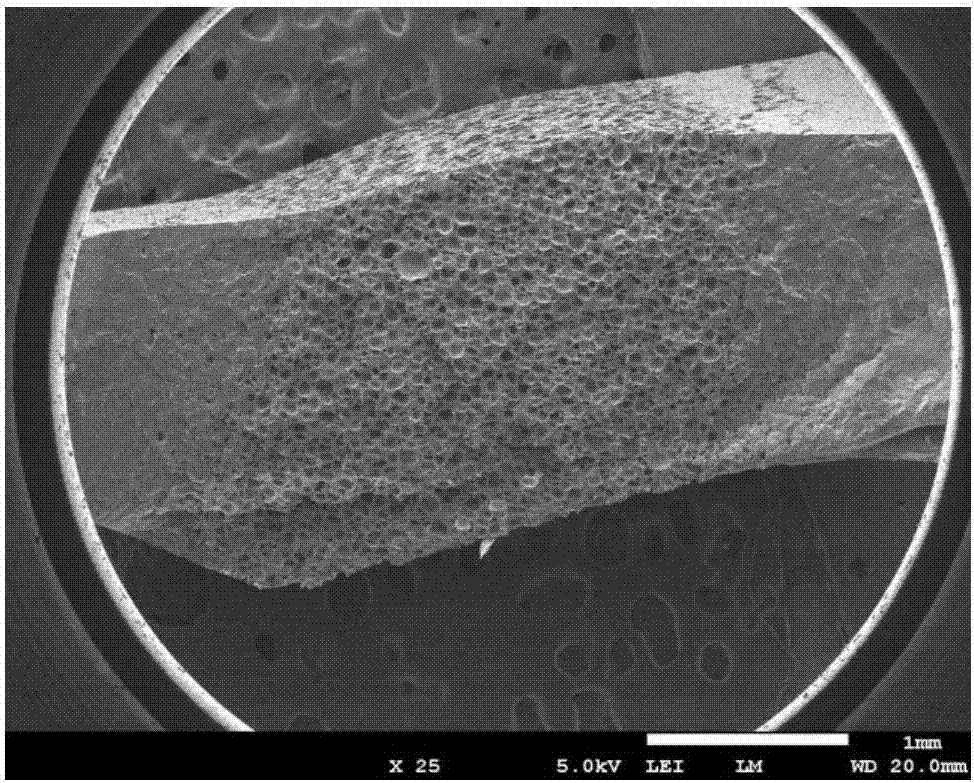

Image

Examples

Embodiment 1

[0036] 100 parts of NBR, 10 parts of filler, 1 part of anti-aging agent 4010, 2 parts of vulcanizing agent, 2.5 parts of vulcanization accelerator, and 3 parts of active agent.

[0037] Wherein, the filler is carbon black; the vulcanizing agent is sulfur, the vulcanization accelerator is TMTD, CZ; the active agent is stearic acid and zinc oxide used together.

[0038] First, the NBR rubber is masticated on the open mill, and then fillers, softeners, vulcanization accelerators are added, and the vulcanization agent is added last. After three thin passes, the sheet is produced to obtain a mixed rubber. After the rubber is placed for one day, it is re-milled. Put the mixed rubber into the required mold, the pressure of the vulcanizer is 10MPa, the temperature is 140°C, and the pre-vulcanization time is 10min. After that, put the pre-vulcanized material into the autoclave, and then seal it. The temperature of the reactor is 60°C, and the N 2 Inject into the autoclave, make the ...

Embodiment 2

[0041] 100 parts of HNBR, 1 part of anti-aging agent 4010, 2.5 parts of vulcanizing agent, 1.5 parts of vulcanization accelerator, and 6 parts of active agent.

[0042] Wherein, the vulcanizing agent is sulfur, the vulcanization accelerator is TMTD; the active agent is stearic acid and zinc oxide used in combination.

[0043] First, the NBR rubber is masticated on the open mill, and then fillers, softeners, vulcanization accelerators are added, and the vulcanization agent is added last. After three thin passes, the sheet is produced to obtain a mixed rubber. After the rubber is placed for one day, it is re-milled. Put the mixed rubber into the required mold, the pressure of the vulcanizer is 10MPa, the temperature is 140°C, and the pre-vulcanization time is 12min. After that, put the pre-vulcanized material into the autoclave, and then seal it. The temperature of the reactor is 60°C, and the N 2 Inject into the autoclave, make the pressure reach 18MPa, and saturate at const...

Embodiment 3

[0046] 100 parts of XNBR, 15 parts of filler, 3 parts of plasticizer, 1.5 parts of antioxidant 4010, 1 part of vulcanizing agent, 1.5 parts of vulcanization accelerator, and 3 parts of active agent.

[0047] Wherein, the filler is carbon black; the plasticizer is aromatic hydrocarbon oil; the vulcanizing agent is dicumyl peroxide; the vulcanization accelerator is TAIC; the active agent is stearic acid and zinc oxide used together.

[0048] First, the NBR rubber is masticated on the open mill, and then fillers, softeners, vulcanization accelerators are added, and the vulcanization agent is added last. After three thin passes, the sheet is produced to obtain a mixed rubber. After the rubber is placed for one day, it is re-milled. Put the mixed rubber into the required mold, the pressure of the vulcanizer is 10MPa, the temperature is 150°C, and the pre-vulcanization time is 8min. After that, put the pre-vulcanized material into the autoclave, and then seal it. The temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com