Anti-explosion cover cap assembly of power lithium battery

A lithium battery and explosion-proof cover technology, which is applied to battery pack parts, battery cover/end cover, electrical components, etc., can solve the problems of poor reliability of the explosion-proof disc 20, damage of the explosion-proof disc 20, and short service life of the battery. Achieve the effect of eliminating the wrapping process, good CPK value and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

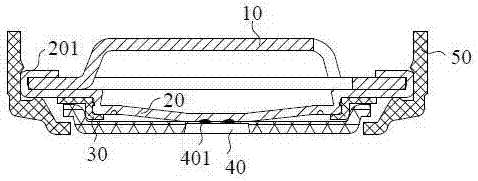

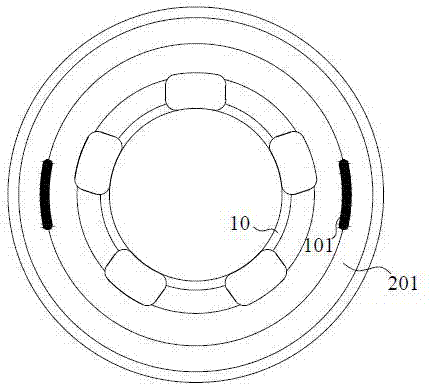

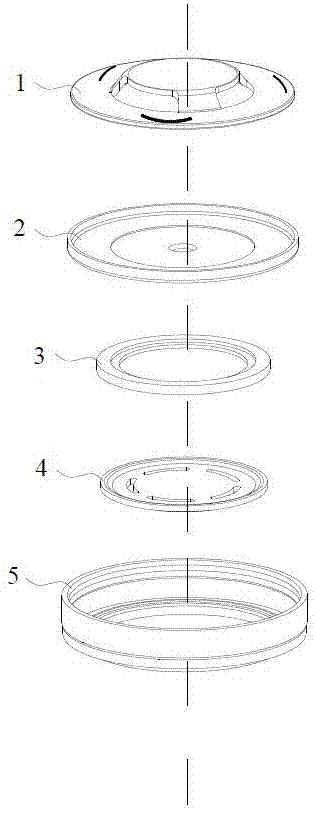

[0031] Such as Figures 3 to 9 As shown, a power lithium battery explosion-proof cap assembly includes a top cover 1, an explosion-proof sheet 2, an insulating ring 3, an orifice plate 4 and a sealing ring 5 from top to bottom. A laser welding line 11 is used for welding the explosion-proof plate 2 and the top cover 1 . The top cover and the explosion-proof plate are welded and connected by laser welding wire 11, no need to figure 1 The encapsulation structure 201 shown not only eliminates the encapsulation process, so that the explosion-proof plate is protected from secondary damage caused by the encapsulation process, but also the laser welding line 11 is more beautiful and has high reliability, which further enhances safety. At the same time, since the overall height of the cap is reduced, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com