Equipment used for machining three-dimensional externally finned tubes

A ribbed tube and equipment technology, which is applied in the field of equipment for processing three-dimensional outer ribbed tubes, can solve the problems of reducing the strength of the workpiece, heat dissipation effect, poor consistency of angle and thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

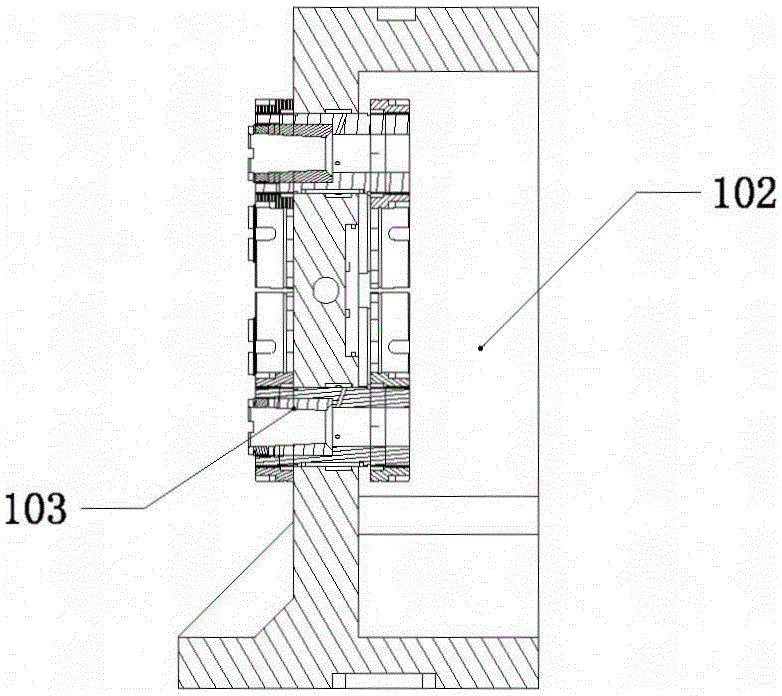

[0034] like Figure 9 , Figure 10 As shown: the workpiece feeding device 3 includes a sleeve 302 and a rotatable connecting rod 303, and also includes a fixed block 301. The end of the connecting rod 303 is connected with a connecting rod 304, and the front end of the connecting rod 303 is provided with a clamping platform 305, and the sleeve 302 is sleeved outside the connecting rod 303, the diameter of the card table 305 is greater than the diameter of the connecting rod 303, the outer wall of the card table 305 is threadedly connected with the workpiece, and the outer wall of the connecting rod 304 at the end of the connecting rod 303 is threadedly connected with a tensioning fixture; The outer wall of the front end of 302 and the outer wall of card table 305 are provided with the same thread, and the thread section of the inner wall of the workpiece is provided with two smooth sections 306 of pitch length. Between the front end of the barrel 302 and the card table 305; t...

Embodiment 2

[0037] Compared with the first embodiment of the workpiece feeding device 3, the oil cylinder 307 in the first embodiment is replaced by an air cylinder.

[0038] 4 embodiments of locking device in the present invention:

[0039] like Figure 11 Shown: the locking device 4 connected with the workpiece feeding device 3, the upper part of the frame 2 includes a slide rail 402 with a boss 401 on the inside or outside of the upper part, and the locking device 4 is located on the slide rail 402; the locking device 4 It includes a slider 403 that is slidably matched with the upper end of the boss 401 of the slide rail 402, a pressure block 404 that is slidably matched with the lower end of the boss 401 of the slide rail 402, a cylinder 405 and a spring 406 that are arranged on the slider 403, and the spring 406 One end is connected to the pressing block 404 , the other end of the spring 406 is connected to the sliding block 403 ; a sliding rod 407 is disposed inside the cylinder 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com