Phenolic glass steel and subway evacuation platform made of same

An evacuation platform and fiberglass technology, which is applied to mining equipment, earthwork drilling, safety devices, etc., can solve the problems of easy jamming of passengers' heels, hindering passengers from escaping, and jumping up to the platform, so as to achieve the goal of not getting stuck in the heels, Great escape time, the effect of leveling the platform surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 Grid-type phenolic fiberglass evacuation platform

[0046] Production of phenolic FRP: 75 parts by weight of glass fiber yarn, 5 parts by weight of continuous glass fiber mat, 18 parts by weight of phenolic resin, 0.9 part by weight of curing agent, 0.55 part by weight of accelerator, and 0.55 part by weight of ferric oxide. The process is prepared, wherein the temperature of the pultrusion die is 220°C to 280°C.

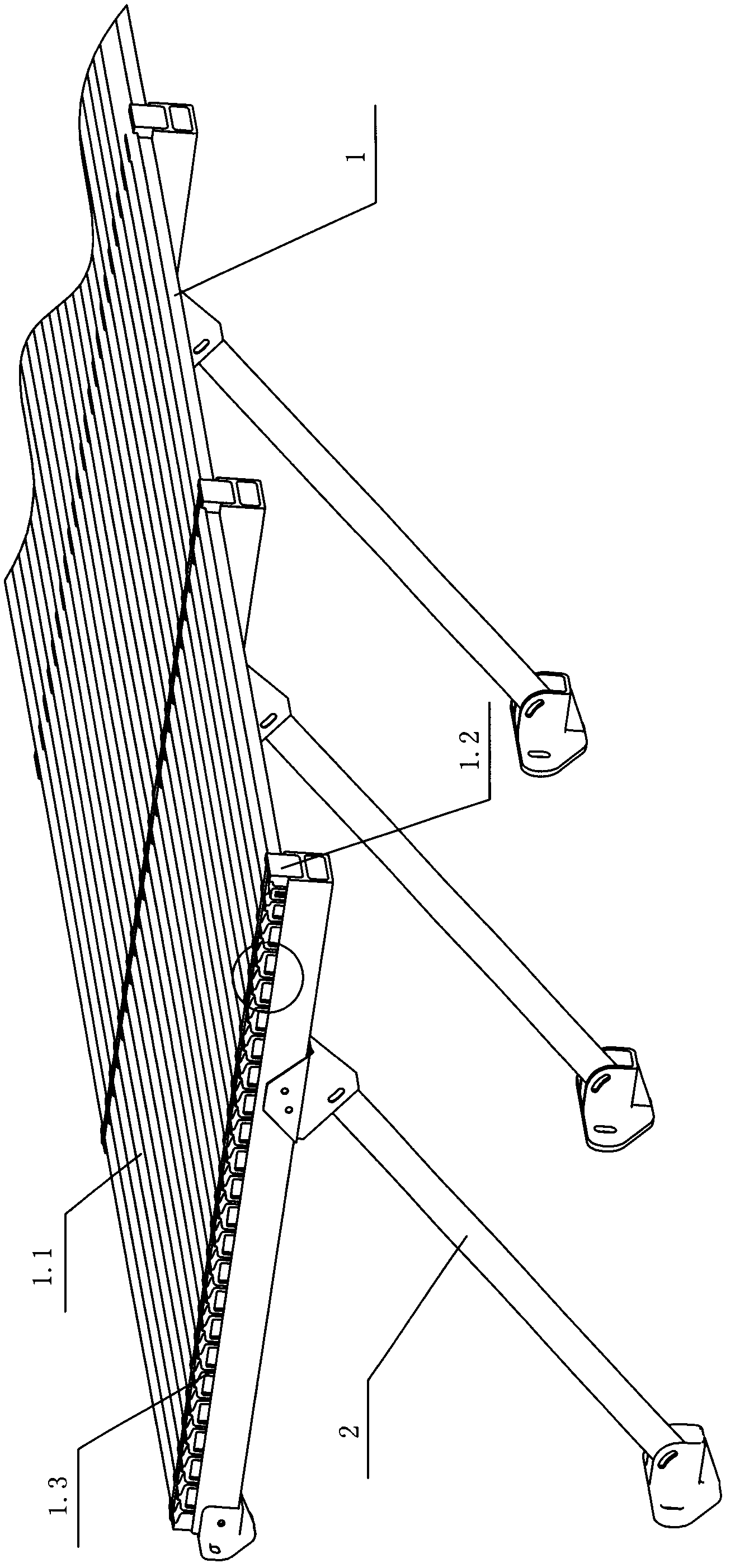

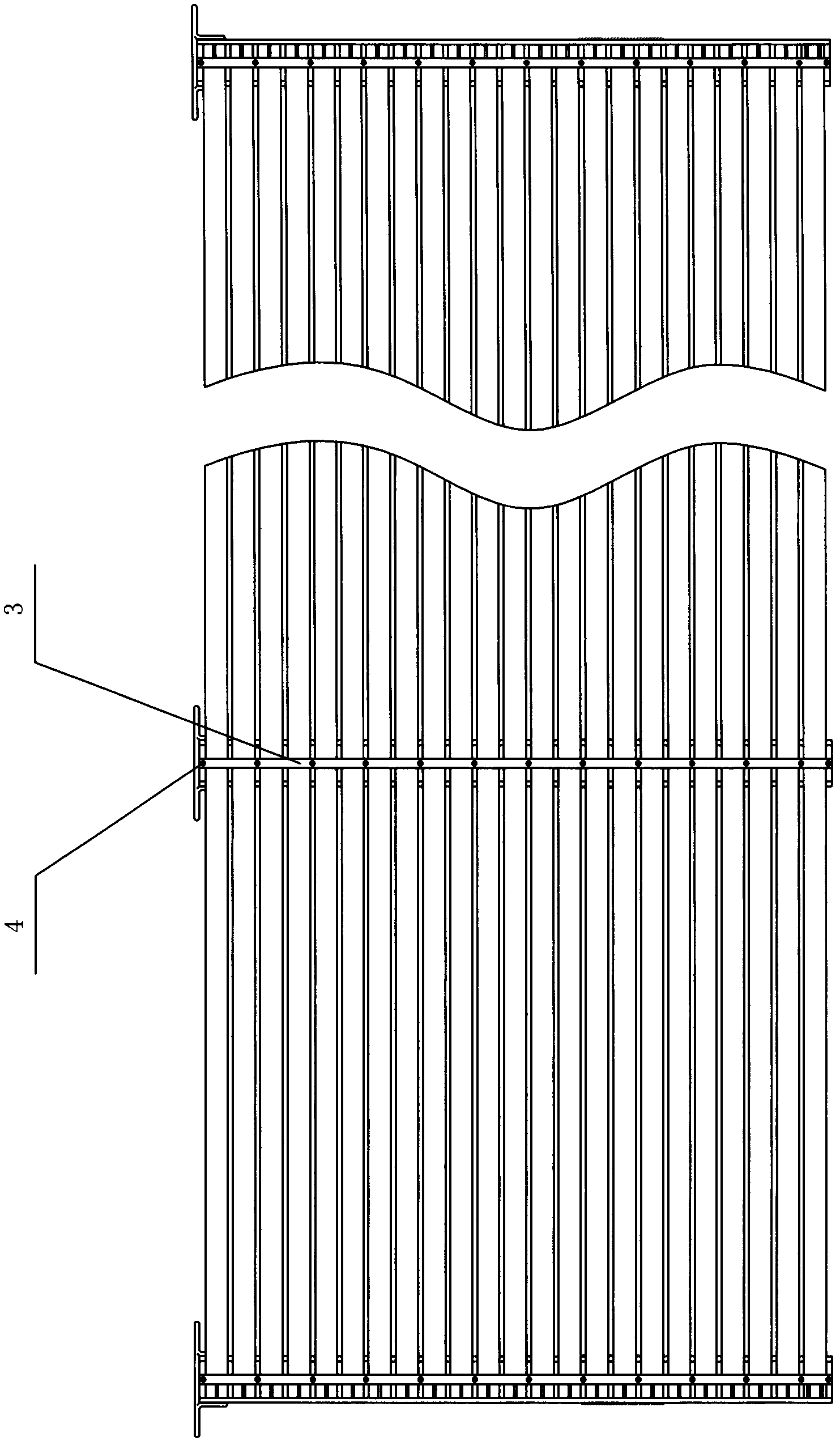

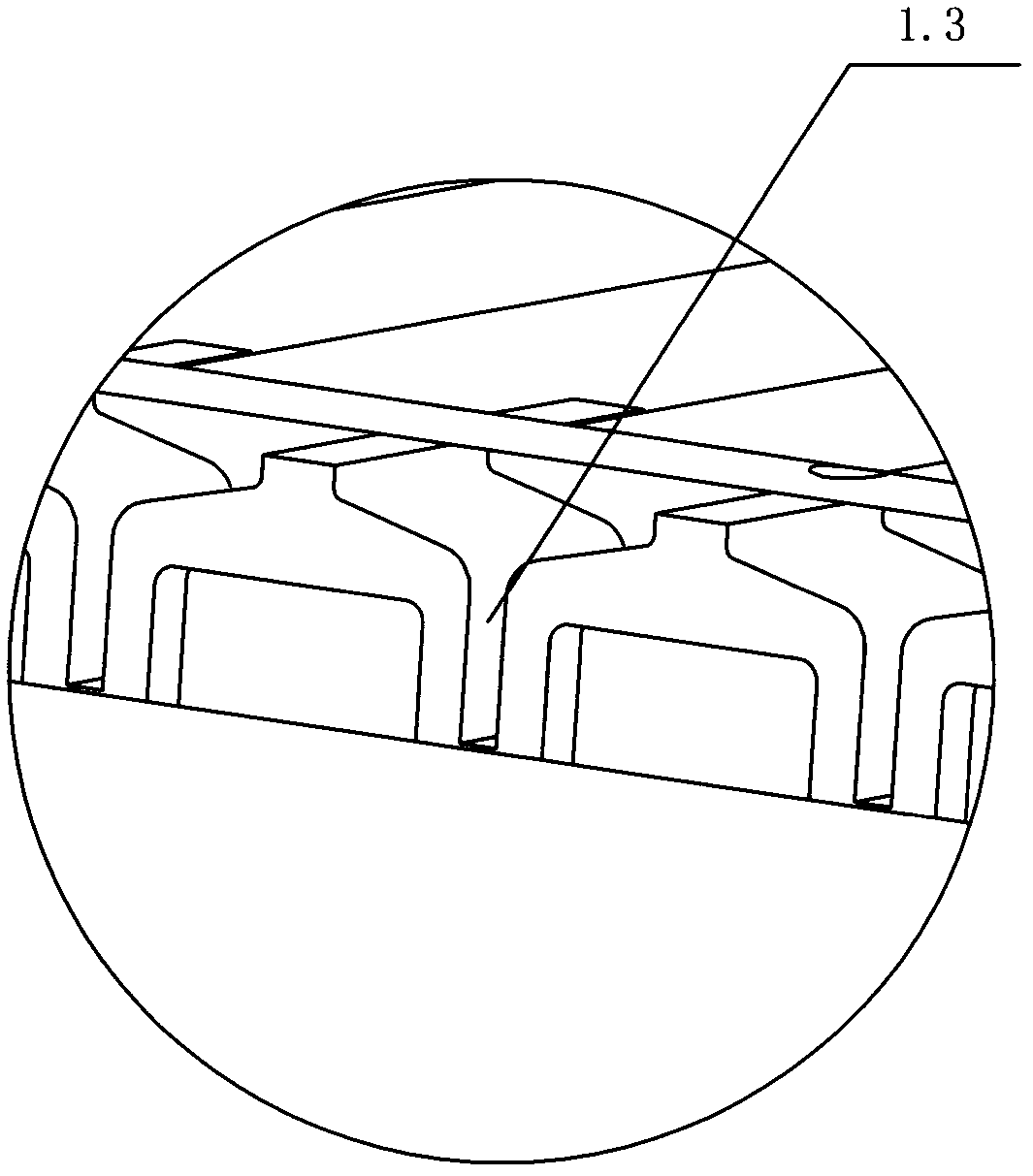

[0047] Such as figure 1 , 2 , 3 and 4, the grid-type evacuation platform made of the above-mentioned pultruded phenolic glass steel includes a table top 1 and a support 2 fixedly connected under the table top 1, and the table top 1 includes several closely arranged longitudinal beams 1.1 and a plurality of horizontally arranged beams 1.2, the cross-section of the longitudinal beams 1.1 is T-shaped, and the longitudinal beams 1.1 with T-shaped cross-sections are arranged at intervals to form grid-like flat plates. The beam 1.2 is provided with ...

Embodiment 2

[0048] Embodiment 2 flat phenolic fiberglass evacuation platform

[0049] Production of phenolic FRP: 76 parts by weight of glass fiber yarn, 4 parts by weight of continuous glass fiber mat, 19 parts by weight of phenolic resin, 0.9 part by weight of curing agent, 0.55 part by weight of accelerator, and 0.55 part by weight of ferric oxide. It is made by pultrusion process, and the temperature of the pultrusion die is 220℃~280℃.

[0050]Such as Figure 5 , 6 Shown in , 7, a flat-plate subway evacuation platform prepared by the above-mentioned phenolic glass fiber reinforced plastics, comprising a table top 1 and a support 2 fixedly connected under the table top 1, the support 2 is a triangular support, and the table top 1 has no gap on the upper surface The flat surface 5 and the bottom of the flat surface 5 are provided with support strips 6 integrally formed with the flat surface at intervals and side by side, and the flat surface 5 is traversed by several piercing beams 7;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com