Inorganic thermal insulation decorative sheet and installation method thereof

A technology of inorganic thermal insulation and installation method, applied in the field of decorative materials, can solve the problems of weak adhesion, damage to inorganic thermal insulation decorative panels, cracking of the board body, etc., to improve stability and firmness, low manufacturing cost, and avoid dust accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

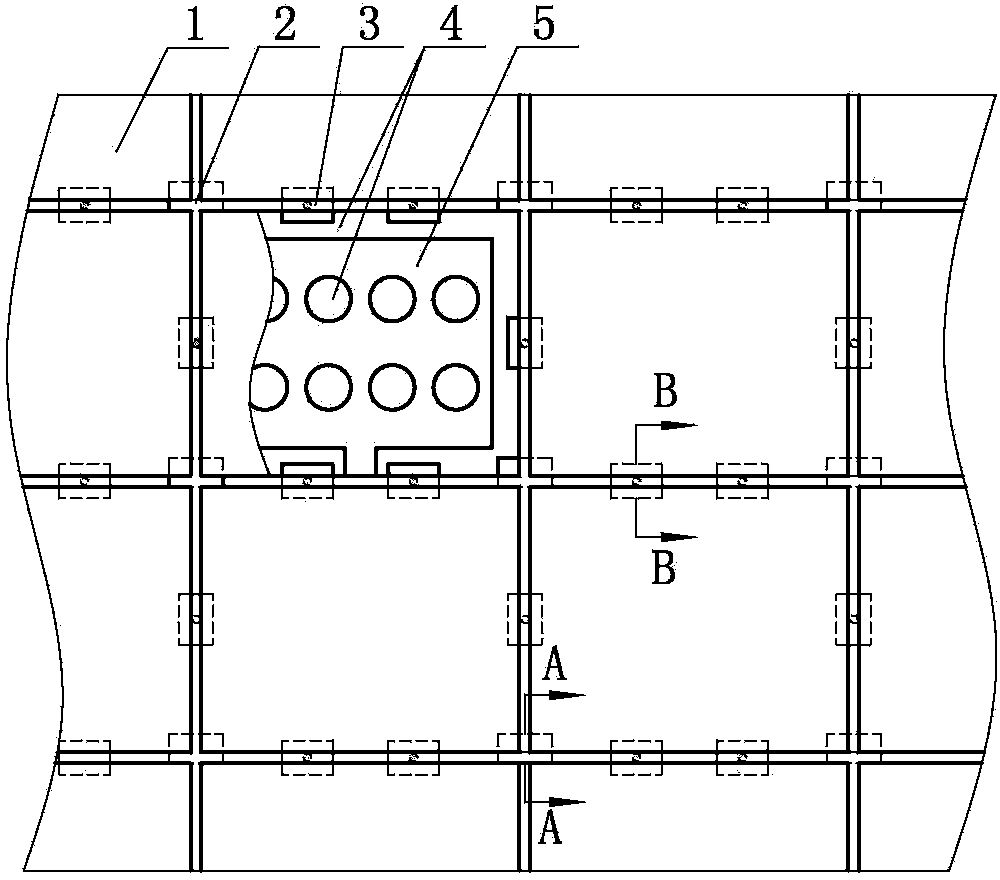

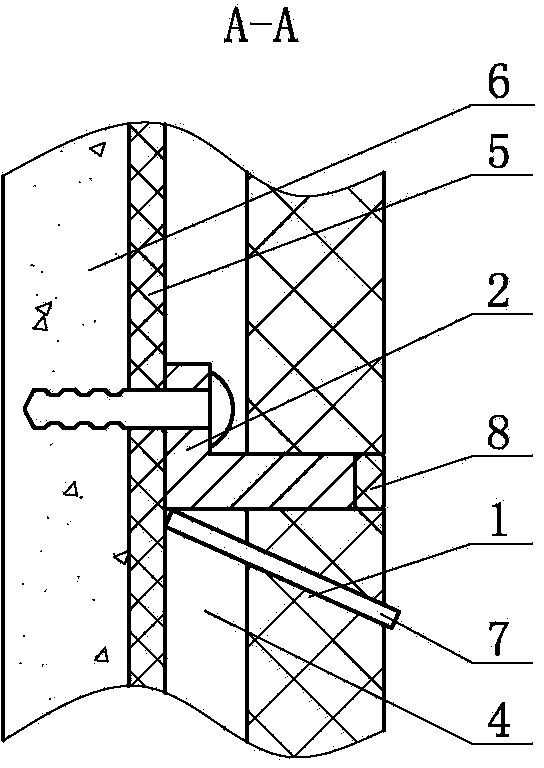

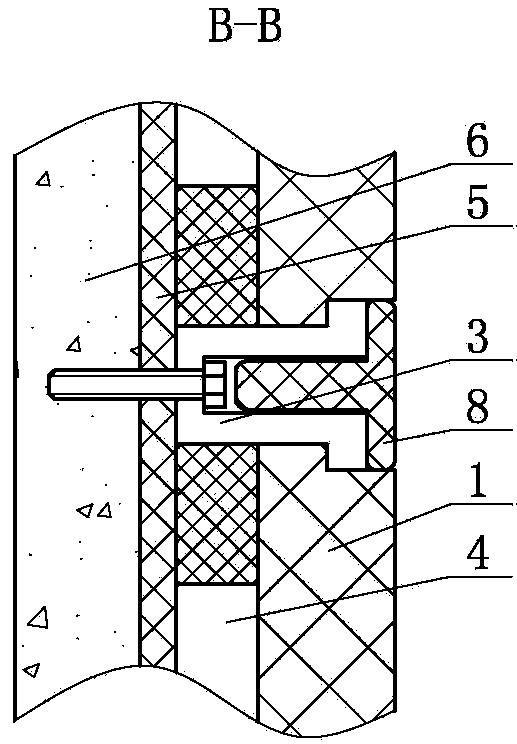

[0013] A kind of inorganic thermal insulation decorative board, such as figure 1 with figure 2 As shown, it includes a leveling layer 5 on the wall surface of the base wall body 6. The leveling layer is the treatment of the wall surface, and construction on a flat surface can improve the stability and firmness of the thermal insulation decorative board. An L-shaped bracket 2 is anchored on the wall of the base wall 6. The bracket 2 is composed of a horizontal plate and a vertical plate. The L-shaped bracket 2 is 40mm×40mm galvanized angle steel, which is strong and anti-corrosion , the vertical plate of the support 2 is anchored on the base wall 6, the L-shaped support 2 is anchored parallel to the base wall 6, and forms a horizontal plate after it is completely fitted with the base wall 6, and the L-shaped support is connected with the leveling Layer cooperation, because the leveling layer is a vertical surface, so the horizontal plate of the L-shaped bracket can be kept ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com