Speaker module

A speaker module and speaker technology, applied in speaker screen, speaker transducer fixing, sensor and other directions, can solve the problems of reducing the service life of the module, difficult sealing, low product qualification rate, etc. The effect of reducing the difficulty of processing and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

[0033] The orientation mentioned in this manual refers to the direction of the vibration system of the speaker unit, and the direction below refers to the direction of the magnetic circuit system of the speaker unit; the inner side referred to in this manual refers to the inner cavity of the module or the inner cavity of the monomer. The inner side and the outer side both refer to the side outside the inner cavity of the module or the inner cavity of the monomer.

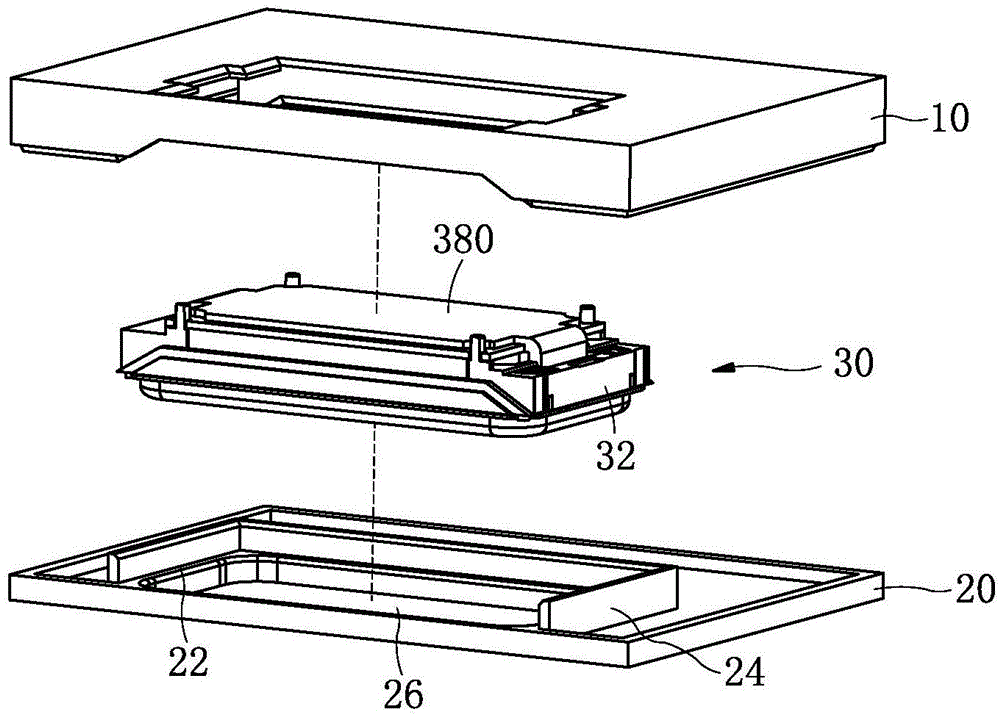

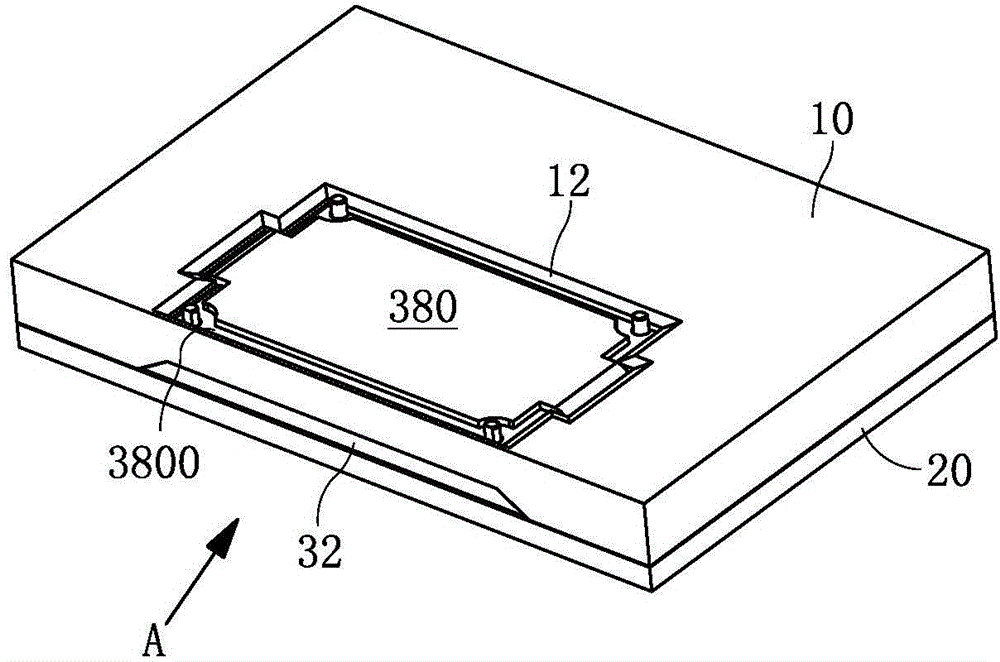

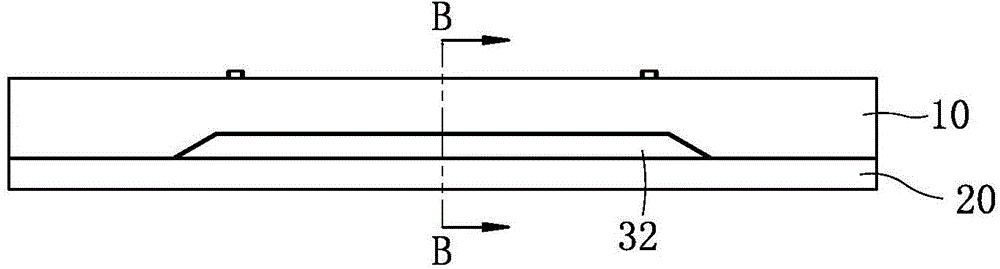

[0034] Such as figure 1 and figure 2Commonly shown, a loudspeaker module has a rectangular structure and includes a casing. The casing is composed of an upper casing 20 and a lower casing 10 combined together. A speaker unit 30 is accommodated in the space enclosed by the upper casing 20 and the lower casing 10. The loudspeaker unit 30 is also a rectangular structure, and the loudspeaker unit 30 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com