Underground pipeline protection device and support method applying underground pipeline protection device

A technology for underground pipelines and protection devices, applied in underground chambers, shaft equipment, earthwork drilling and mining, etc., can solve the problems of damaged pipelines, long construction period of pipelines, small distance between pipelines and tunnels, etc., and achieve strong bearing capacity and stability , The construction method is simple and the effect of shortening the working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

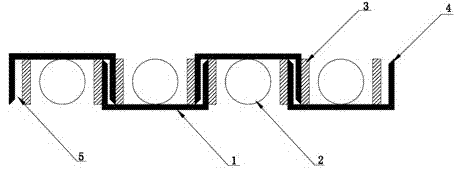

[0025] Example 1, such as Figure 1-2 As shown, an underground pipeline protection device described in the embodiment of the present invention is composed of a plurality of channel steels 1 interlocked with each other, and the opening directions of adjacent channel steels are opposite. There are grouting holes in the pipe wall.

[0026] Further, vertical steel plates 3 are welded on both sides of the inner grouted steel pipe of the channel steel, and a fastening space 5 is formed between the vertical steel plates and the side plates of the channel steel.

[0027] Further, one end of the channel steel and the grouted steel pipe is ground into a tapered structure.

[0028] Further, the end of the side plate of the channel steel is ground into a sharp corner 4 .

[0029]In the above-mentioned embodiment, the present invention horizontally arranges positive and negative close-knit channel steels close to the pipeline below the pipeline to form a horizontal plate-like airtight is...

Embodiment 2

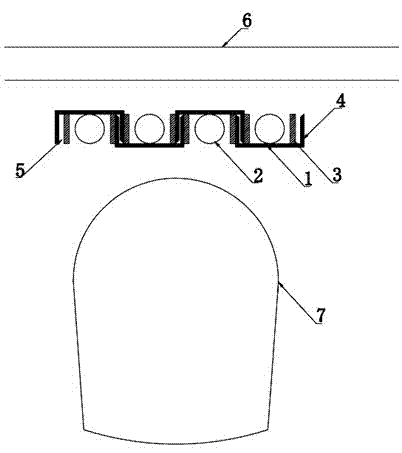

[0030] Example 2, such as figure 2 As shown, an embodiment of the present invention also provides a support method using an underground pipeline protection device, and the support method includes the following steps:

[0031] 501: Before excavation of tunnel 7, make construction preparations, set up probes for advanced detection before channel steel drilling, and determine the specific position of pipeline 6; set up probes for advanced detection before channel steel drilling Main purpose The following are: first, to determine the specific location of the pipeline, to prevent the channel steel from being damaged by touching the pipeline during the jacking process; second, to ascertain the soil quality and water seepage. For example: after advanced detection, the minimum distance between the pipeline and the excavation line of the tunnel vault is less than 200mm, the soil is silty clay, and the probe has a little seepage and open flow and has a strange smell. Then, according to...

specific Embodiment

[0046] Specific embodiments: the device provided by the present invention is used in the support of subway tunnels. Through practice, four entrances and exits of subway stations have passed through sewage pipelines safely and smoothly, ensuring construction safety and pipeline safety. After passing through the pipeline, the subsidence caused by the subsidence led to aggravated water seepage. Water blocking treatment was carried out on site in a timely manner. At the same time, a water diversion pipe was installed on the vault plug of the elevated section. The water flow in the water pipe was relatively large, and the sealing was carried out before the lining was closed. The blockage did not cause adverse effects on the project.

[0047] After monitoring, the maximum settlement value of the vault is 10.98mm, the maximum settlement value of the ground surface is 12.46mm, and the maximum settlement value of the pipeline is 7mm, all of which have not reached the warning value and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com