Preparation method of white water-resistant and oil-proof paper

An oil-proof paper, white technology, applied in the field of papermaking, can solve the problems of poor thickness of high-strength paper, insufficient oil resistance of oil-proof paper, poor waterproof performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

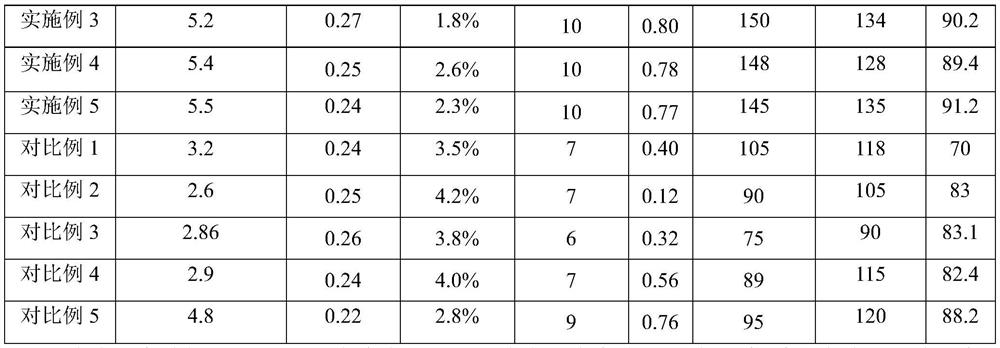

Examples

Embodiment 1

[0037] A preparation method of white water-resistant and oil-proof paper, comprising the following steps:

[0038] (1) Preparation of base paper: after 60% bleached softwood pulp and 40% bleached hardwood pulp are chemically soaked, beating to 65 ° SR; get 45 parts by weight of bleached chemical pulp, 5 parts by weight of filler talcum powder and 5 parts by weight After the cationic starch is mixed, the wire part is dehydrated, squeezed and dried to obtain base paper; the chemical pulp soaking time of the bleached slurry is 4h; the squeezing condition is 450kPa, 10-15min;

[0039] (2) Coating for the first time: Chitosan-vermiculite solution is coated on the base paper of step (1) gained, coating amount is 3g / m 2 The preparation step of described chitosan cellulose-vermiculite solution comprises: chitosan cellulose is added in the glacial acetic acid solution that the pH value of deployment is 3.5, stirs until chitosan cellulose dissolves completely, nanometer Grade vermiculi...

Embodiment 2

[0045] The difference with Example 1 is that a preparation method of white water-resistant and grease-proof paper comprises the following steps:

[0046] (1) Preparation of base paper: after chemical soaking of 55% bleached softwood pulp and 45% bleached hardwood pulp, beating to 70 ° SR; get 50 parts by weight of bleached chemical pulp, 6 parts by weight of filler calcium carbonate and 6 parts by weight After the cationic starch is mixed, the wire part is dehydrated, squeezed and dried to obtain base paper; the chemical pulp soaking time of the bleached slurry is 4.5h; the squeezing condition is 480kPa, 11min;

[0047] (2) Coating for the first time: Chitosan-vermiculite solution is coated on the base paper of step (1) gained, coating amount is 5g / m 2 The preparation step of described chitosan cellulose-vermiculite solution comprises: chitosan cellulose is added in the glacial acetic acid solution that the pH value of deployment is 3.8, stirs until chitosan cellulose dissolve...

Embodiment 3

[0053] The difference with Example 1 is that a preparation method of white water-resistant and grease-proof paper comprises the following steps:

[0054] (1) Preparation of base paper: after chemical soaking of 50% bleached softwood pulp and 50% bleached hardwood pulp, beating to 72 ° SR; get 60 parts by weight of bleached chemical pulp, 7 parts by weight of filler titanium dioxide and 7 parts by weight of After the cationic starch is mixed, the wire part is dehydrated, squeezed, and dried to obtain base paper; the chemical pulp soaking time of the bleached slurry is 5h; the pressing condition is 520kPa, 13min;

[0055] (2) Coating for the first time: Chitosan-vermiculite solution is coated on the base paper of step (1) gained, coating amount is 8g / m 2 The preparation step of described chitosan cellulose-vermiculite solution comprises: chitosan cellulose is added in the glacial acetic acid solution that the pH value of deployment is 4, stirs until chitosan cellulose dissolves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com