Method for preparing BaTiO3 / multi-wall carbon nano-tube (MWCNTs) nano composite material

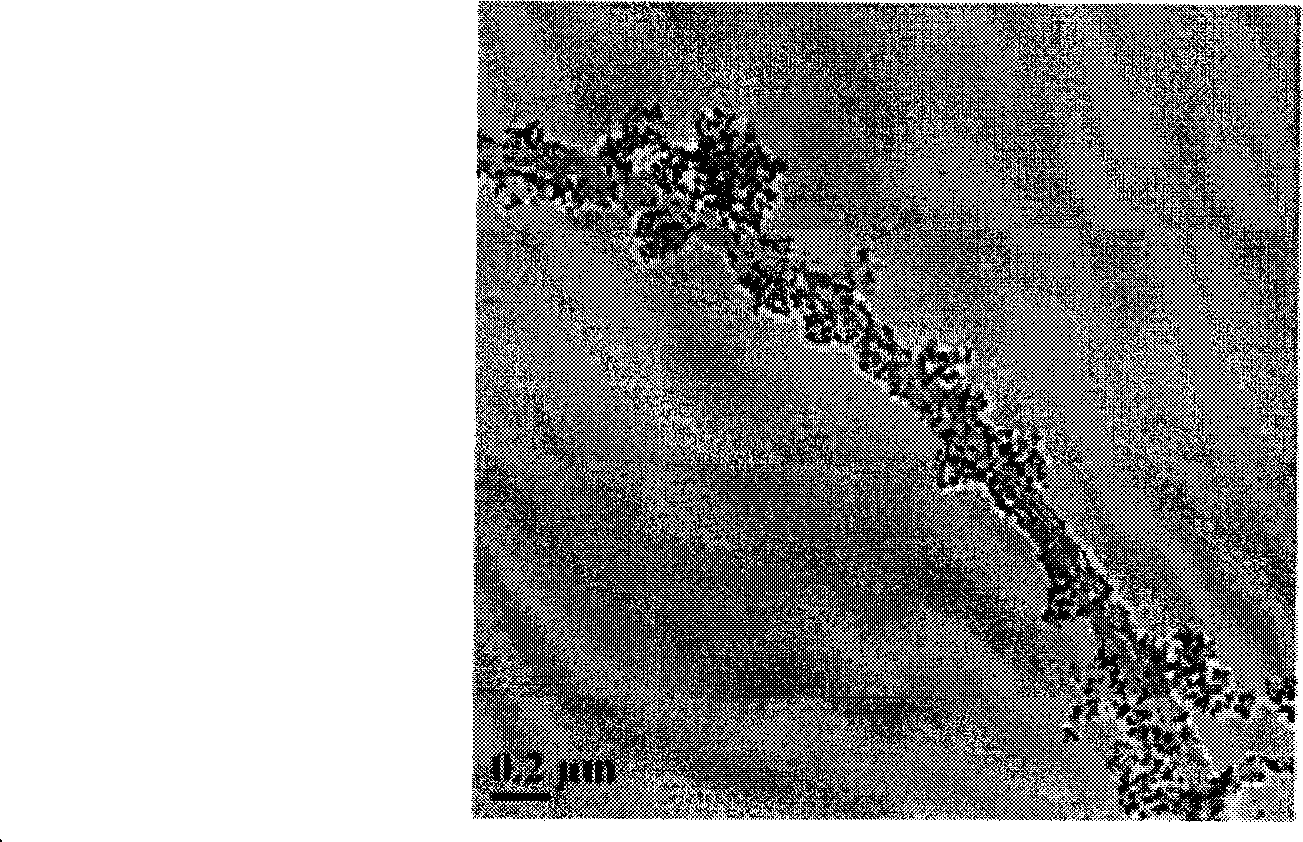

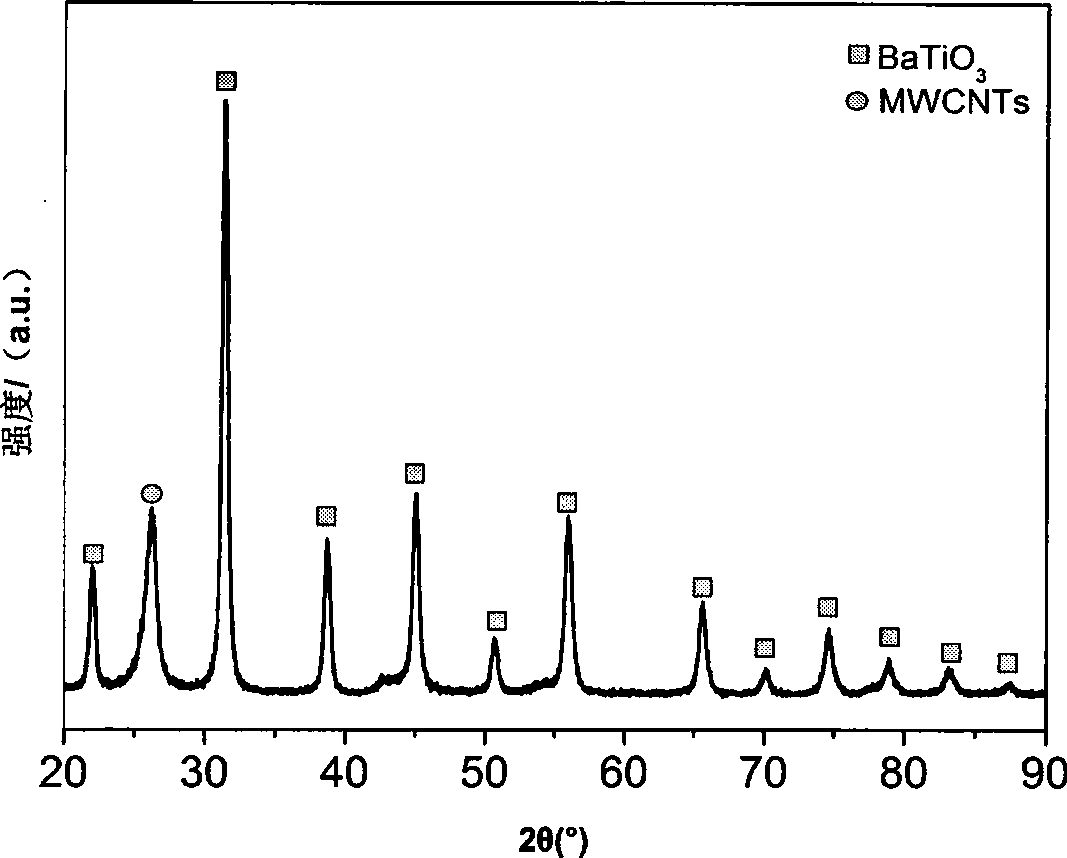

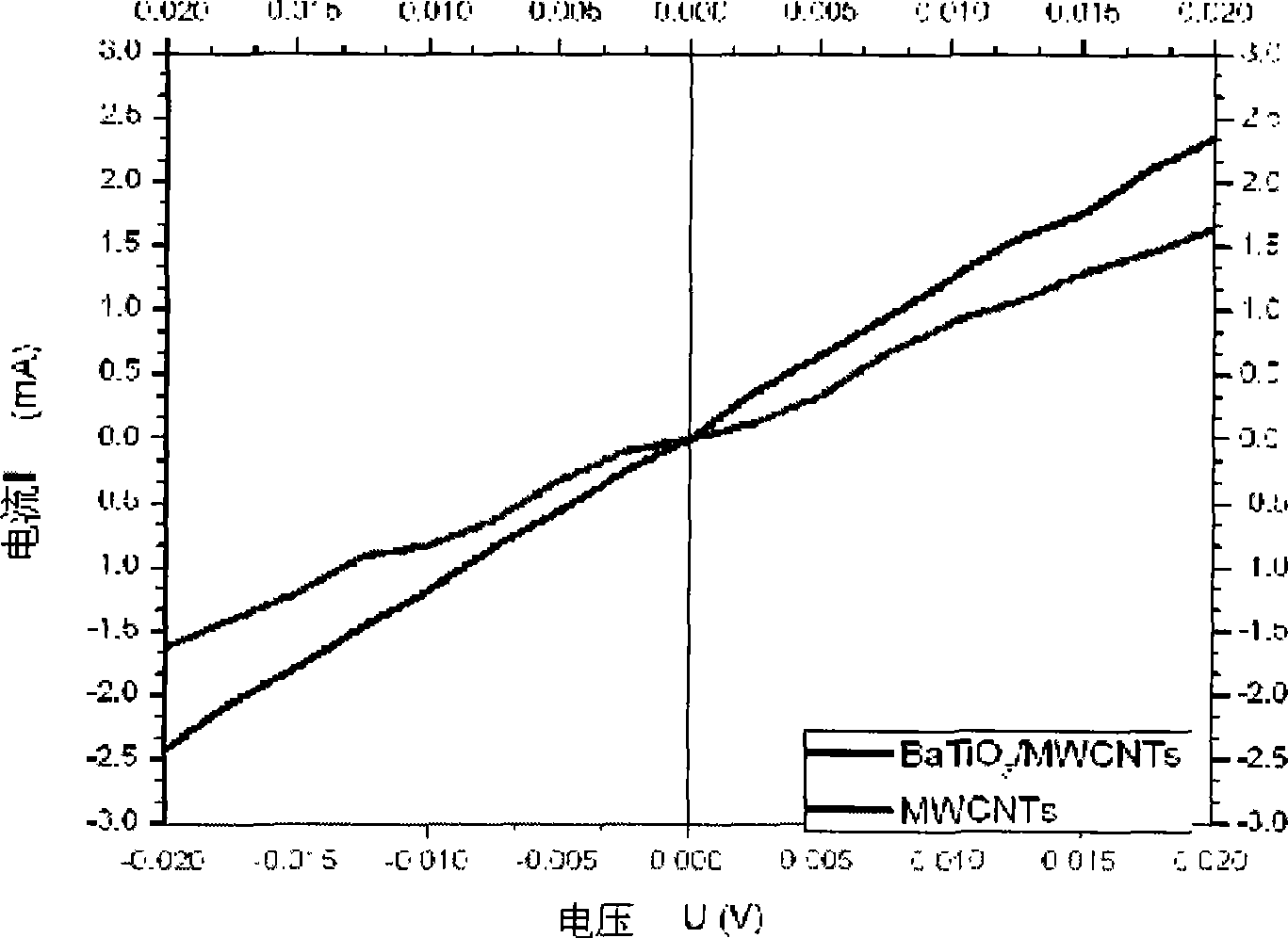

A technology of multi-walled carbon nanotubes and nanocomposite materials, applied in titanium compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of room temperature resistivity increase, density decrease, electron mobility increase, etc., and achieve simple production equipment. , good crystallization, uniform particle distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Measure 40ml of concentrated nitric acid (15mol / L), and then measure 20ml of deionized water, mix and stir. Then weigh 0.5g MWCNTs into the above solution, ultrasonically disperse for 30min, and then heat to 120°C under magnetic stirring for 24h. After the reaction, the carbon tube suspension was filtered, washed and dried to obtain modified MWCNTs. 1.7 g of tetrabutyl titanate was dropped into a beaker containing 20 ml of absolute ethanol while magnetic stirring was performed. Prepare 0.1 mol / L ammonia solution, slowly drop the ammonia solution into the mixed solution of absolute ethanol and tetrabutyl titanate to obtain white precipitated Ti(OH) 4 , centrifuge and wash the product. The above modified MWCNTs and the generated Ti(OH) 4 Add a three-necked flask, then add 25ml of ethanolamine, 25ml of ethylenediamine, 5ml of deionized water, 3.825g of barium acetate, 2.4g of sodium hydroxide, 1ml of polyethylene glycol, 0.01g of polyvinylpyrrolidone, and the number of r...

Embodiment 2

[0035] Measure 40ml concentrated nitric acid (15mol / L), then measure 20ml deionized water, mix and stir. Weigh 0.4g MWCNTs into the above solution, ultrasonically disperse for 30min, and then heat to 110°C and stir magnetically for 36h. After the reaction, the carbon tube suspension is filtered, washed and dried to obtain modified MWCNTs. 2 g of tetrabutyl titanate was dropped into a beaker filled with 20 ml of absolute ethanol, and magnetic stirring was performed at the same time. Prepare a 0.5mol / L ammonia solution, and slowly drop the ammonia solution into the mixture of absolute ethanol and tetrabutyl titanate to obtain a white precipitate Ti(OH) 4 , Centrifuge and wash the product. The above modified MWCNTs and the generated Ti(OH) 4 Add a three-necked flask, then add 22ml ethanolamine, 22ml ethylenediamine, 5ml deionized water, 4.59g barium acetate, 2.6g sodium hydroxide, 1ml polyethylene glycol, 0.01g polyvinylpyrrolidone, and the rotation speed is 350r / min Stir at l...

Embodiment 3

[0038] Measure 50ml concentrated nitric acid (15mol / L), then measure 25ml deionized water, mix and stir. Weigh 0.5g MWCNTs into the above solution, ultrasonically disperse for 30min, and then heat to 100°C and stir magnetically for 24h. After the reaction, the carbon tube suspension is filtered, washed and dried to obtain modified MWCNTs. 2.7ml of tetrabutyl titanate was dropped into a beaker filled with 20ml of absolute ethanol, and magnetic stirring was performed at the same time. Prepare a 1mol / L ammonia solution, and slowly drop the ammonia solution into the mixture of absolute ethanol and tetrabutyl titanate to obtain a white precipitate Ti(OH) 4 , Centrifuge and wash the product. The above modified MWCNTs and the generated Ti(OH) 4 Add a three-necked flask, then add 25ml ethanolamine, 25ml ethylenediamine, 5ml deionized water, 6.12g barium acetate, 3.2g sodium hydroxide, 1ml polyethylene glycol, 0.01g polyvinylpyrrolidone, and the rotation speed is 350r / min Stir at lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com