Process for preparing plastic hook fastener

A preparation process and technology of hook and loop fasteners, which are applied in the direction of fasteners, press fasteners, press fasteners, etc., can solve the problems of complex manufacturing process, inconvenient operation, and complicated preparation methods of hook and loop fasteners, and achieve strong firmness and long life. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

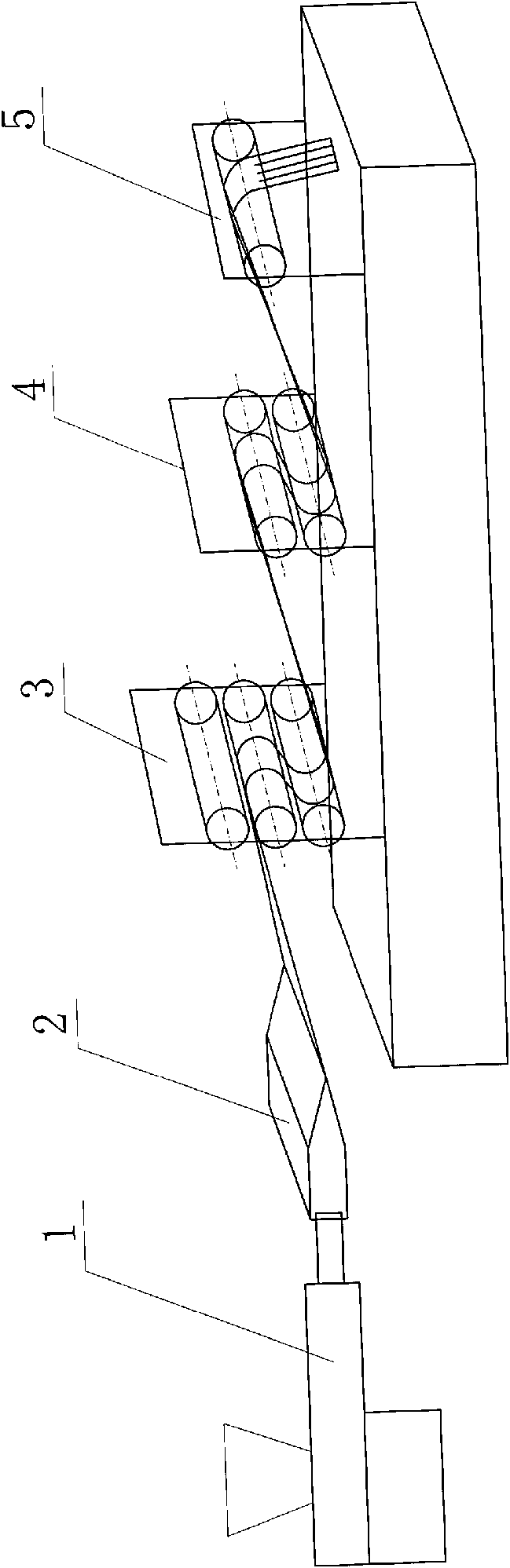

[0007] The accompanying drawings have shown the technical solution of the present invention and its embodiments, and the embodiments and related details thereof will be further described below in conjunction with the accompanying drawings.

[0008] combine figure 1 , the first is to put the toughened nylon (PA6) material into the molten cavity with electric heating and high temperature of the extruder 1 to soften it into a paste. The paste-like material is extruded in the extruder 1 and passed through the smooth sheet mold 2 to become a continuous sheet. At this time, the temperature of the material has dropped to about 130°C, and then enters the traction mechanism and is formed by a gear with high and low hook teeth. Roller 3 rolls on the soft sheet to manufacture hook teeth with two-level difference in length, and then enters flat pressing roller 4 for rolling and shaping. The temperature of the whole process is formed at a constant temperature of about 130°C, and then thes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com