Composite molecular sieve and hydrodesulfurization catalyst prepared with composite molecular sieve as carrier

A compound molecular sieve and hydrodesulfurization technology, which is applied in molecular sieve catalysts, physical/chemical process catalysts, refined hydrocarbon oils, etc., can solve the problems of application limitations, unsatisfactory effects, and high diffusivity, etc., to achieve interaction improvement, Good metal dispersibility, effect of improving metal dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

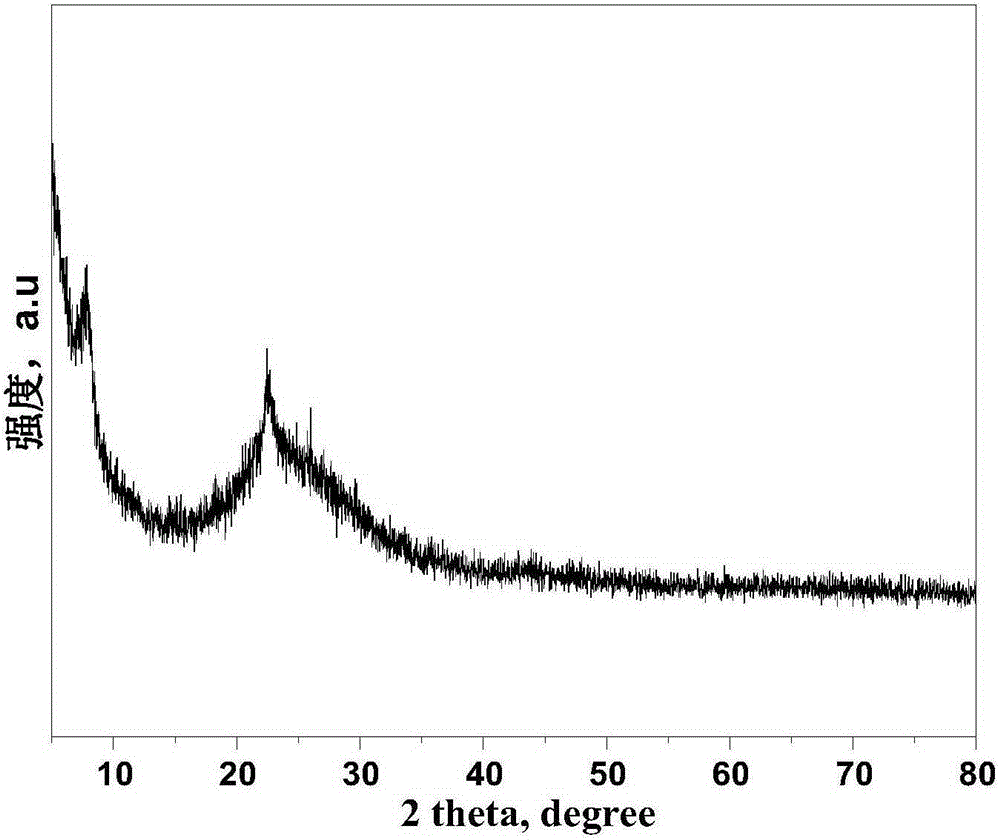

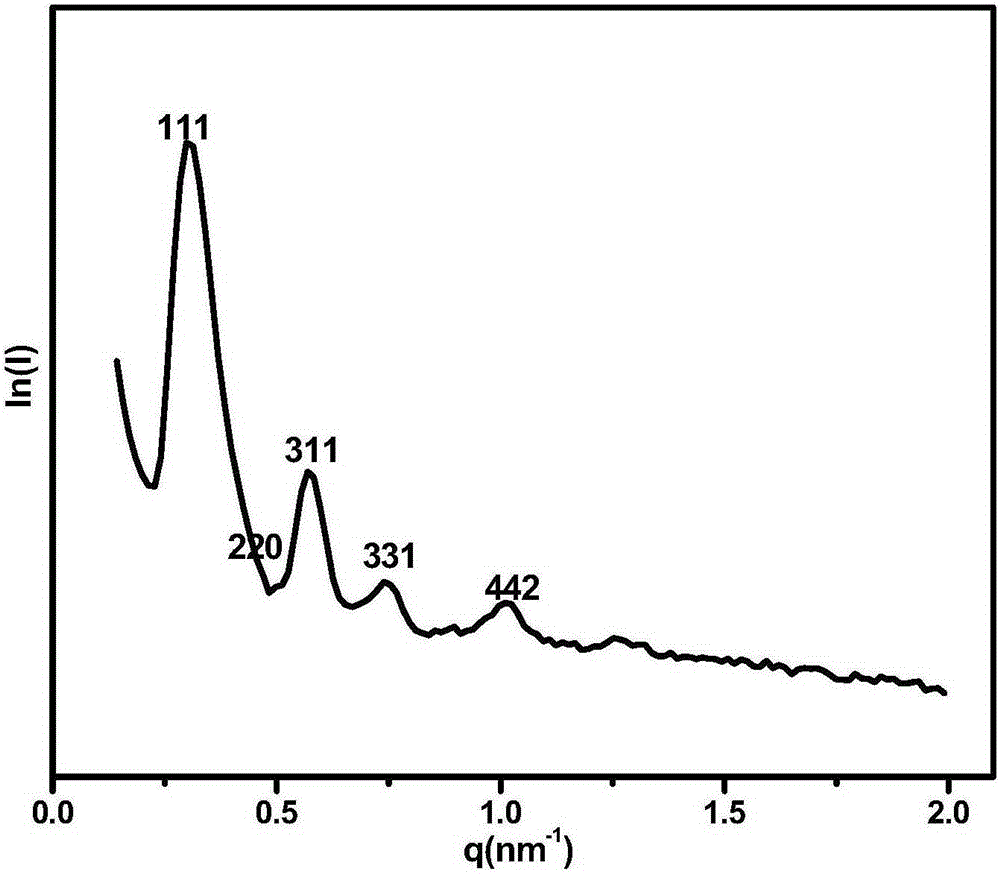

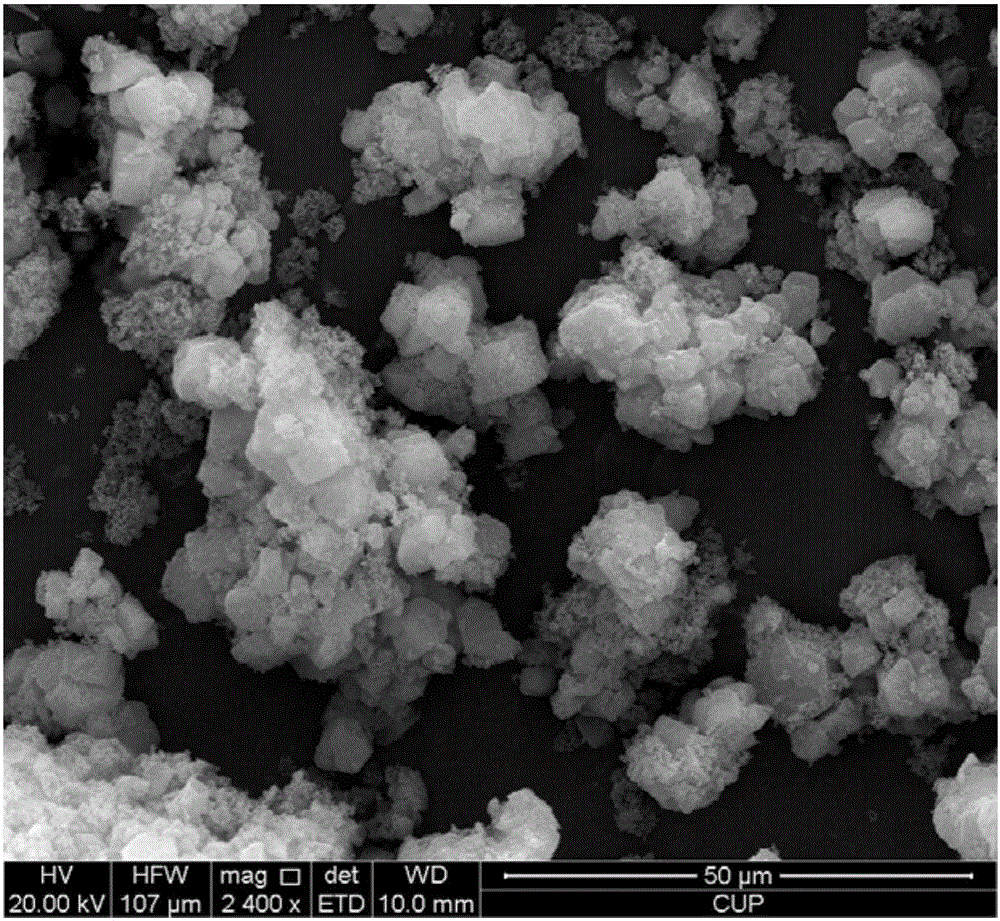

[0054] The present embodiment provides a kind of Beta-FDU-12 composite molecular sieve, and its preparation process comprises the following steps:

[0055] 1. Preparation of Beta zeolite precursor emulsion

[0056] Prepare raw materials, the amount of TEOS is SiO 2 Gauge, NaAlO 2 The dosage is Al 2 o 3 In terms of, the amount of NaOH is Na 2 In terms of O, the molar ratio of the amount of each raw material is SiO 2 :Al 2 o 3 : Na 2 O:TEAOH:H 2 O=60:1.0:1.4:14:360. TEAOH directly uses a solution with a mass percent content of 25 wt%, and obtains the amount of the solution after conversion. The specific preparation process is:

[0057] Step 1: take a part of TEAOH (25wt%) and record it as solution (1), add TEOS into solution (1), and stir evenly for a period of time to form a slightly opaque sol, which is recorded as solution (2);

[0058] Step 2: NaOH, NaAlO 2 Mix with the remaining TEAOH (25wt%), then add deionized water and stir until dissolved, which is referred...

Embodiment 2

[0069]This embodiment provides a hydrodesulfurization catalyst, and the preparation method of the catalyst comprises the following steps:

[0070] 1. Preparation of H-type Beta-FDU-12 composite molecular sieve carrier after ion exchange treatment

[0071] The Beta-FDU-12 composite molecular sieve carrier that embodiment 1 makes and the NH of 1mol / L 4 Cl solution corresponds to 10ml NH per 1g carrier 4 Proportion of Cl solution: Stir for 2 hours in a water bath at 80°C for ammonium exchange, filter, wash, and dry, and then perform the second ammonium exchange in the same steps to obtain the H-type Beta-FDU-12 composite molecular sieve carrier.

[0072] 2. Preparation of mixed carrier

[0073] The above-mentioned H-type Beta-FDU-12 composite molecular sieve carrier and γ-Al were mixed by mechanical mixing method. 2 o 3 Beta-FDU-12-γ-Al was prepared by mixing at a mass ratio of 1:4 2 o 3 Mixed carrier (denoted as ABF).

[0074] 3. Preparation of Hydrodesulfurization Cataly...

Embodiment 3

[0079] This embodiment provides a hydrodesulfurization catalyst treated with an organic complexing agent, and the preparation method of the catalyst comprises the following steps:

[0080] 1. Dissolve 1.6g of CA in 10.6g of ammonia solution with a pH of 9 to obtain solution a;

[0081] 2. Use solution a to impregnate the Cat-ABF prepared in Example 2, and then dry it at 120° C. for 4 hours. The treated catalyst is designated as Cat-L1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com