Method of preparing biomass high specific surface micro-pore carbon material

A high specific surface area, biomass material technology, applied in the field of microporous carbon material preparation, can solve the problems of microporous carbon material failing to achieve the application effect, low specific surface area of microporous carbon material, wide distribution of activated carbon pores, etc. Effect of wood and high quality coal, low price, narrow pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

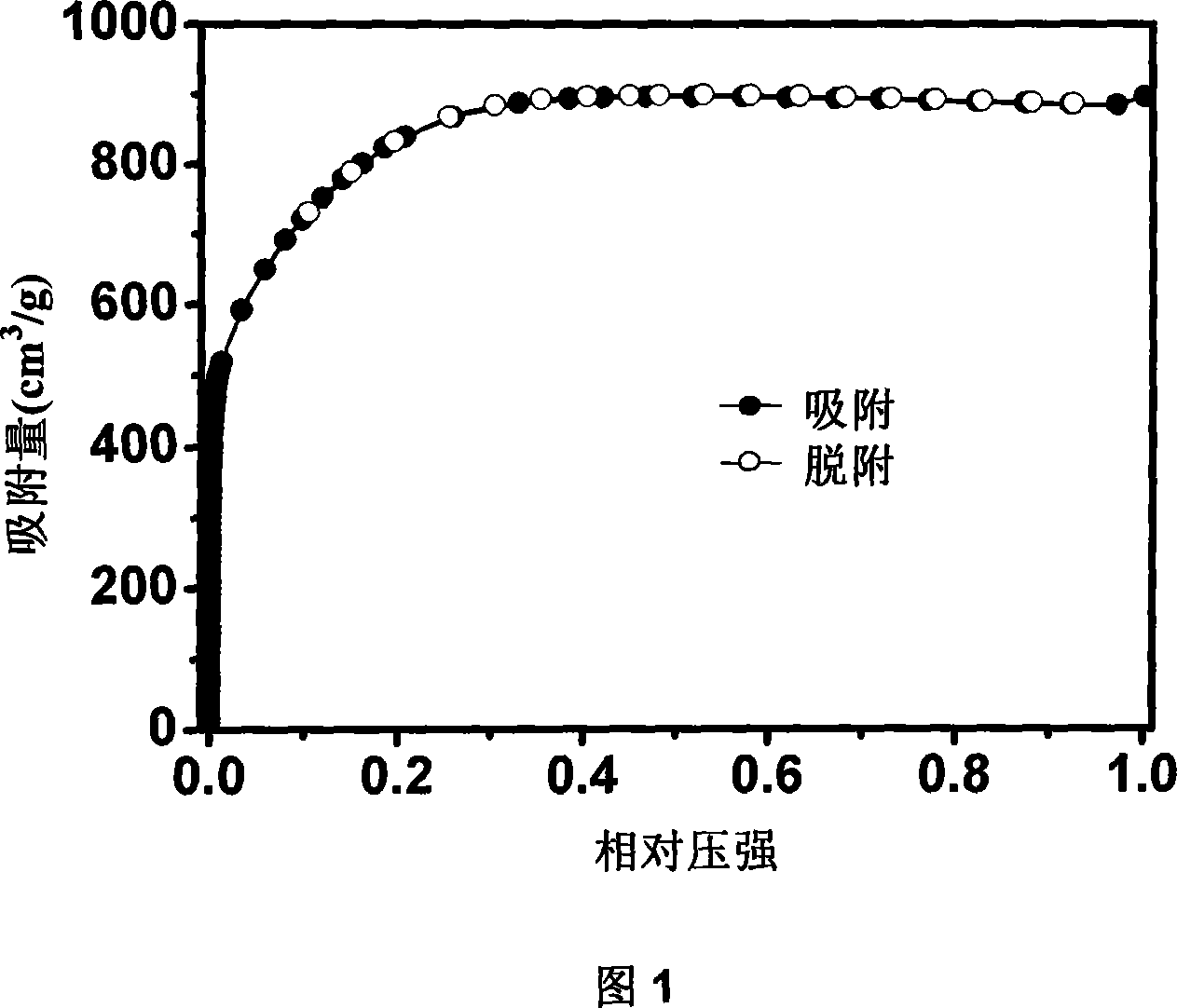

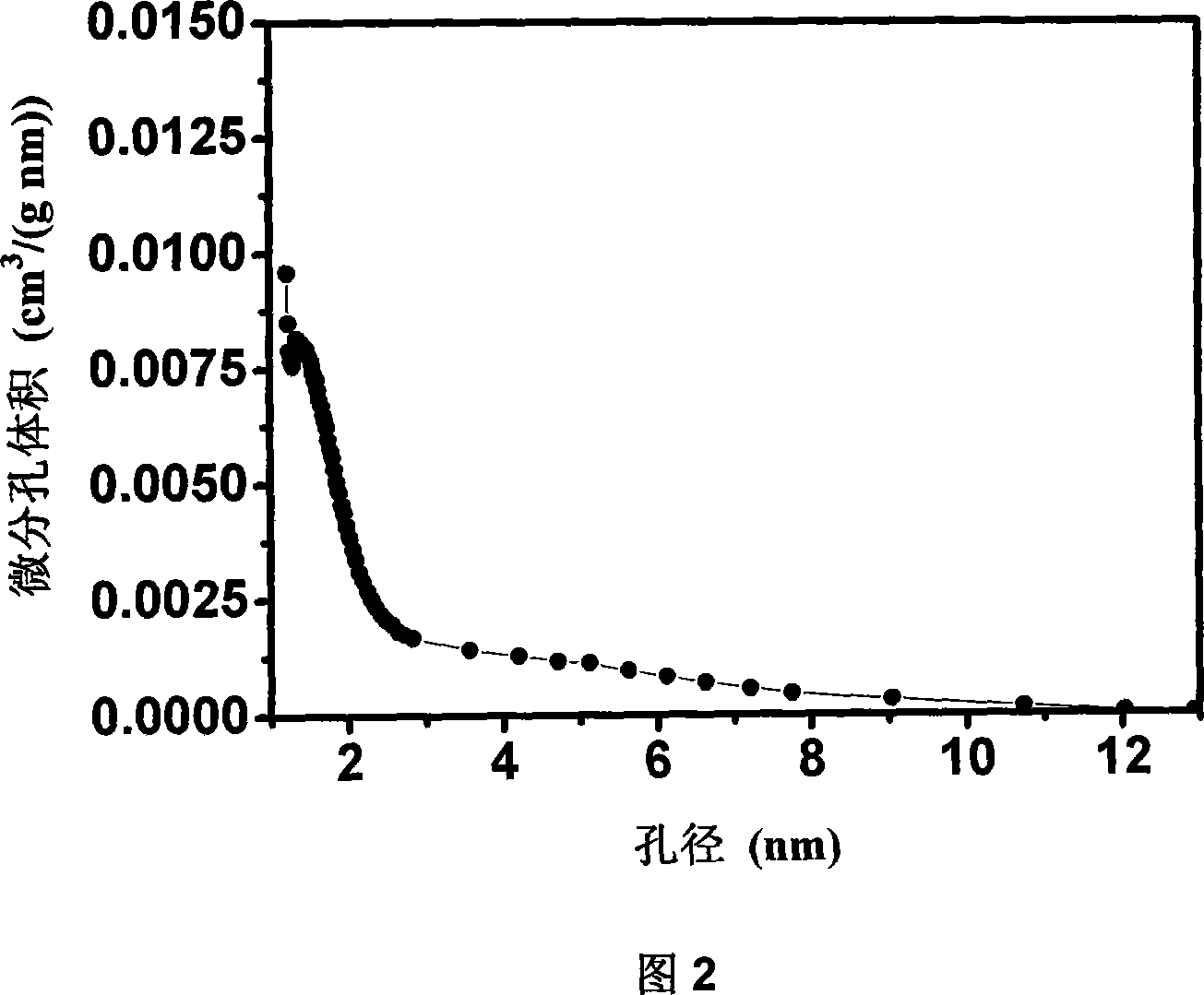

Embodiment 1

[0020] Wash the corn stalks, dry them, and cut them into 1.5 cm long pieces. Under the protection of nitrogen, carbonize at 400° C. for 3 hours to obtain carbonized products and by-product tar. The obtained charred product was immersed in 1 mol / L KOH solution (25 ml solution per gram of charred product) for 24 hours. Activate the carbonized product taken out at 750°C for 2 hours, then wash it with deionized water until pH = 7, then soak it with dilute hydrochloric acid (0.1mol / L) for 5 hours, then wash the product with deionized water until The pH of the washing solution is 7, and the microporous carbon material is obtained after drying at 100°C for 3 hours. The specific surface area of the material is 880m 2 / g, the pore size is mainly 1.4nm.

Embodiment 2

[0022] The experimental method is the same as in Example 1, except that the concentration of the activator KOH solution is changed to 2mol / L, and a microporous carbon material is also obtained, and the specific surface area of the material is 1300m 2 / g, the pore size is mainly 1.4nm.

Embodiment 3

[0024] The experimental method is the same as in Example 1, except that the concentration of the activator KOH solution is changed to 3mol / L, and the microporous carbon material is also obtained, and the specific surface area of the material is 1412m 2 / g, the pore size is mainly 1.4nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com