Method for preparing mixed crystal type titanium dioxide nano-powder and product thereof

A technology of titanium dioxide and nanopowder, which is applied in the field of photocatalytic materials, can solve the problems of difficulty in precise control of the amount or time of addition, difficulty in adapting to large-scale batch production requirements, low product quality stability, etc., and achieve excellent photocatalytic degradation ability , Small grain size, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

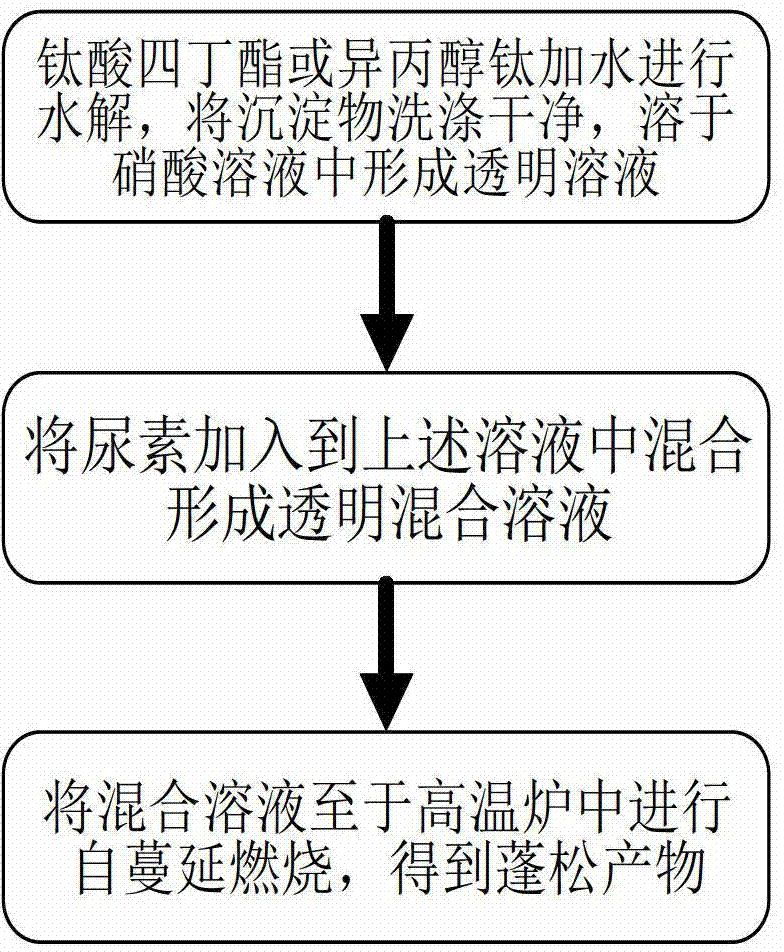

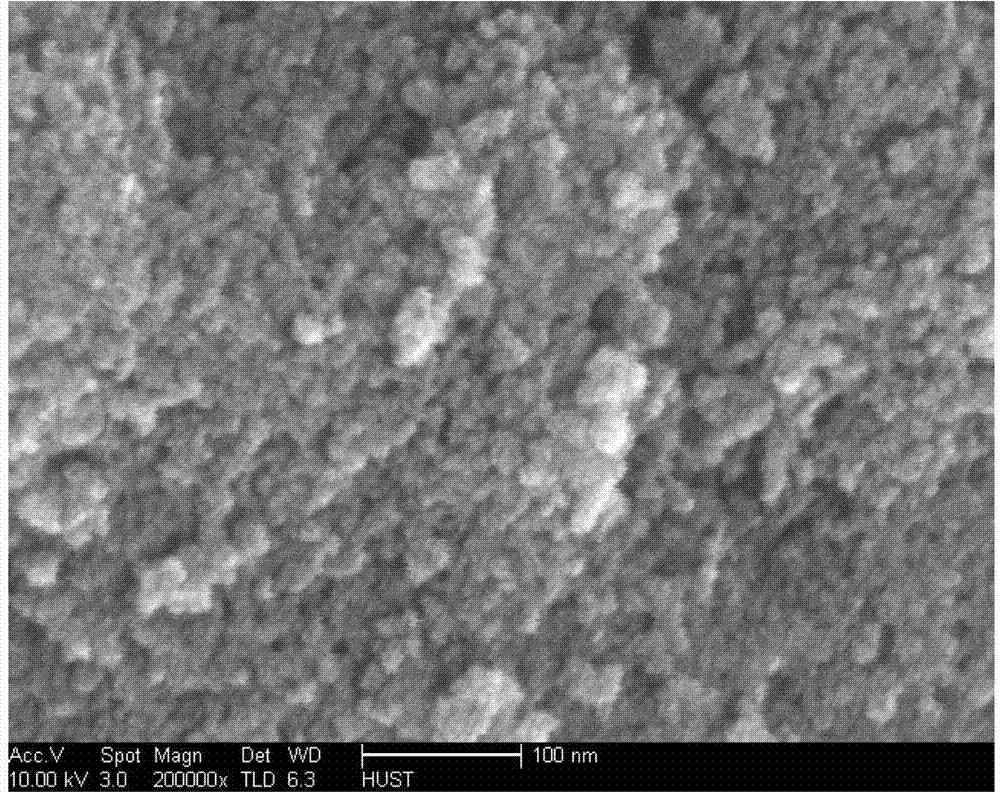

Embodiment 1

[0036]Weigh 10.20 g of tetrabutyl titanate, add an appropriate amount of deionized water to completely hydrolyze tetrabutyl titanate to obtain a white precipitate, separate the white precipitate and wash it with deionized water, and then add 30 mL of deionized After soaking in water, slowly add about 20mL of concentrated nitric acid dropwise to it while stirring, fully stir to dissolve the precipitate completely, and obtain a clear and transparent solution; then add urea and appropriate Deionized water (in this example, 0.81g of urea and an appropriate amount of deionized water were specifically added), and after magnetic stirring, a 100ml clear and transparent mixed solution was formed; the above mixed solution was placed in a high-temperature furnace at 350°C, and the solution After evaporation, boiling and foaming, a violent combustion reaction occurs, and a fluffy powder is obtained after the combustion reaction is completed. The powder was ground with a mortar to obtain 1...

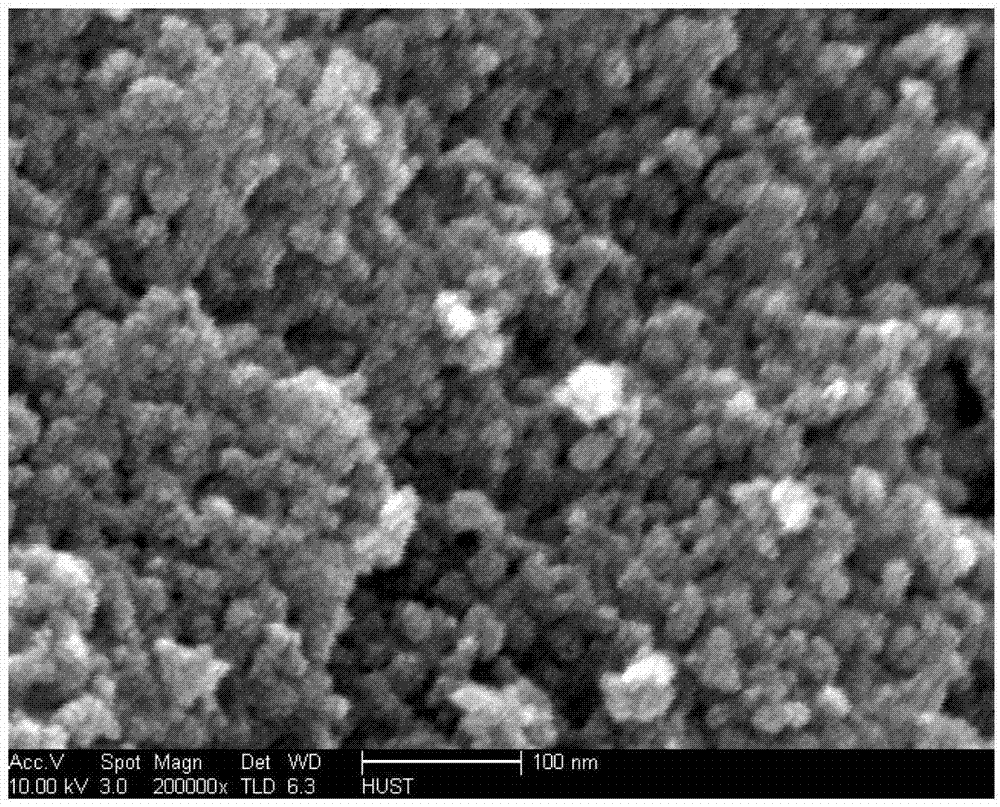

Embodiment 2

[0039] Weigh 8.53g of titanium isopropoxide, add an appropriate amount of deionized water to completely hydrolyze titanium isopropoxide to obtain a white precipitate, separate the white precipitate and wash it with deionized water, and then add 30mL of deionized water to the precipitate , while stirring, slowly add about 20mL of concentrated nitric acid dropwise to it, stir fully to dissolve the precipitate completely, and obtain a clear and transparent solution; then add urea and appropriate deionized water (in this example, 4.50g of urea and an appropriate amount of deionized water were specifically added), and after magnetic stirring, a 100ml clear and transparent mixed solution was formed; the above mixed solution was placed in a high-temperature furnace at 500°C, and the solution was evaporated , After boiling and foaming, a violent combustion reaction occurs, and fluffy powder is obtained after the combustion reaction is completed. The powder was ground with a mortar to ...

Embodiment 3

[0042] Weigh 10.2 g of tetrabutyl titanate, add an appropriate amount of deionized water to completely hydrolyze tetrabutyl titanate to obtain a white precipitate, separate the white precipitate and wash it with deionized water, and then add 30 mL of deionized After soaking in water, slowly add about 20mL of concentrated nitric acid dropwise to it while stirring, stir fully to dissolve the precipitate completely, and obtain a clear and transparent solution; then add glycine and Appropriate amount of deionized water (in this example, 2.50 g of glycine and appropriate amount of deionized water were specifically added), and after magnetic stirring, 100 ml of clear and transparent mixed solution was formed; the above mixed solution was placed in a high-temperature furnace at 600 ° C, and the solution After evaporation, boiling and foaming, a violent combustion reaction occurs, and a fluffy powder is obtained after the combustion reaction is completed. The powder was ground with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com