Oxygen-deficient titanium dioxide material compounded with hydroxylated carbon nitride and preparation method thereof

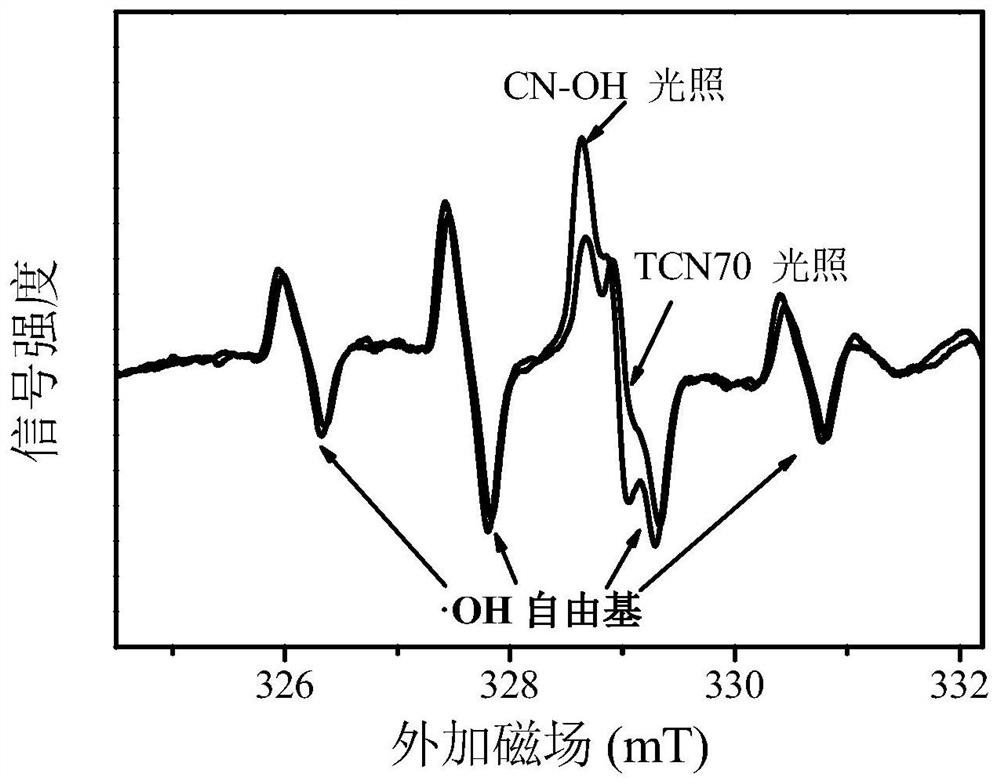

A technology for compounding hydroxylated carbon nitride and hydroxylated carbon nitride is applied in the field of photocatalysis, which can solve the problems of low quantum efficiency and achieve the effects of improving quantum efficiency, good stability and enhancing separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the oxygen-deficient titanium dioxide material composited with hydroxylated carbon nitride of the present invention comprises the following steps:

[0031] (1) Surface hydroxylation g-C 3 N 4 preparation of

[0032] Weigh 1.5g of melamine, 7.5g of potassium chloride and 0.1g of sodium hydroxide, mix them well and place them in a corundum crucible, cover them and place them in a muffle furnace, and calcinate at 550°C for 4h with a heating rate of 2.5°C / min . After cooling to room temperature naturally, take it out and grind it. Disperse the obtained powder in 100mL deionized water, stir for 6 hours, filter with suction, wash and dry at 80°C, and cool to obtain the surface hydroxylated g-C 3 N 4 sample. Samples are labeled CN-OH.

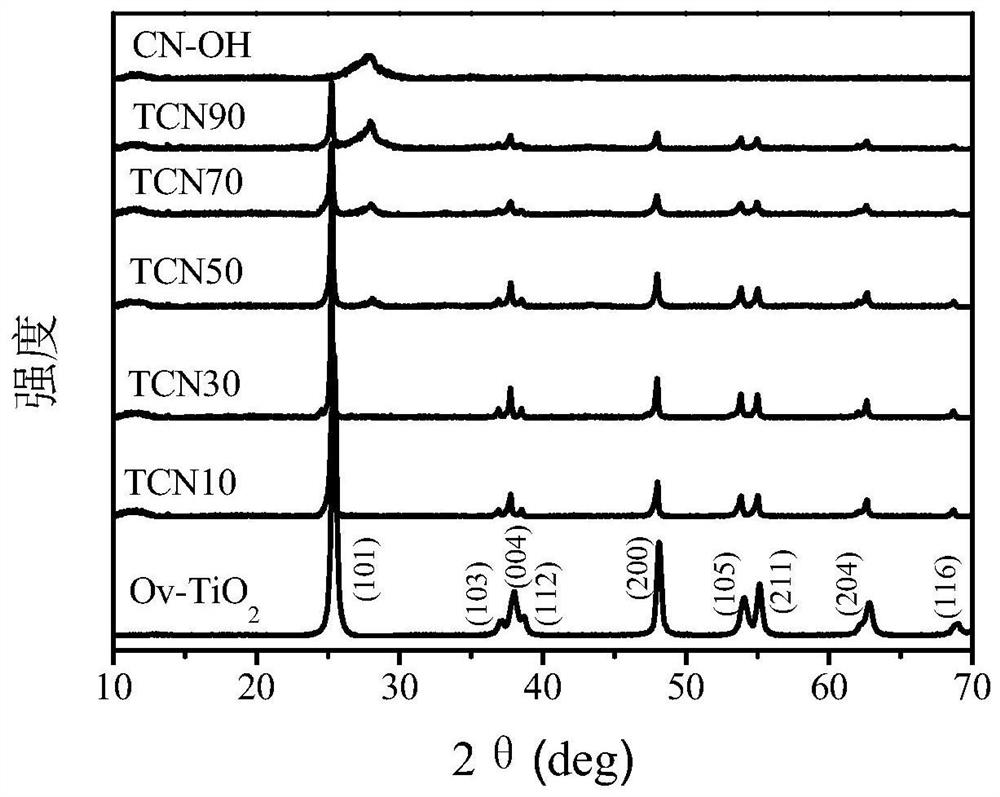

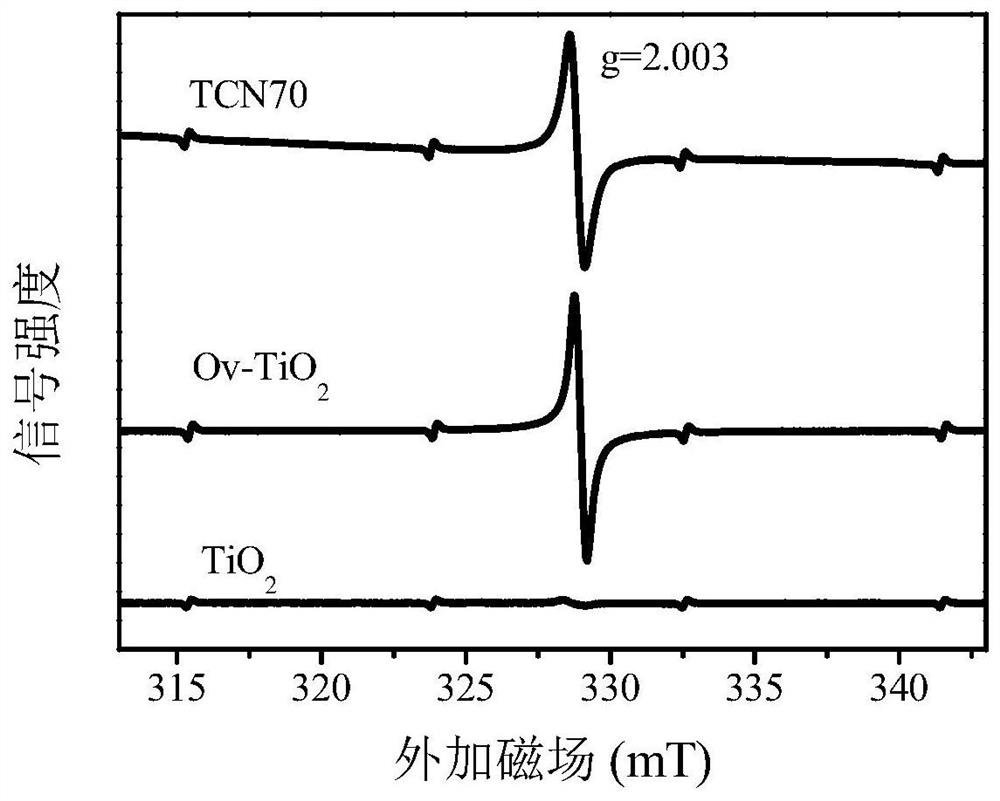

[0033] (2) CN-OH / oxygen-deficient TiO 2 Preparation of composite materials

[0034] Add 3 mL of titanium isopropoxide into 6 mL of absolute ethanol, mix well, and slowly add it dropwise into 40 mL of deionized...

Embodiment 2

[0036] The preparation method of the oxygen-deficient titanium dioxide material composited with hydroxylated carbon nitride of the present invention comprises the following steps:

[0037] (1) Surface hydroxylation g-C 3 N 4 preparation of

[0038] Weigh 1.5g of melamine, 7.5g of potassium chloride and 0.1g of sodium hydroxide, mix them thoroughly and place them in a corundum crucible, cover them and place them in a muffle furnace, and calcinate at 500°C for 5h with a heating rate of 3°C / min . After cooling to room temperature naturally, take it out and grind it. Disperse the obtained powder in 100mL deionized water, stir for 6 hours, filter with suction, wash and dry at 80°C, and cool to obtain the surface hydroxylated g-C 3 N 4 sample. Samples are labeled CN-OH.

[0039] (2) CN-OH / oxygen-deficient TiO 2 Preparation of composite materials

[0040] Add 3 mL of titanium isopropoxide into 6 mL of absolute ethanol, mix well, and slowly add it dropwise into 40 mL of deion...

Embodiment 3

[0042] The preparation method of the oxygen-deficient titanium dioxide material composited with hydroxylated carbon nitride of the present invention comprises the following steps:

[0043] (1) Surface hydroxylation g-C 3 N 4 preparation of

[0044] Weigh 1.5g of melamine, 7.5g of potassium chloride and 0.1g of sodium hydroxide, mix them well, place them in a corundum crucible, cover them and put them in a muffle furnace, and calcinate at 600°C for 2h, with a heating rate of 2°C / min . After cooling to room temperature naturally, take it out and grind it. Disperse the obtained powder in 100mL deionized water, stir for 6 hours, filter with suction, wash and dry at 80°C, and cool to obtain the surface hydroxylated g-C 3 N 4 sample. Samples are labeled CN-OH.

[0045] (2) CN-OH / oxygen-deficient TiO 2 Preparation of composite materials

[0046] Add 3 mL of titanium isopropoxide into 6 mL of absolute ethanol, mix well, and slowly add it dropwise into 40 mL of deionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com