Preparation method of visible light catalyst of surface nitrogen modified titanium dioxide nano-particles based on ALD technology

A technology of titanium dioxide and nanoparticles, which is applied in the field of preparation of new nano-functional materials and photocatalysis, can solve problems such as unsatisfactory nitrogen doping effects, and achieve the effects of enhanced visible light catalytic performance, improved utilization rate, and improved degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Using commercial titanium dioxide powder (P25) as a carrier, it was directly transferred into the ALD reaction chamber through the powder sample tank, and the surface was coated with TiN deposition for 20, 50 and 100 cycles by plasma-enhanced atomic layer deposition (PEALD). The specific deposition parameters are as follows: the growth temperature is 360 o C; using titanium tetrachloride (TiCl 4 ) and ammonia plasma as titanium source and nitrogen source, respectively; 150 sccm of high-purity nitrogen and 50 sccm of high-purity argon were used as carrier gases; the growth cycle parameters were 0.1s TiCl 4 -4s N 2 -21.5s ammonia plasma -6s N 2 Cleaning; the flow rate of ammonia gas is 150 sccm, and the plasma power is 2500 W.

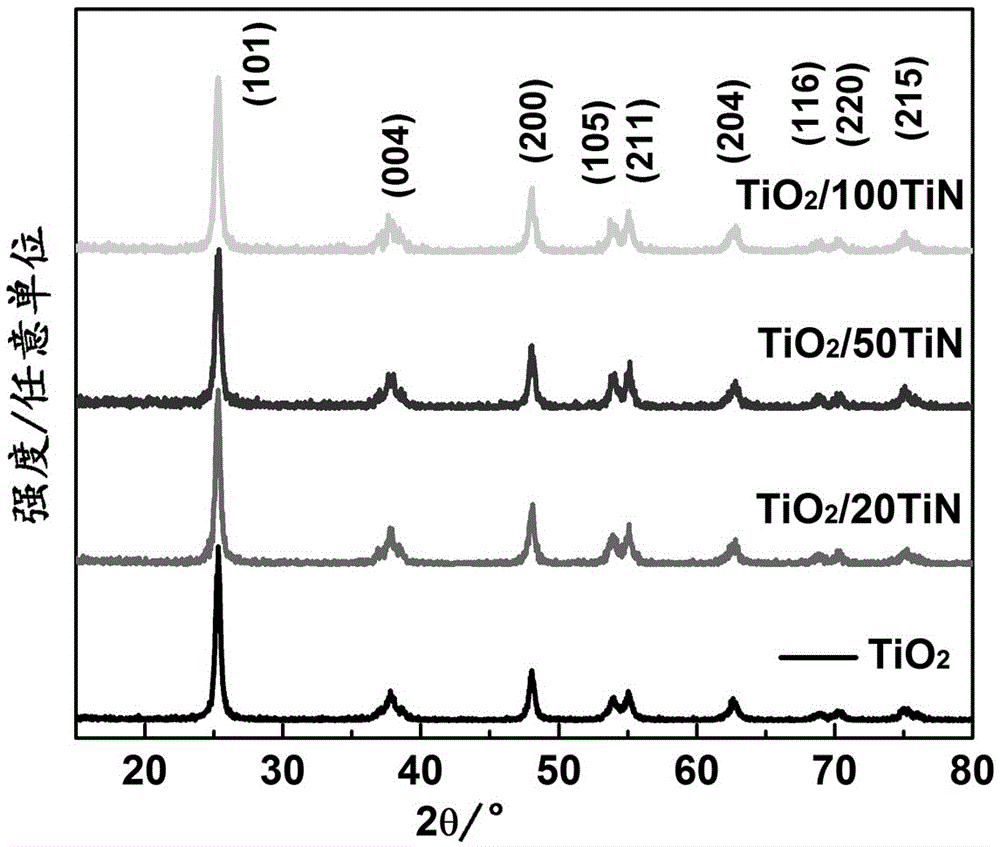

[0027] figure 1 The XRD patterns of the P25 powder and the P25 powder deposited with different cycles of PEALD on the surface, it can be seen that all samples show similar diffraction peaks, corresponding to the anatase phase of titanium dioxi...

Embodiment 2

[0030] Using commercial titanium dioxide powder (P25) as a support, plasma-enhanced atomic layer deposition (PEALD) was used at 360 o50 cycles of TiN were deposited on the P25 surface at C. Titanium tetrachloride and ammonia plasma are used as titanium source and nitrogen source, and the carrier gas is 150 sccm of high-purity nitrogen and 50 sccm of high-purity argon, respectively; the growth cycle parameter is 0.1s TiCl 4 -4sN 2 -21.5s ammonia plasma -6sN 2 Cleaning; the flow rate of ammonia gas is 150 sccm, and the plasma power is 2500 W.

[0031] Use the above-mentioned surface-modified P25 powder to degrade 4 mg / L methyl orange solution, using 100 mg P25 powder per 100 mL methyl orange solution. Catalyzed under visible light for 2 h, the degradation rate of methyl orange was measured, and then the solution was centrifuged to recover P25 powder. o C annealed for two hours to remove methyl orange adsorbed on the catalyst surface, and then photocatalytically degrade methy...

Embodiment 3

[0033] Using commercial titanium dioxide powder (P25) as a support, plasma-enhanced atomic layer deposition (PEALD) was used at 360 o 50 cycles of TiN were deposited on the P25 surface at C. In order to enhance the wrapping performance of TiN on titanium dioxide particles, the pulse time of titanium tetrachloride was extended to 2s, and other parameters were as in Example 1.

[0034] Use the above-mentioned surface-modified P25 powder to degrade 4 mg / L of methyl orange solution, and use 100 mg of P25 powder per 100 mL of methyl orange solution. The time curve of this P25 sample degrading methyl orange under visible light is as follows Figure 7 shown. It can be found that the extended TiCl 4 After the pulse time, the catalytic effect of the surface N-modified P25 powder on methyl orange was greatly improved, and the photocatalytic degradation rate was as high as 94% in 2 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com