Nonmetal doped titanium-based film electrode as well as preparation method and application thereof

A thin-film electrode and non-metallic technology, which is applied in the field of photoelectric catalysis of inorganic non-metallic materials, to achieve high photocatalytic efficiency, simple and easy-to-operate method, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

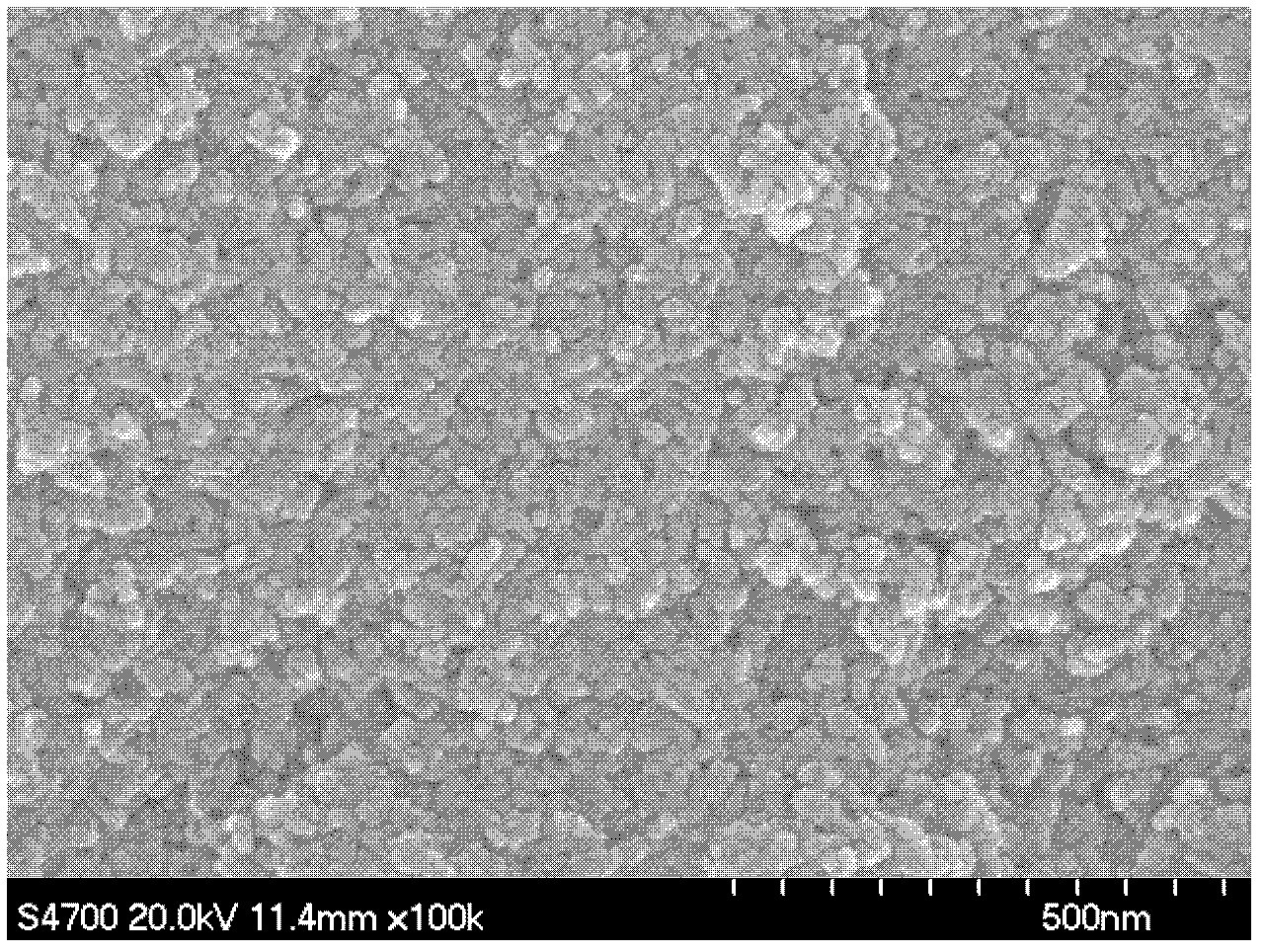

[0025] 1) Carbon-doped TiO 2 Preparation of particles: Ultrasonic mixing of glucose and titanium isopropoxide at a molar ratio of carbon to titanium of 0.05:1, under air conditions, the resulting mixed solution was kept stirring in a water bath at 30°C for 48 hours until the mixture became a powder state. Then put the powder in a muffle furnace and bake it at 400°C for 4 hours to get carbon-doped TiO 2 particles;

[0026] 2) TiO 2 Preparation of nanocrystals: At a stirring speed of 500 rpm, drop 4 mL of acetic acid into 40 mL of titanium isopropoxide, and continue stirring for 20 minutes, then add water at a uniform speed and heat to 80° C., and continue stirring for 30 minutes. Add nitric acid to adjust the pH value to 3, and then heat at 180°C for 12 hours to obtain TiO 2 Nanocrystalline milky liquid, in which TiO 2 The solid content is 20%;

[0027] 3) Preparation of carbon-doped titanium-based thin film electrodes: 0.5g carbon-doped TiO 2 Granules, 0.02g polyethylene...

Embodiment 2

[0030] 1) Iodine doped TiO 2 Preparation of particles: Ultrasonic mixing of elemental iodine and titanium isopropoxide at a ratio of iodine to titanium molar ratio of 0.1:1, under air conditions, the resulting mixed solution was stirred continuously in a water bath at 30°C for 48 hours until the mixture became a powder state. After that, put the powder in a muffle furnace and bake it at 500°C for 3 hours to obtain iodine-doped TiO 2 particles;

[0031] 2) with embodiment 1 step 2)

[0032] 3) Preparation of iodine-doped titanium-based thin film electrode: 0.5g iodine-doped TiO 2Granules, 0.01g polyethylene glycol 20000 and 1g TiO 2 After the milky liquid of nanocrystals is mixed and ground and dispersed evenly, deionized water is added to adjust the concentration to obtain TiO 2 The total solids content of the slurry is 15%. The slurry was uniformly coated on the ITO conductive glass substrate by a scalpel scraping method and dried at room temperature, and then the film w...

Embodiment 3

[0034] 1) Chlorine-doped TiO 2 Preparation of particles: Ultrasonic mixing of potassium chloride and titanium isopropoxide according to the ratio of chlorine to titanium molar ratio of 0.15:1, the resulting mixed solution was in contact with air, kept stirring in a water bath at 50°C for 48 hours until the mixture became powder state. Then put the powder in a muffle furnace and bake it at 550°C for 2 hours to get chlorine-doped TiO 2 particles;

[0035] 2) with embodiment 1 step 2)

[0036] 3) Preparation of chlorine-doped titanium-based thin film electrode: 0.5g chlorine-doped TiO 2 Granules, 0.01g sodium cellulose and 1g TiO 2 After the milky liquid of nanocrystals is mixed and ground and dispersed evenly, deionized water is added to adjust the concentration to obtain TiO 2 The total solid content of the slurry is 20%. The slurry was uniformly coated on the ITO conductive glass substrate by a scalpel scraping method and dried at room temperature, and then the film was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com