Preparation and application of CNQDs (Carbon nitride quantum dots)-modified TiO2 photonic crystal catalyst

A quantum dot and carbon nitride technology, applied in physical/chemical process catalysts, air quality improvement, inorganic chemistry, etc., can solve the problems of inability to completely remove organic molecules, low utilization efficiency of sunlight, and low specific surface area of materials , to achieve the effect of promoting photocatalytic performance, enhancing the ability of photocatalytic degradation of organic pollutants, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

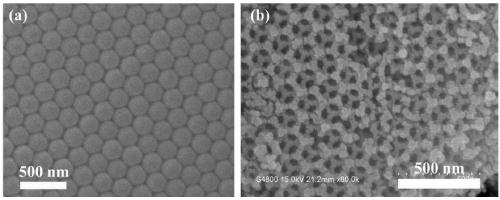

[0036] Preparation of polystyrene pellet template

[0037] Polystyrene pellets were prepared by emulsion polymerization. In a three-necked flask, sodium lauryl sulfate (0.45g), potassium persulfate (0.6g) were dissolved in a mixed solution of 132mL ethanol and 288mL water under a constant temperature of 25°C under magnetic stirring to form a colorless and transparent solution, N 2 Protect, heat the oil bath to 71°C, immediately add 36mL styrene with a syringe, cool to room temperature after refluxing for 19h, filter out large solidified substances with absorbent cotton, and obtain a milky white polystyrene emulsion. The emulsion was dried at 70° C. to obtain regularly arranged polystyrene sphere templates (with a particle size of 265 nm).

Embodiment

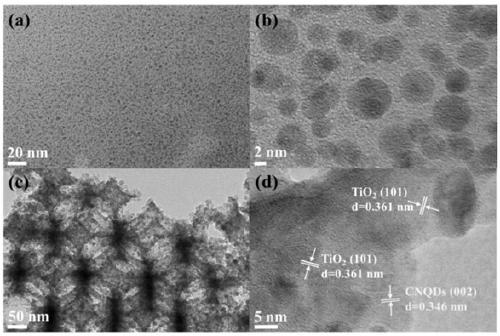

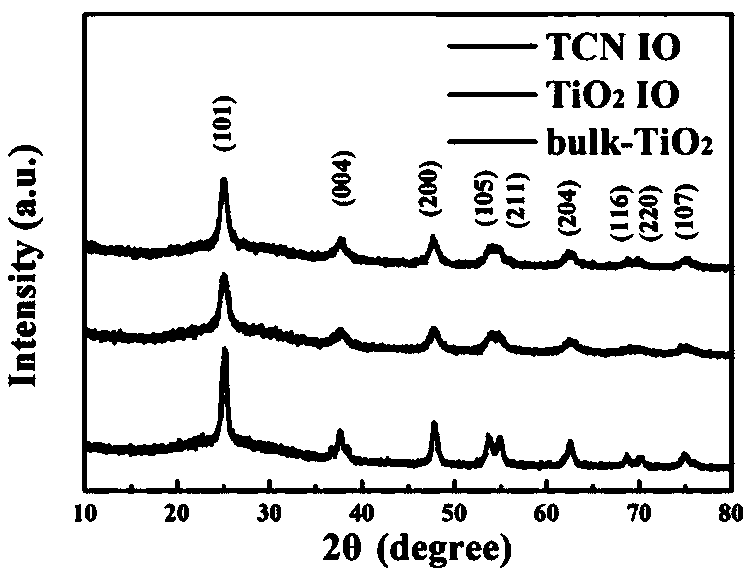

[0039] Carbon Nitride Quantum Dots Modified Inverse Opal TiO 2 Photocatalyst (TCN IO)

[0040] Preparation of CNQDs aqueous solution

[0041] Grind and mix 0.081g of sodium citrate and 0.101g of urea evenly and transfer them to the lining of a polytetrafluoroethylene reactor. Screw the stainless steel jacket tightly and seal it well, and keep it in an electric heating constant temperature blast drying oven at 180°C for 2h. After taking out the autoclave, let it cool naturally at room temperature, and ultrasonically wash the obtained brown solid three times with absolute ethanol, put it into a dialysis bag of MWCO3500 specification, and dialyze it in 20mL deionized water at room temperature for 24 hours to obtain light yellow carbon nitride quantum dots aqueous solution.

[0042] Add 1 mL of acetylacetone to 25 mL of ethanol and stir to dissolve, then add 5.6 mL of isopropyl titanate, stir for 2 minutes, then add 0.85 mL of concentrated hydrochloric acid and 4.6 mL of carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com