Recyclable and reusable organic dye photocatalyst and preparation method thereof

A photocatalyst and organic dye technology, applied in the field of organic dye photocatalyst and its preparation, can solve the problems of compound reduction, destruction, degradation rate of organic dyes, etc., and achieve stability guarantee, high degradation rate, and easy magnetic recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The embodiment of the present invention discloses a method for preparing an organic dye photocatalyst composite that is easy to recycle and can be used repeatedly, comprising the following steps:

[0032] a) mixing graphene oxide solution, isopropyl titanate, sulfuric acid and alcohol to obtain a mixed solution;

[0033] b) heating and reacting the mixed solution to obtain a graphene-titanium dioxide composite;

[0034] c) The graphene-titania composite, containing Fe 2+ and Fe 3+ solution with OH - The solutions are mixed, heated and reacted to obtain a photocatalyst composite.

[0035] Step a) is the process of preparing the mixed solution. The ratio of the graphene oxide solution, sulfuric acid, isopropyl titanate and alcohol is preferably 4~10mL: 40~100μL: 110~250μL: 20~200mL. The graphene oxide solution is preferably graphene oxide prepared by the hummer method, and the concentration of the graphene oxide solution is preferably 0.5 mg / mL. After the mixed solut...

Embodiment 1

[0045] a) Take 7mL of 0.5mg / mL graphene oxide prepared by the hummers method and add it to 65mL of absolute alcohol;

[0046] b) Dissolve 180 μL of isopropyl titanate and 70 μL of concentrated sulfuric acid in 5 mL of absolute alcohol to obtain a mixture, which is slowly poured into the mixture obtained in step a), and the temperature is raised to 80°C and kept for 12 hours, and then the product Put it in an autoclave and seal it, and react at 200°C for 12h;

[0047] c) Disperse the product obtained in step b) in 30mL deionized water, stir with nitrogen gas, add 3.95mgFeCl 2 ·H 2 O and 60mgFeCl 3 ·H 2 1.56mL of deionized water with O, stirred for 5h under nitrogen, sealed the container, then slowly injected 4.6mL of 1.5mol / L ammonia water with a syringe, and raised the temperature to 65°C in a sealed state for 2.5h;

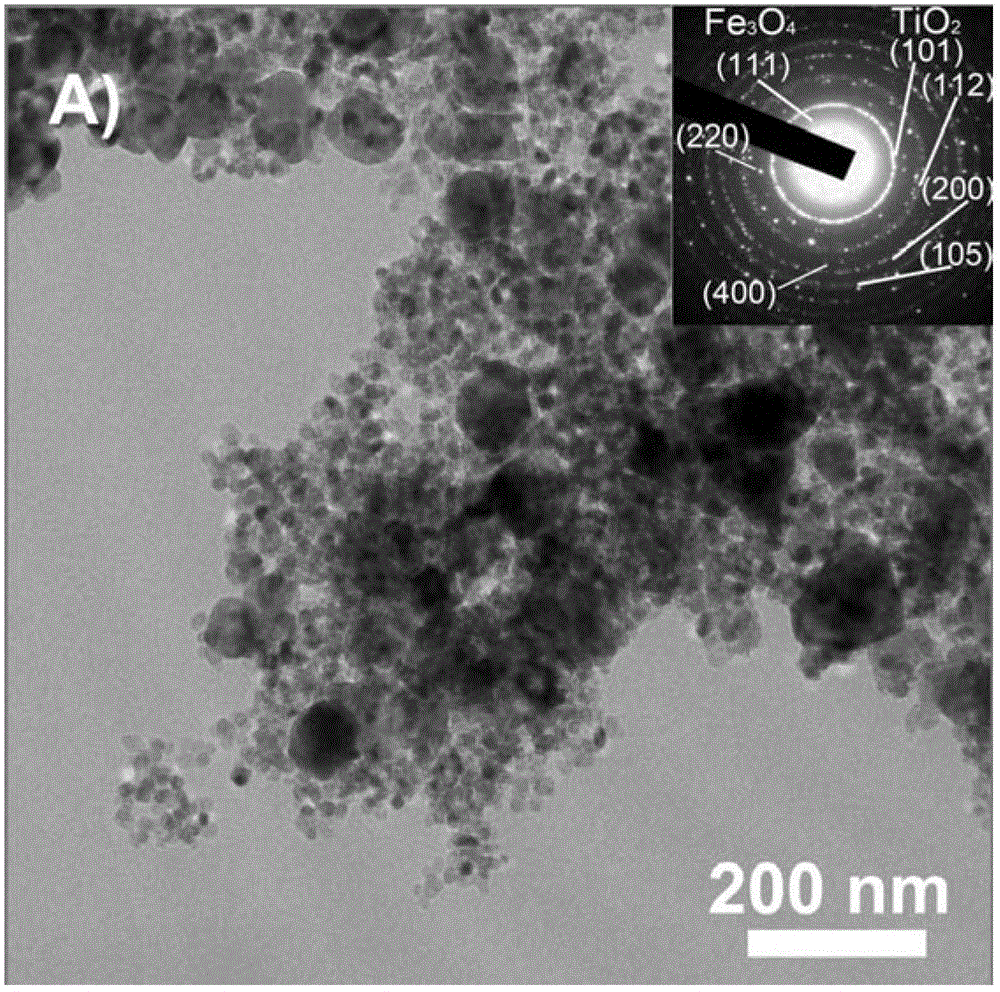

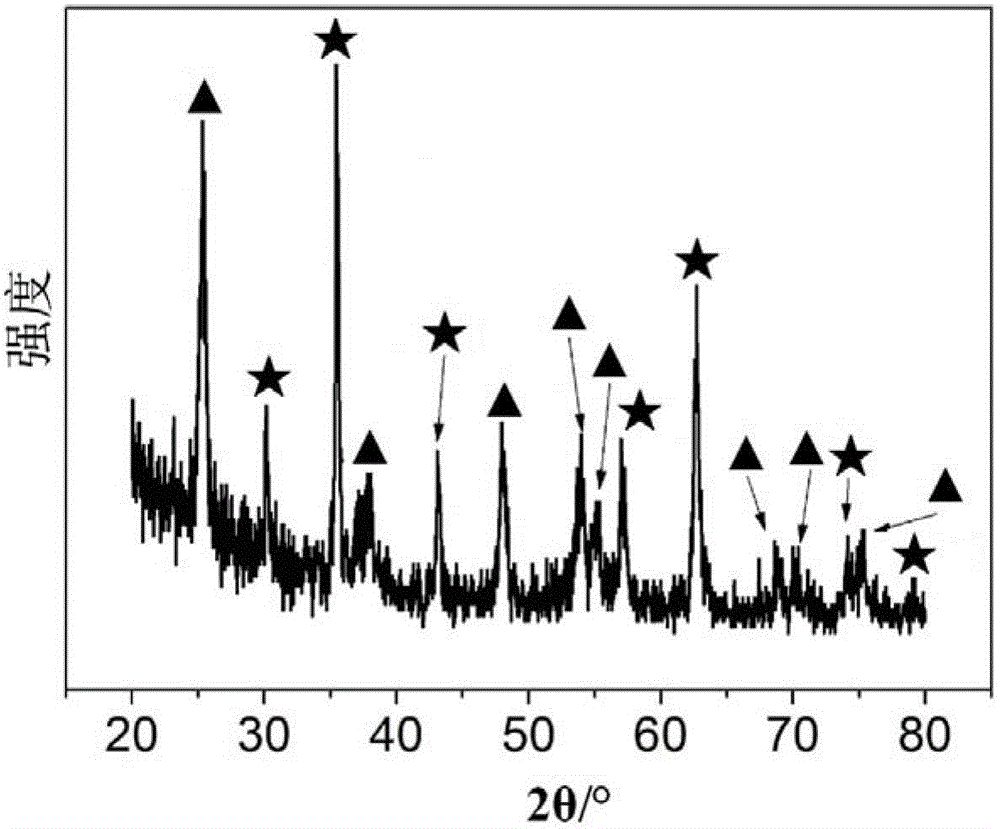

[0048] d) Wash the obtained product with deionized water, disperse the above product on a carbon-coated copper grid for electron microscope testing, and obta...

Embodiment 2

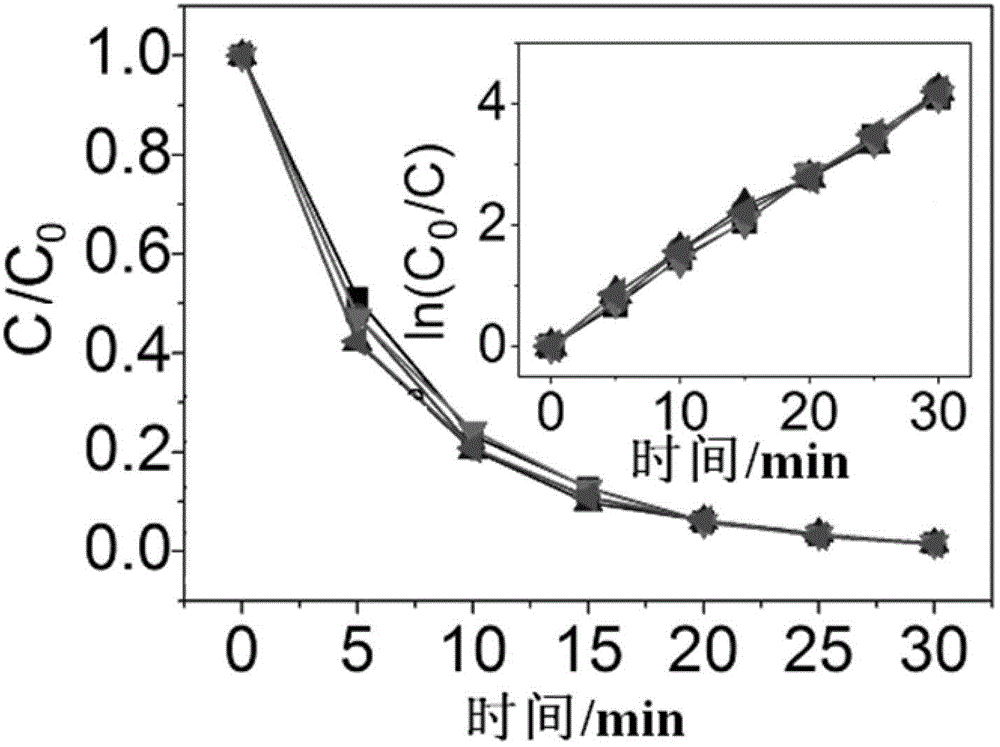

[0052] a) Soak the photocatalyst in the Rhodamine B solution for 12 hours to saturate the adsorption of Rhodamine B on its surface; recover the photocatalyst and disperse it in 71mL of deionized water;

[0053] b) The mixture in step a) is fully shaken to disperse the photocatalyst in deionized water evenly, take 100 μL of the photocatalyst mixture, and place it in a 5mL7.7×10 -6 In the Rhodamine B solution of mol / L, the pH value of Rhodamine B solution is 7.03;

[0054] c) Under the irradiation of Philip-TUV / 15W ultraviolet lamp, stir the mixture obtained in step b), and after degrading for 5 minutes, attract the photocatalyst to the side of the quartz bottle with a magnet, and take 2mL of the reaction solution to measure the absorption spectrum;

[0055] d) Repeat c) of this embodiment until the reaction solution is colorless, that is, Rhodamine B is completely degraded, and then the photocatalyst is recovered with a magnet;

[0056] e) Repeat step a) to step d) of this exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com