Magnetic nano functional material for extracting uranium from seawater, and preparation method thereof

A technology of magnetic nano and functional materials, applied in seawater treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of low adsorption capacity, easy agglomeration and sedimentation, and low stability, and achieve good and stable magnetic properties Durable, suitable for pH range, good effect of biological resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

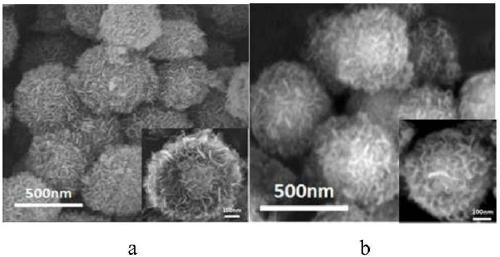

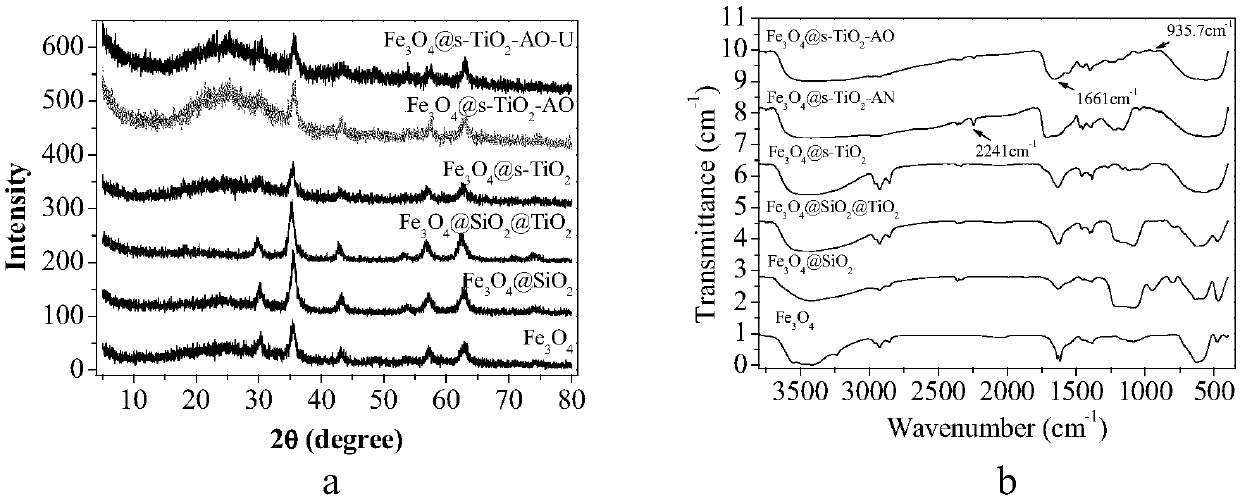

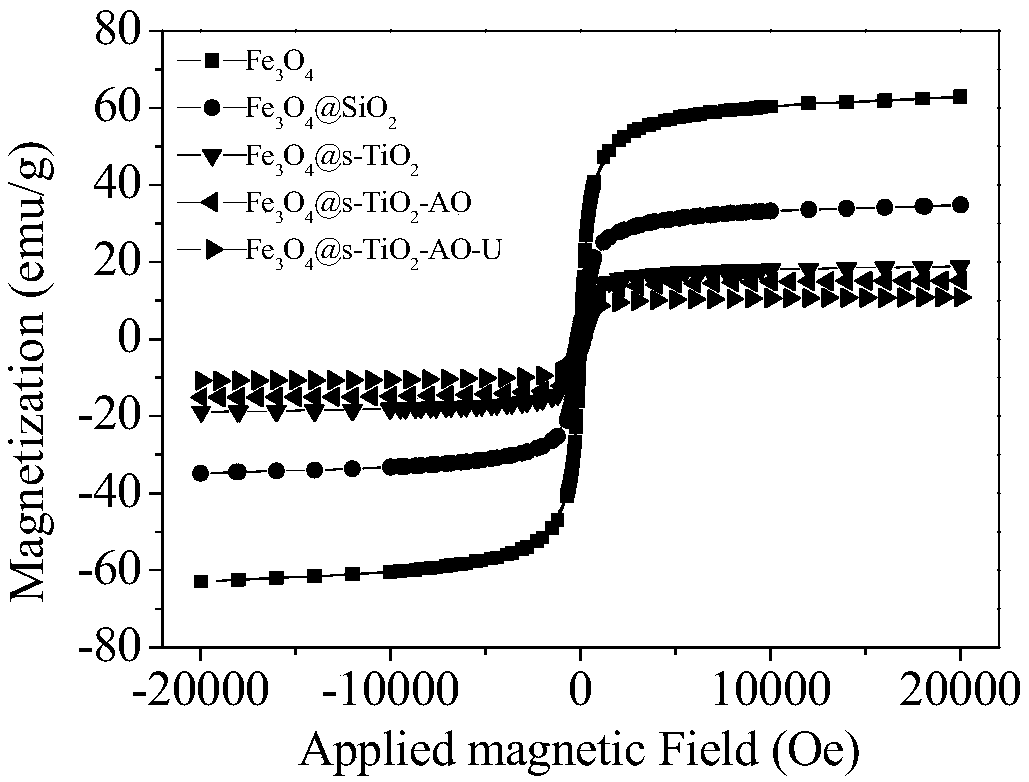

Image

Examples

Embodiment 1

[0036] A method for preparing a magnetic nano functional material for extracting uranium from seawater, comprising the following steps:

[0037] Step 1: Weigh ferric chloride hexahydrate and trisodium citrate dihydrate and dissolve them in ethylene glycol, then add anhydrous sodium acetate to it to control ferric chloride hexahydrate, trisodium citrate dihydrate and anhydrous sodium acetate The molar ratio is 3:1:16, heated and stirred to dissolve, refluxed at 70°C and stirred for 30-60 minutes, then transferred to a reaction kettle at 160-200°C for 8-12 hours, and naturally cooled to room temperature after the reaction , magnetically separated, washed, and dried to obtain black magnetic Fe 3 o 4 particles;

[0038] Step 2: Take Magnetic Fe 3 o 4 The particles are dispersed in the mixed solution A composed of ethanol, water and ammonia water, the volume ratio of ethanol, water and ammonia water in A is 75:5:4, the concentration of ammonia water is 28wt.%. 3 o 4 The mass ...

Embodiment 2

[0044] Fe 3 o 4 @s-TiO 2 - The preparation method of AO is the same as that of Example 1, wherein, in step 2, the volume ratio of ethanol, water and ammonia water in the mixed solution A is 85:5:4, and the concentration of ammonia water is 28wt.%; tetraethyl silicate The volume ratio with ethanol is 1:90. In Step 3, the volume ratio of ethanol to ammonia water in the mixed solution B is 250:1. In step 4, the reaction temperature of the high-temperature furnace in the autoclave was set at 150° C. for 24 hours. In step five, the addition of crosslinking agent N, N'-methylenebisacrylamide and potassium persulfate is 8% of the total mass of reactants in step five. The consumption of all the other materials is all the same as in Example 1.

Embodiment 3

[0046] Fe 3 o 4 @s-TiO 2 - The preparation method of AO is the same as that of Example 1, wherein, in step 2, the volume ratio of ethanol, water and ammonia water in the mixed solution A is 90:5:4, and the concentration of ammonia water is 28wt.%; tetraethyl silicate The volume ratio with ethanol is 1:180. In Step 3, the volume ratio of ethanol to ammonia water in the mixed solution B is 1000:3. In step 4, the reaction temperature of the high-temperature furnace in the autoclave was set at 200° C. for 16 hours. In step five, the addition of crosslinking agent N, N'-methylenebisacrylamide and potassium persulfate is 10% of the total mass of reactants in step five. The consumption of all the other materials is all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com