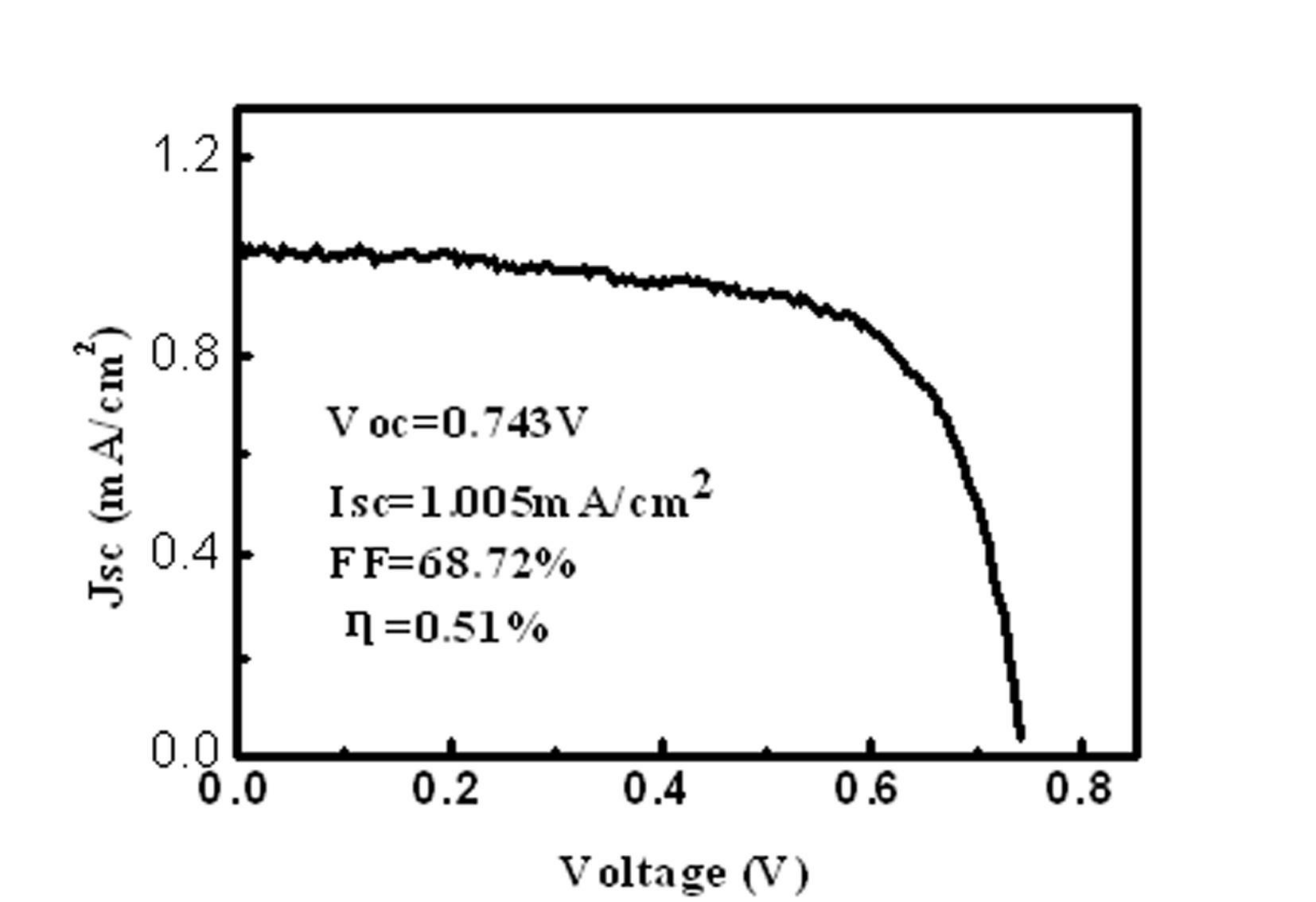

Method for preparing mesoporous titanium dioxide by template method and application of mesoporous titanium dioxide to preparation of dye-sensitized solar cells

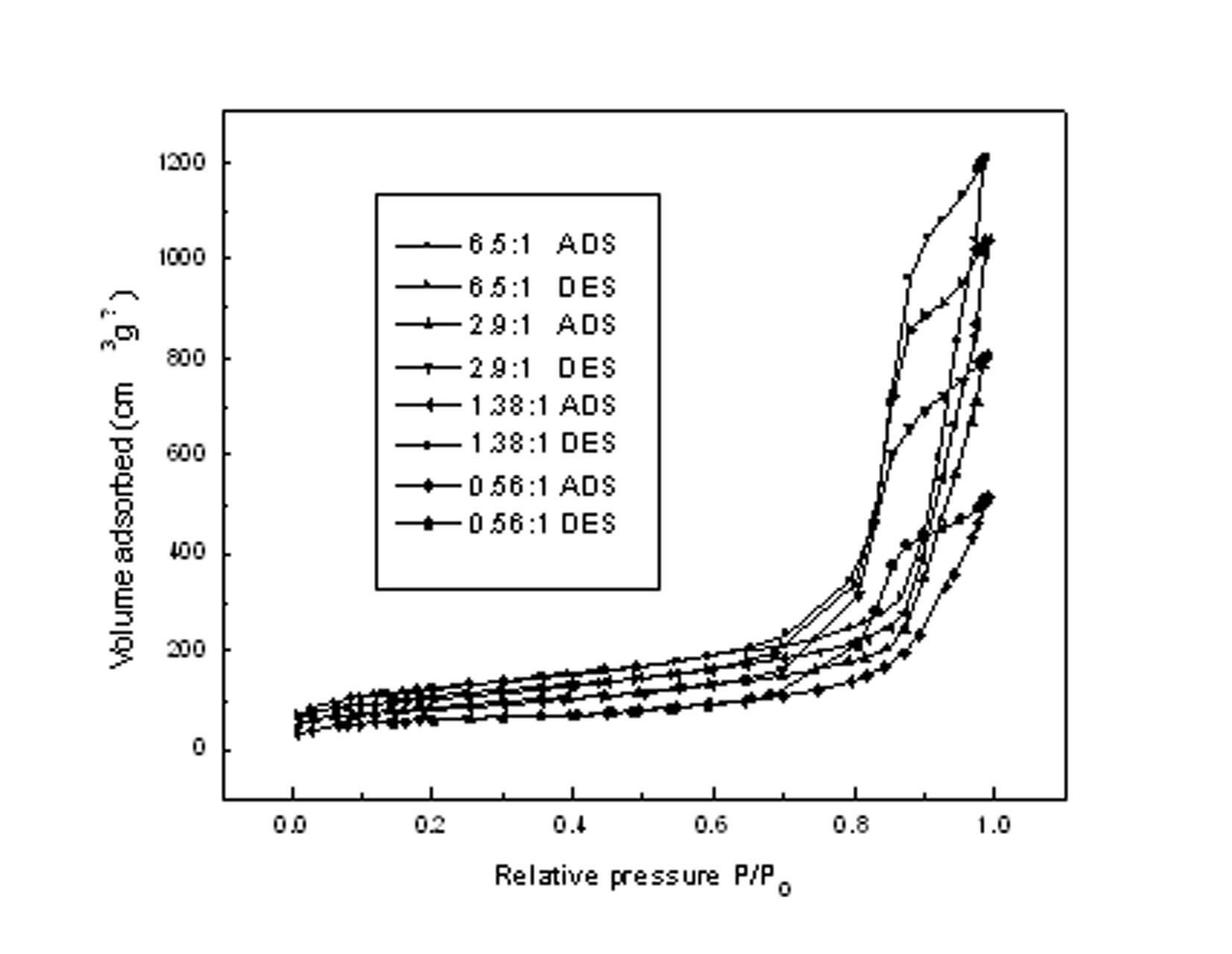

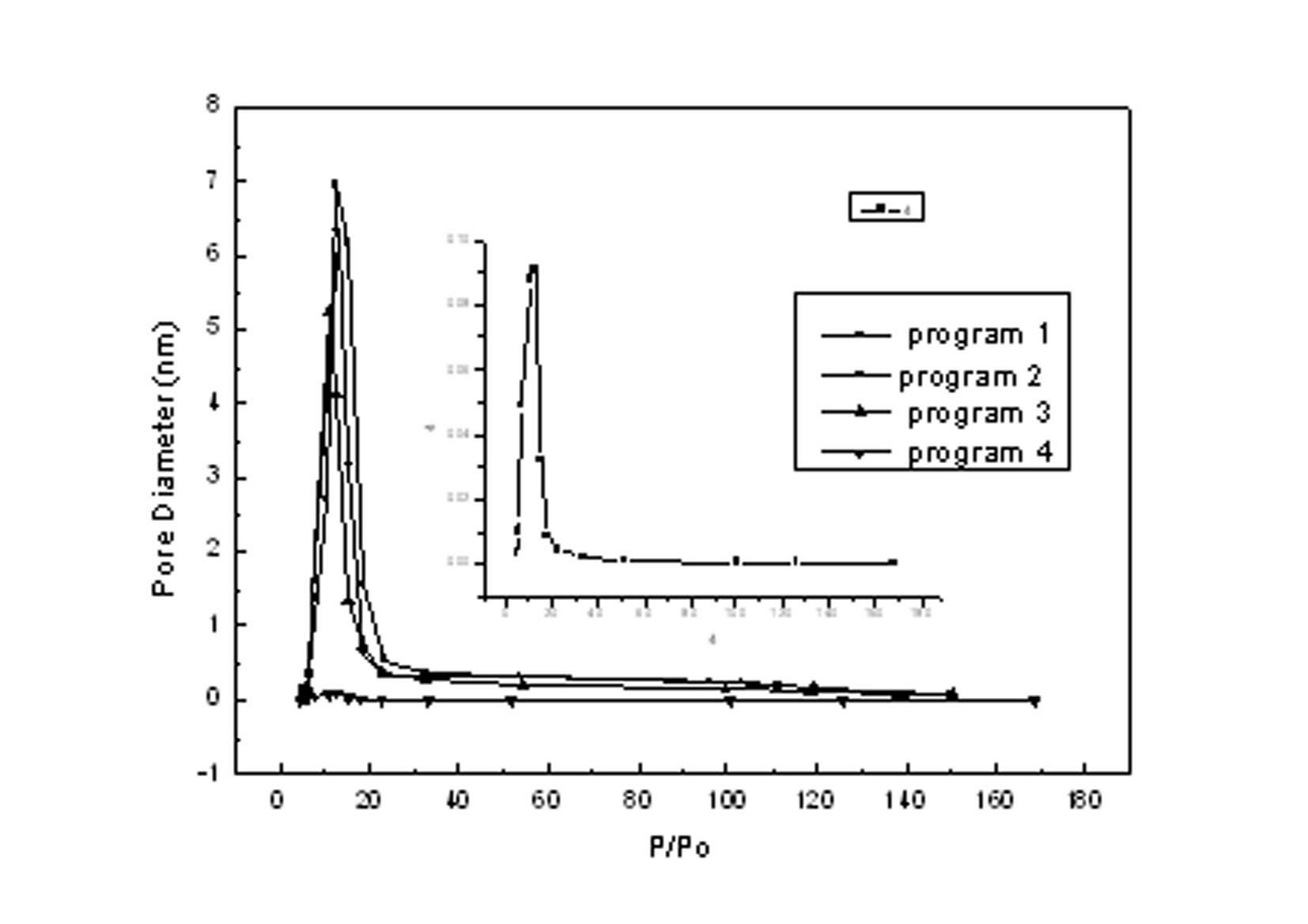

A technology of mesoporous titanium dioxide and template method, applied in the field of solar cells, can solve the problem of small specific surface area of titanium dioxide, and achieve the effect of narrow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 5.34 g of poly(ethylene glycol)-intercalated-poly(propylene glycol)-intercalated-poly(ethylene glycol) (CAS No. 9003-11-6, purchased from Sigma), add 173 mL of deionized water, and then add 61.34 mg Ammonium fluoride (NH4F), 3.974 g trimethylbenzene (TMB), 27.4 mL concentrated HCl (36%, w / w). After stirring for 45 minutes at a temperature of 40° C. and a rotational speed of 300 r / min, 11.74 g of tetraethyl orthosilicate (TEOS) and 4 g of titanium isopropoxide (TTIP) were added to continue stirring for 20 hours. After the reaction, the obtained colloid was transferred into an autoclave, heated in water at 120°C for 20 hours, filtered, and dried at 70°C. When removing the template of the mesoporous material, weigh 1.5g of the above-mentioned dried powder, add 10mL of concentrated nitric acid (HNO 3 ) and 7mL of hydrogen peroxide (H 2 o 2 ), heated in an autoclave at 100°C for 12 hours, filtered, added 10mL of 0.2-40% (mass) HF solution to react for 10 hours, and ...

Embodiment 2

[0035] Weigh poly(ethylene glycol)-intercalated-poly(propylene glycol)-intercalated-poly(ethylene glycol) 5.34g, add 173mL deionized water, add 61.34mg ammonium fluoride (NH 4 F), 3.974 g of trimethylbenzene (TMB), 27.4 mL of concentrated HCl (36%, w / w). After stirring for 45 minutes at a temperature of 40° C. and a rotational speed of 300 r / min, 11.74 g of tetraethyl orthosilicate (TEOS) and 8 g of titanium isopropoxide (TTIP) were added to continue stirring for 26 hours. After the reaction, the obtained colloid was transferred into an autoclave, heated in water at 120°C for 20 hours in a closed state, filtered, and dried at 70°C. When removing the template of the mesoporous material, weigh 1.5g of the above-mentioned dried powder, add 10mL of concentrated nitric acid (HNO 3 ) and 7mL of hydrogen peroxide (H 2 o 2 ), sealed in an autoclave, heated at 100°C for 12 hours, filtered, added 10mL of 0.2-40% HF solution to react for 10 hours, then washed with deionized water unti...

Embodiment 3

[0037] Weigh poly(ethylene glycol)-intercalated-poly(propylene glycol)-intercalated-poly(ethylene glycol) 5.34g, add 173mL deionized water, add 61.34mg ammonium fluoride (NH 4 F), 3.974 g of trimethylbenzene (TMB), 27.4 mL of concentrated HCl (36%, w / w). After stirring for 45 minutes at a temperature of 40° C. and a rotational speed of 300 r / min, 11.74 g of tetraethyl orthosilicate (TEOS) and 12 g of titanium isopropoxide (TTIP) were added to continue stirring for 24 hours. After the reaction, the obtained colloid was transferred into an autoclave, heated in water at 120°C for 20 hours in a closed state, filtered, and dried at 70°C. When removing the template of the mesoporous material, weigh 1.5g of the above-mentioned dried powder, add 10mL of concentrated nitric acid (HNO 3 ) and 7mL of hydrogen peroxide (H 2 o 2 ), sealed in an autoclave, heated at 100°C for 12 hours, filtered, added 10mL of 0.2-40% HF solution to react for 10 hours, then washed with deionized water unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com