Dual-template preparation method of mesoporous TiO2 sphere

A dual-template, mesoporous technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as difficult separation, poor adsorption and photocatalytic performance, and achieve simple preparation and high adsorption performance and good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The mesoporous TiO provided by the embodiment of the present invention 2 The double template preparation method of sphere, this preparation method comprises the following steps:

[0025] Step 1, preparing chitosan acetic acid solution and polyvinyl alcohol aqueous solution respectively;

[0026] Step 2, mixing the above two solutions according to a certain ratio under mechanical stirring at 70±1°C to form a mixed solution;

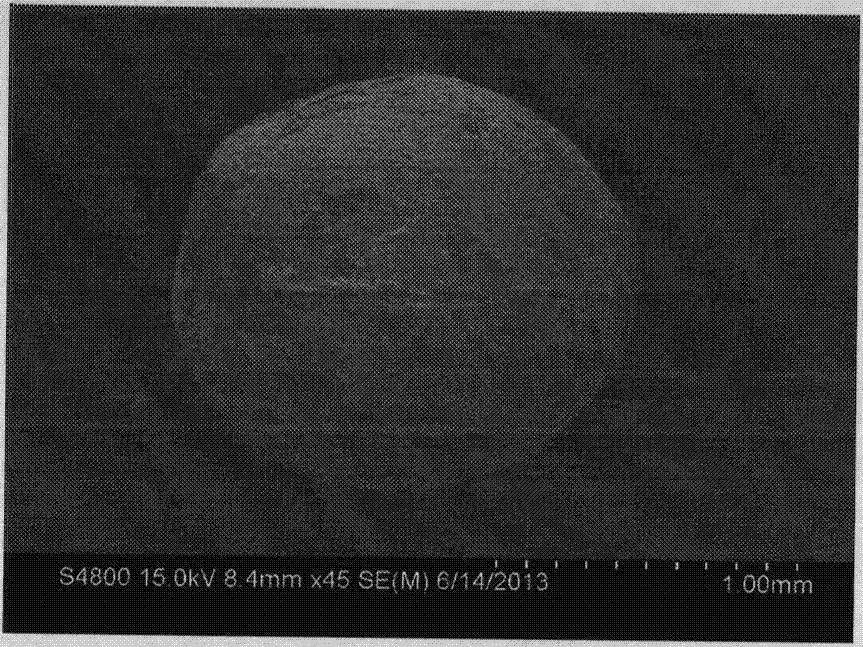

[0027] Step 3, use a syringe to drop the mixed solution into a sodium hydroxide solution with a molar concentration of 0.5M, and instantly form chitosan / PVA hydrogel microspheres with a particle size of 2-3mm;

[0028] Step 4, standing overnight, after being completely solidified, soaking in double distilled water, ethanol, and isopropanol for 30 minutes, and filtering to obtain swollen porous microspheres;

[0029] Step five, soak the chitosan / PVA hydrogel microspheres in the titanium isopropoxide solution for 48 hours at room temperature, the ti...

Embodiment 1

[0048] Dissolve 2g of chitosan powder in 500ml of 5% acetic acid aqueous solution to obtain chitosan acetic acid solution; dissolve 2g of polyvinyl alcohol powder in 50ml of double distilled water, and dissolve under mechanical stirring at 70±1°C, An aqueous solution of polyvinyl alcohol was obtained. The above-mentioned chitosan acetic acid solution and polyvinyl alcohol aqueous solution are mixed according to the volume ratio of 1:1 under mechanical stirring at 70±1° C. to form a mixed solution. Use a syringe with an internal diameter of 0.8mm to drop the mixed solution into 500ml of sodium hydroxide solution with a molar concentration of 0.5M, and instantly form chitosan / PVA hydrogel microspheres with a particle size of 2-3mm; Place overnight, after being completely solidified, soak in double distilled water, ethanol, and isopropanol for 30 minutes, and filter to obtain swollen porous microspheres; at room temperature, chitosan / PVA hydrogel microspheres After soaking in the ...

Embodiment 2

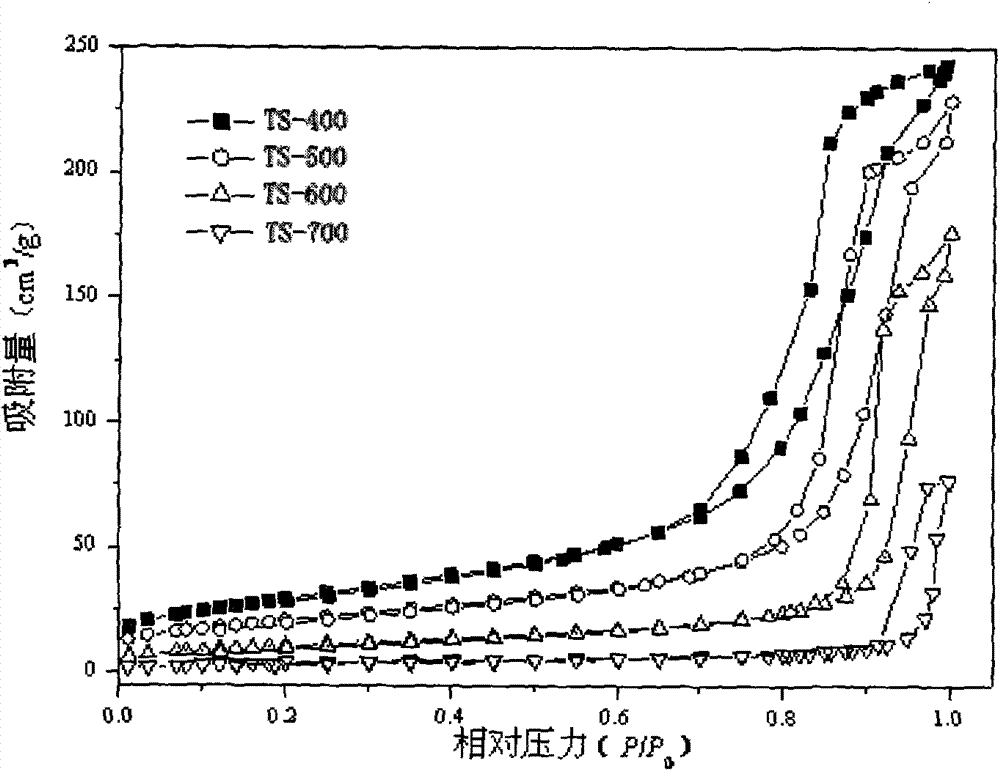

[0050] The difference from Example 1 is that the calcination temperature is 400°C, and the calcined material is marked as TS-400, TiO 2 The pore diameter of the ball is 10.11nm, and the pore volume is 0.376cm 3 / g, indicating that the prepared TiO of TS-400 2 The ball is a mesoporous material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com