Spring steel disc type dynamic vibration absorber with adjustable rigidity

A technology of dynamic vibration absorber and spring steel sheet, which is applied in the direction of spring/shock absorber, spring, shock absorber, etc., can solve the problems that the natural frequency cannot be adjusted from time to time, and the vibration absorption effect is poor, so as to achieve fast frequency change response and increase The support area and the effect of improving the stability of the installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

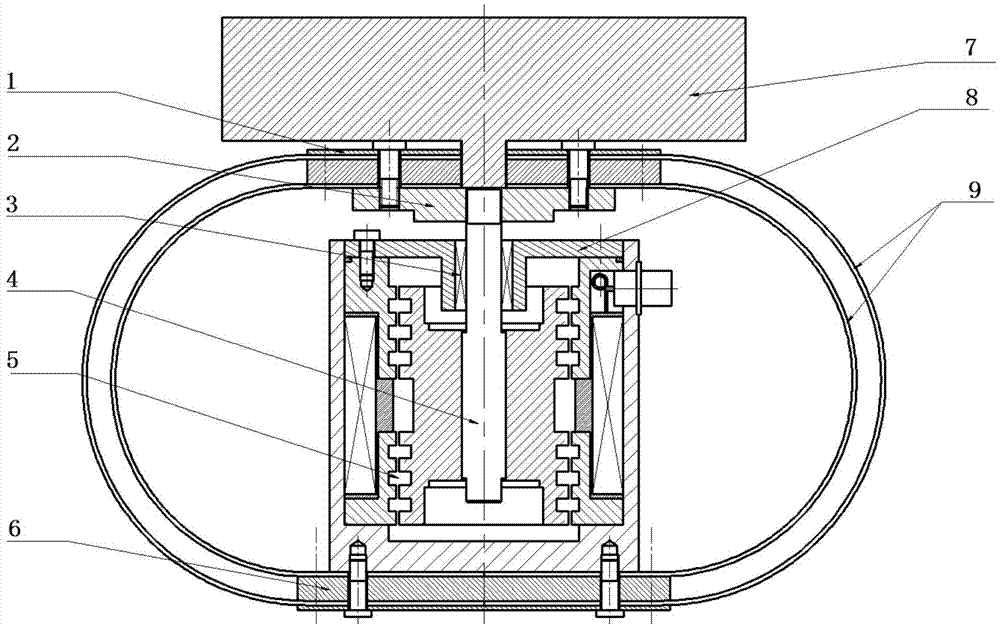

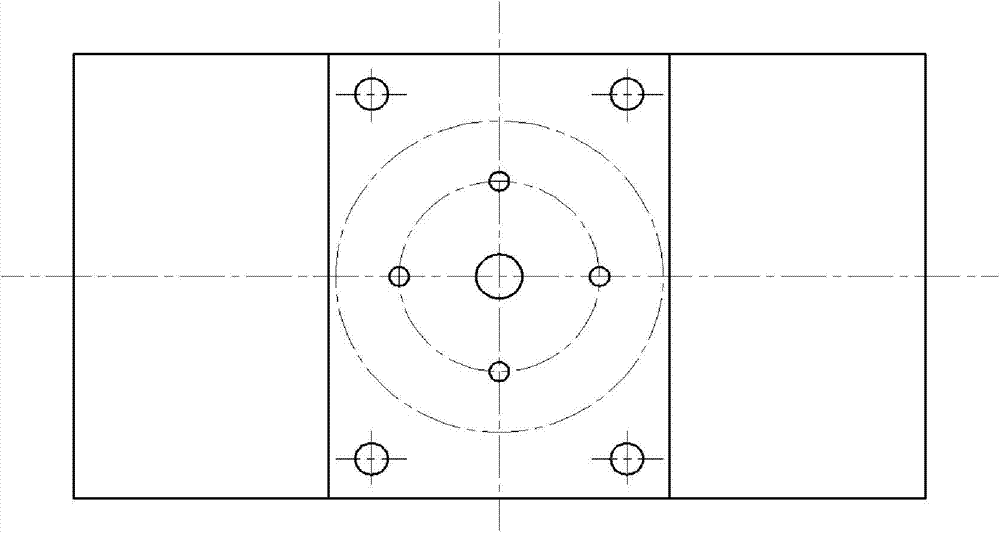

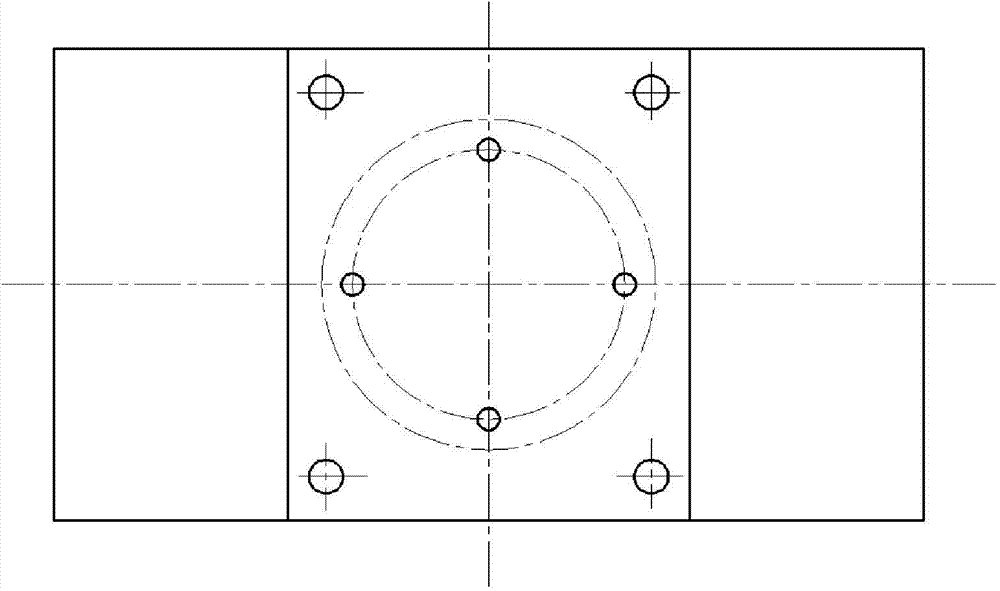

[0019] combine figure 1 The composition of the present invention includes a pressure plate 1, a connecting flange 2, a linear bearing 3, a central shaft 4, an electromagnetic spring part 5, a lining plate 6, a mass block 7, an end cover 8 and a spring steel sheet 9. The spring steel sheet 9 is bent into a certain annular shape as required, and is fixed together with the pressing plate 1 and the lining plate 6 into an annular spring structure. The mass block 7 is installed above the annular spring structure to form a passive mass spring structure. The electromagnetic spring part is placed in the annular spring structure, which together form a stable and reliable shock absorber structure. By changing the current, the electromagnetic stiffness can be changed, and then the overall stiffness can be changed to achieve the purpose of adjusting the working frequency of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com