Methane dry reforming catalyst, preparation method and use of methane dry reforming catalyst and method for preparing synthetic gas through methane dry reforming

A methane dry reforming and catalyst technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as failure to realize industrial application, and achieve catalytic The effect of improving the activity and anti-coke performance and improving the dispersion degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Compared with the prior art, the preparation method of the methane dry reforming catalyst provided by the invention has the advantages of:

[0050] 1. By adding a surfactant to the impregnation solution to reduce the surface tension of water, it is beneficial to the spreading of the impregnation solution on the surface of the carrier, thereby facilitating the dispersion of the metal active component on the surface of the support, and finally making the metal active group in the prepared catalyst The fraction has higher dispersion and smaller grain size.

[0051] 2. It is prepared by the impregnation method, the preparation method is simple, the preparation conditions are easy to accurately control, and the repeatability of the catalyst is very good.

[0052] 3. It is prepared by the impregnation method, so the mechanical strength of the carrier is maintained, and it has high activity and stability no matter in the fluidized bed reactor or in the fixed bed reactor.

[0...

Embodiment 1

[0062] (1) Catalyst preparation

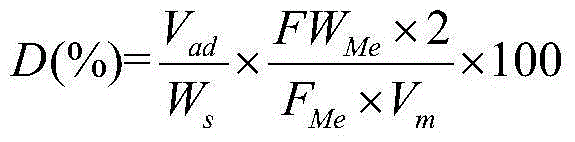

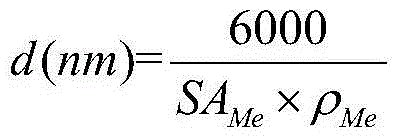

[0063] 1.765g of Ni(NO 3 ) 2 ·6H 2 O was dissolved in 5.6ml of deionized water to obtain a nickel nitrate solution, and after it was dissolved, 0.34g of P123 was added and mixed evenly to obtain an impregnating solution. Take 4g of Al 2 o 3 The carrier is dispersed into the impregnation solution, and after standing for 2 hours, the moisture is evaporated, and then dried in an oven at 120°C for 10 hours. The dried sample was calcined in a muffle furnace at 600°C for 3 hours, and the obtained catalyst was recorded as NiO / Al 2 o 3 -1, the content of the metal active component in terms of metal elements is 8% by weight. The dispersion degree of the metal active component in the catalyst measured by the hydrogen chemical adsorption method is 14.4%, and the average particle diameter of the metal active component is 7.0nm.

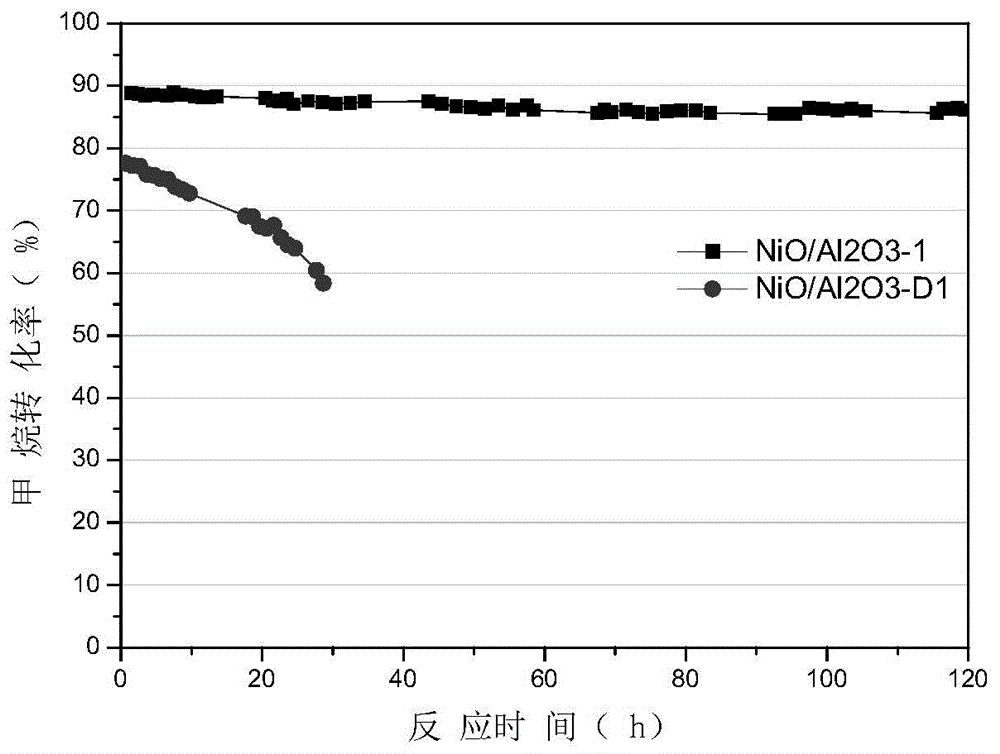

[0064] (2) Catalyst evaluation

[0065] Weigh the above NiO / Al 2 o 3-1 Catalyst 0.1g, diluted to 2ml with 40-60 mesh...

Embodiment 2

[0074] (1) Catalyst preparation

[0075] 1.75g of Co(NO 3 ) 2 ·6H 2 O was dissolved in 4ml of deionized water to obtain an aqueous solution of cobalt nitrate. After the solution was clear, 0.33g of P123 was added, and mixed evenly to obtain an impregnation solution. All the other steps are with the preparation method of corresponding catalyst in embodiment 1, and gained catalyst is denoted as Co 3 o 4 / Al 2 o 3 , the content of the metal active component in terms of metal elements is 8% by weight. The dispersion degree of the metal active components in the catalyst measured by the hydrogen chemical adsorption method is 13.9%, and the average particle diameter of the metal active components is 7.2nm.

[0076] (2) Catalyst evaluation

[0077] Activating the catalyst under the same conditions as in Example 1 and carrying out the methane dry reforming reaction, the reaction was stably carried out after 10 hours and the reaction results were as follows:

[0078] x CH4 =...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com