Molecular sieve loaded BiOX photocatalyst, preparation method and application thereof

A supported catalyst, bismuth oxyhalide technology, applied in the field of photocatalysis, can solve problems such as small specific surface area, and achieve the effect of large specific surface area, which is conducive to large-scale promotion and inhibits agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of Bismuth Oxyfluoride Photocatalyst Supported by SBA-15 Molecular Sieve

[0029] Weigh 4.85 grams of bismuth nitrate and dissolve in 40 mL of ethylene glycol solution, then add 80 mL of ethanol, stir to dissolve, add 0.6 grams of SBA-15, ultrasonically disperse for 0.5 hours, and then stir the suspension for 24 hours; take 0.40 grams of Ammonium fluoride is dissolved in the mixed solution of 40mL ethylene glycol and ethanol, this solution is added dropwise to the above-mentioned suspension and mixed, the ammoniacal liquor diluted with ethanol (V ethanol / V strong ammonia water=10, the mass concentration of strong ammonia water is 25 -28%) to adjust the pH value to 7, and after 12 hours of magnetic stirring, the precipitate was repeatedly washed with deionized water, then put into a 60°C oven for drying, and the powder was roasted at 400°C for 2 hours to obtain a bismuth oxyfluoride-loaded catalyst.

Embodiment 2

[0031] Preparation of Bismuth Oxychloride Photocatalyst Supported by SBA-15 Molecular Sieve

[0032] Weigh 2.43 grams of bismuth nitrate and dissolve in 40 mL of ethylene glycol solution, dissolve 0.276 grams of ammonium chloride in 50 mL of ethanol, dissolve 6 grams of urea in 100 mL of ethanol solution, mix the above three solutions, and stir for 0.5 hours; take 1.2 Add one gram of SBA-15 powder into the above mixed solution, stir at room temperature for 24 hours, ultrasonically treat the obtained suspension for 4 hours, filter the obtained product, wash with deionized water to remove excess ions, and dry at 80°C to obtain Supported catalyst containing bismuth oxychloride.

[0033] According to the above steps, by changing the added amount of the carrier, supported catalysts with different ratios of Bi / Si were prepared respectively.

[0034] Changing the carrier, using ZSM-5 and HY molecular sieve as the carrier, the preparation method is the same as the above steps, and th...

Embodiment 3

[0036] Catalyst performance evaluation and physical property characterization results

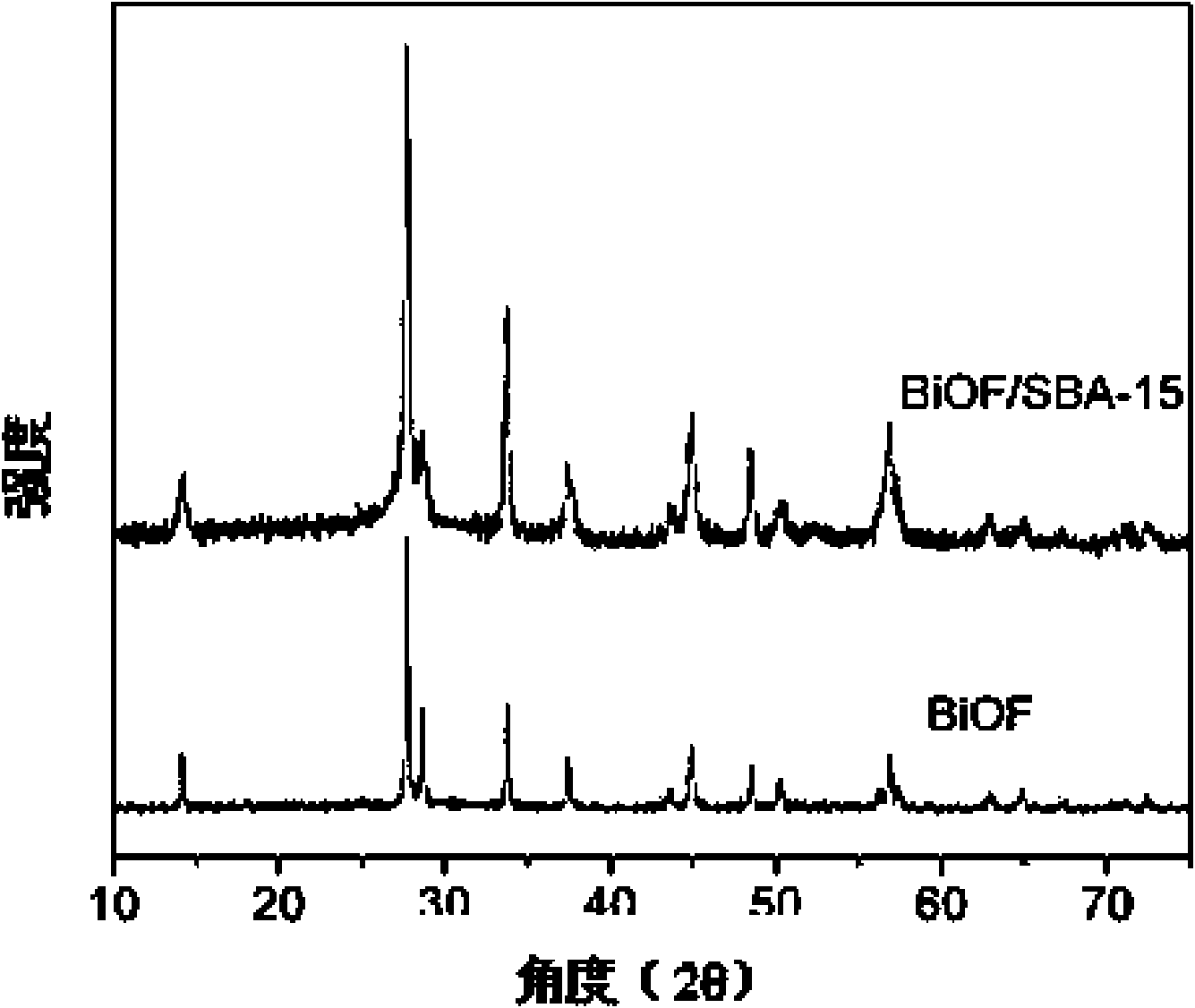

[0037] The performance evaluation of the catalysts prepared in Examples 1 and 2 for catalytic oxidation of benzene was carried out in a continuous flow reactor. The catalyst is packed in the reaction tube, the catalyst dosage is 0.4g, the catalyst particle size is 50-70 mesh, the reaction gas flow rate is about 20mL / min, and the initial concentration of benzene is 230ppm. Using Agilent 6890D gas chromatograph to regularly analyze C6H6 and CO in the atmosphere 2 concentration, TCD and FID are detectors, the average conversion rate of benzene and the amount of carbon dioxide generated, the data are listed in Table 1 and Table 2 respectively; Table 3 is the specific surface area and crystallinity grain size. figure 1 is the XRD test result of BiOF and BiOF / SBA-15 (Bi / Si=1:1). The activity test results showed that the activity of bismuth oxyhalide to degrade benzene was significantly improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com