Array-type novel high-performance eddy current damper

An eddy current damper, eddy current damping technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc. The application of eddy current damper and other issues can achieve the effect of saving resources, compact structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

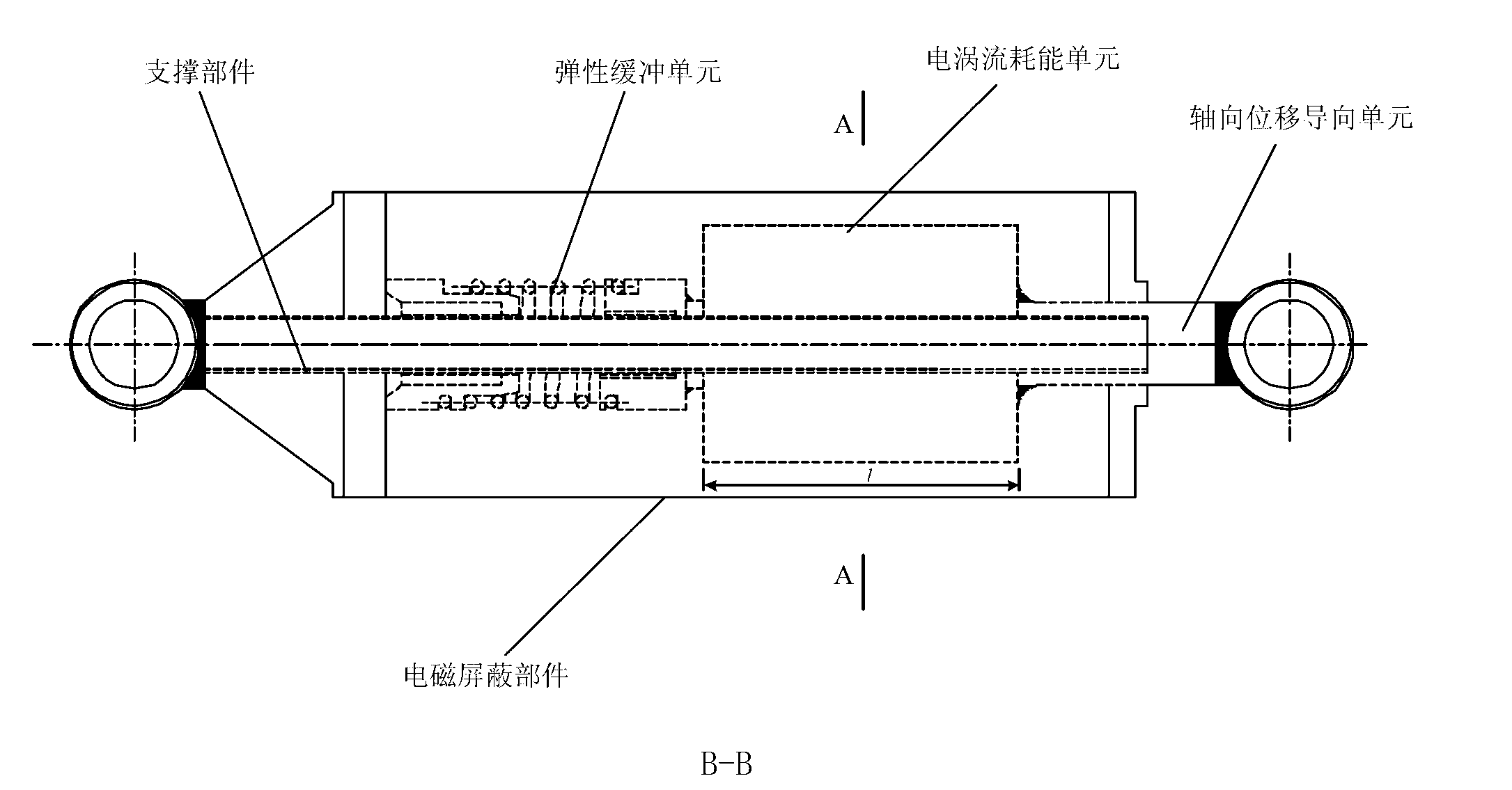

[0040] In the following description, the present invention will be described in detail based on exemplary embodiments.

[0041] Note that the same reference numerals are used for the same elements and descriptions are not repeated.

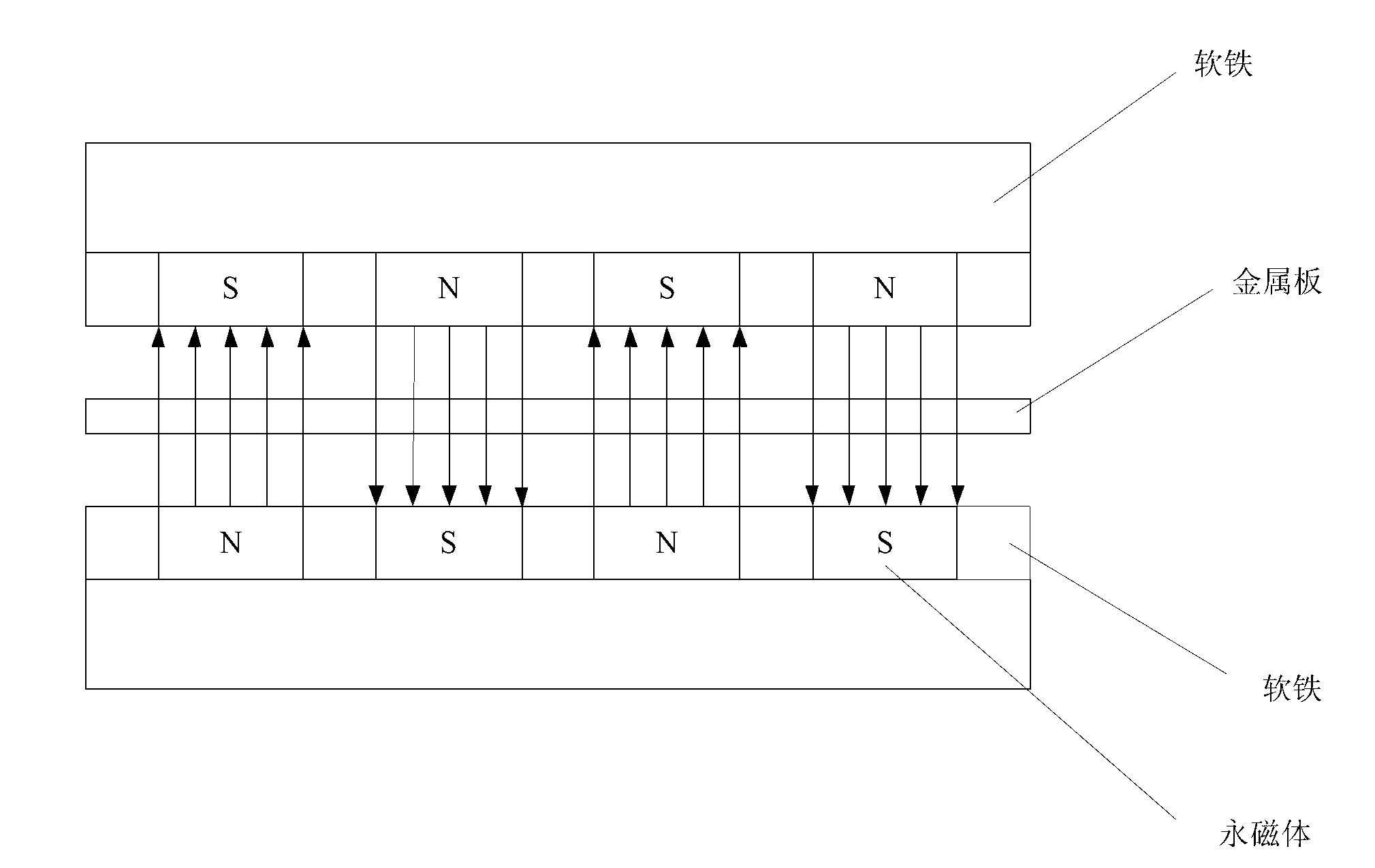

[0042] Such as figure 1 As shown, two rows of permanent magnets and soft iron are arranged alternately, and the direction of the magnetic field of the permanent magnets changes alternately, so a uniform and constant magnetic field with alternating directions is formed in the gap between the two. When the vibration is input, the metal plate unit inside the damper is driven to cut the magnetic field generated by the permanent magnet, so an eddy current is generated on the surface of the metal plate unit.

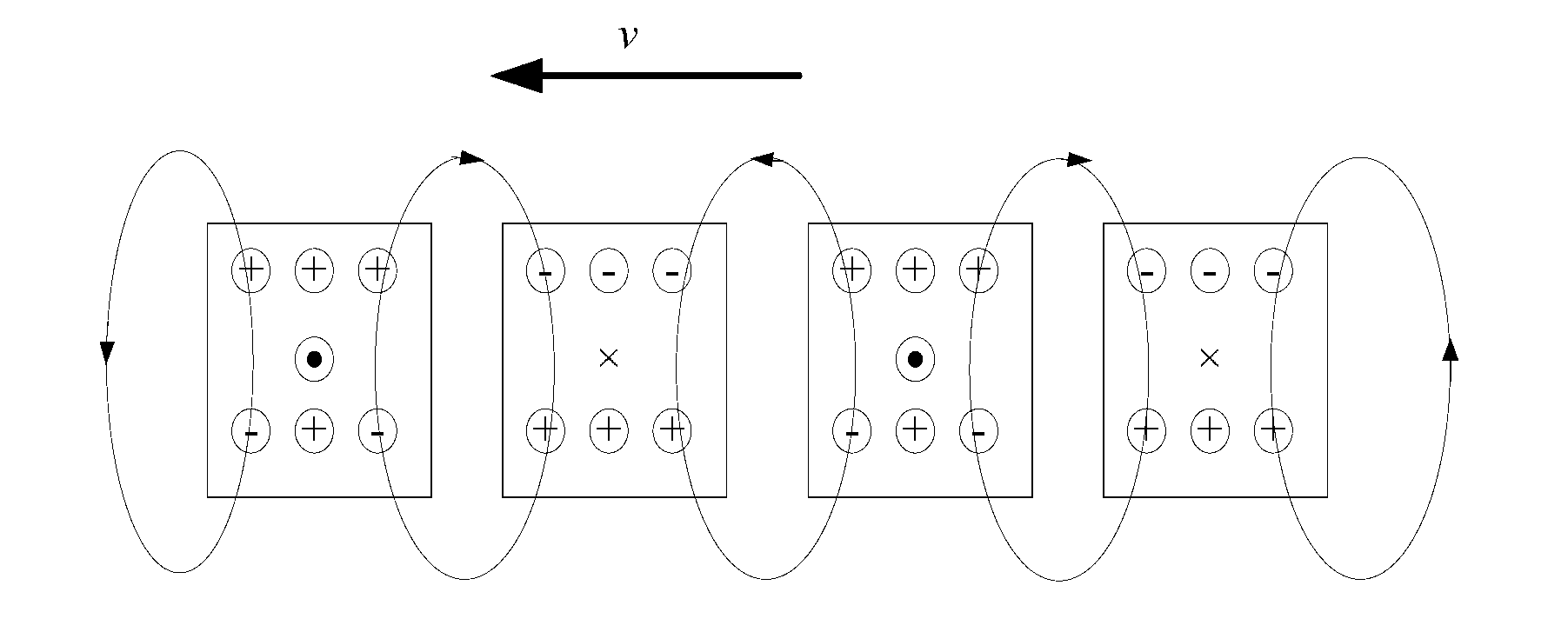

[0043] Such as figure 2 As shown, when the magnetic field where the conductor is located changes alternately in its moving direction, a corresponding number of eddy currents will be formed inside it. Compared with the structural scheme with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com