Nano silver colloid aqueous solution preparation method using sodium cellulose glycolate

A technology of sodium carboxymethyl cellulose and aqueous solution, which is applied in the fields of medical sterilization, metal optoelectronics and catalytic nano-functional material synthesis, can solve the problem of unknown molecular weight range of sodium carboxymethyl cellulose, uneven product particle size and shape, and cost. Control simplicity and lack of consideration, to achieve the effect of easy regulation of particle size distribution, convenience for large-scale industrial production, and realization of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

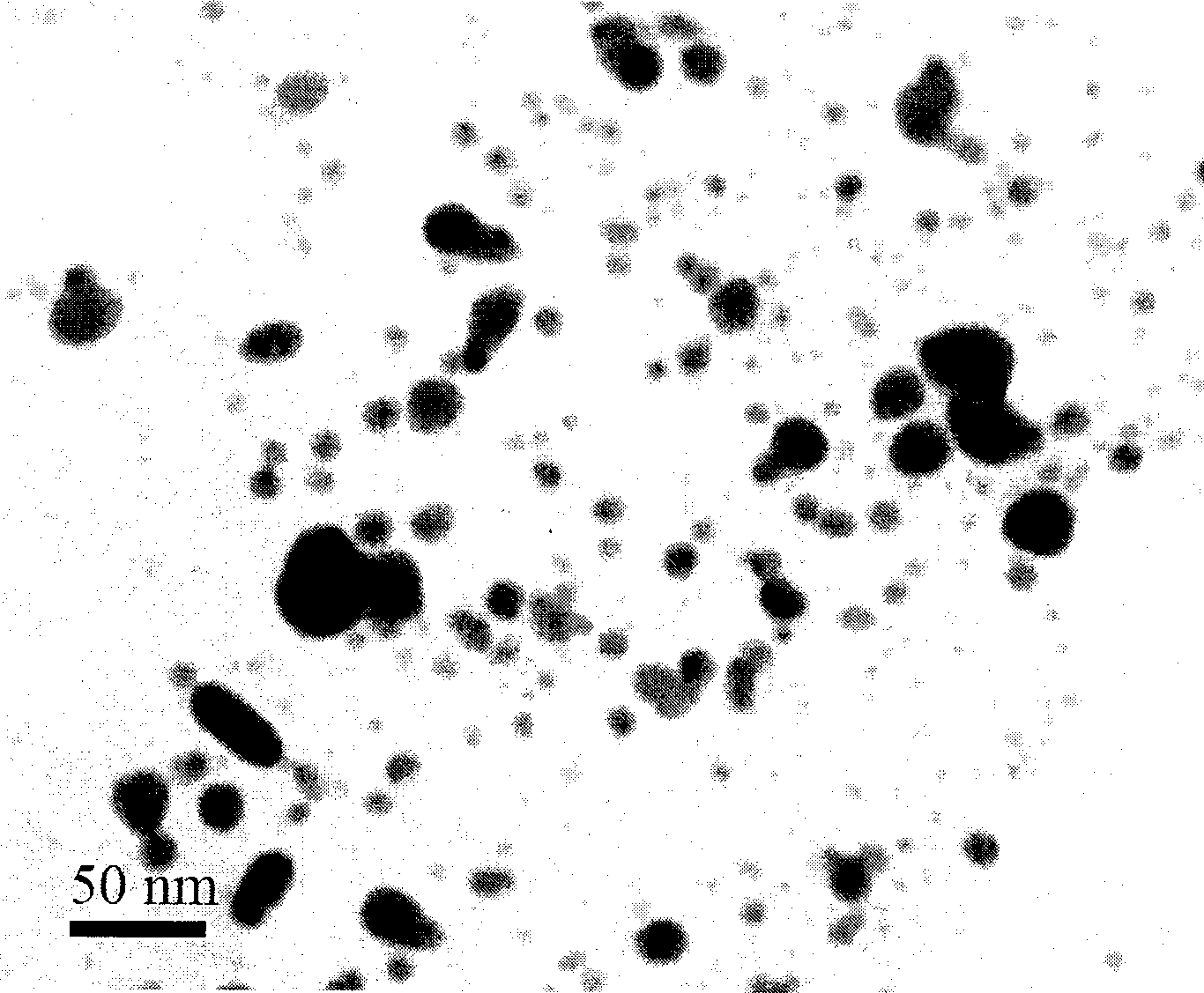

[0018] Add 0.34g of silver nitrate to 10mL of deionized water to make solution A; add 0.012g of reducing agent and protective agent sodium carboxymethylcellulose (Mw≈90,000) into 20mL of deionized water to dissolve, and adjust the pH value at 9- 11 to prepare solution B; take 0.1mL of solution A and add it to solution B, and react at 15°C for 20 hours to obtain a light yellow silver colloidal aqueous solution. The results of transmission electron microscopy are shown in the attached figure 1 As shown, the average particle size of the obtained silver nanoparticles is less than 60nm.

Embodiment 2

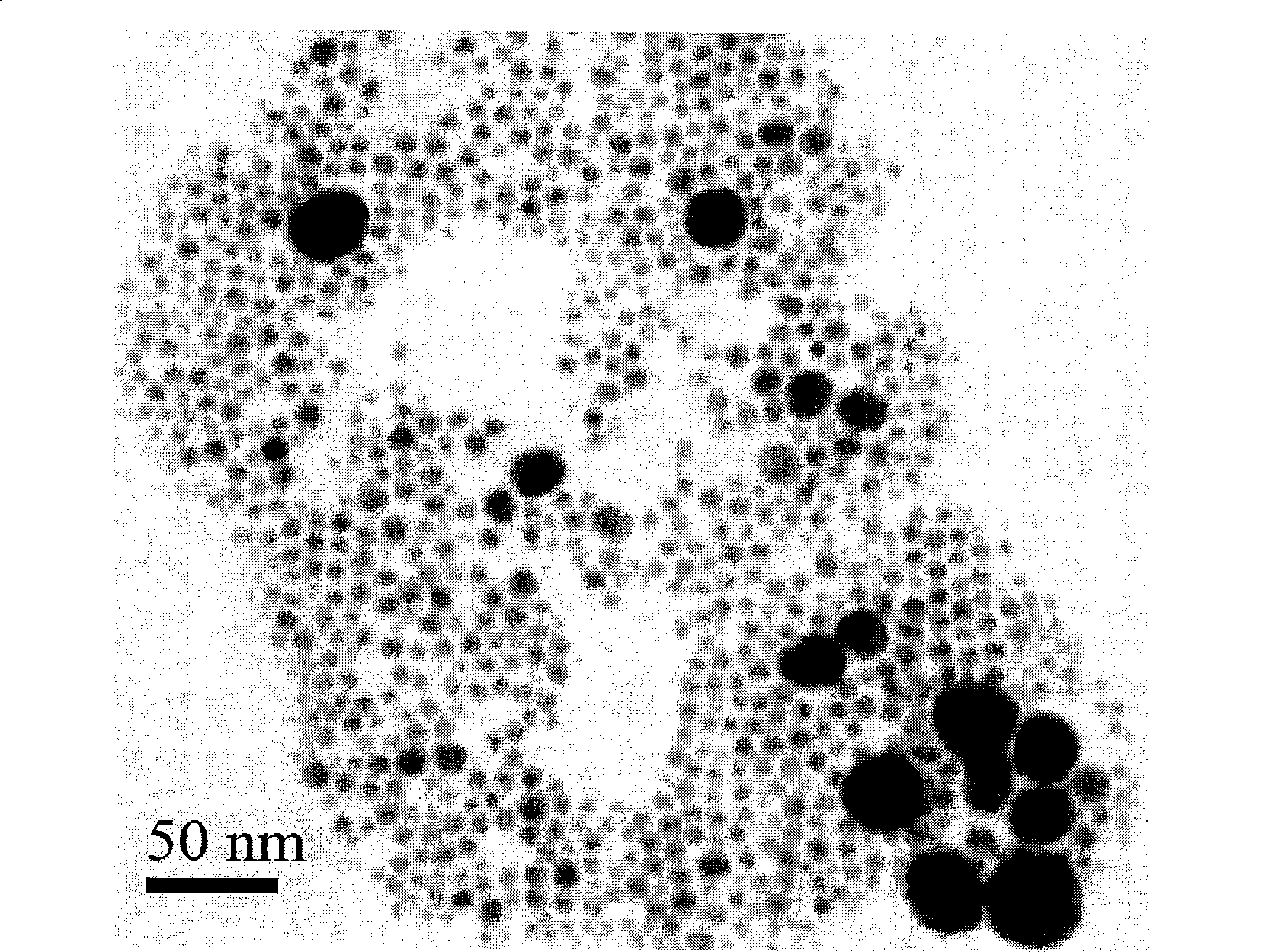

[0020] Add 0.34g of silver nitrate to 10mL of deionized water to make solution A; add 0.012g of reducing agent and protective agent sodium carboxymethyl cellulose (Mw≈90,000) into 20mL of deionized water, stir thoroughly for 30min (speed 200r / min) after dissolving, adjust the pH value between 7-9 to make solution B; take 0.1mL of solution A and add it to solution B, place it in a water bath and heat it to 60°C; continue to stir and react for 4 hours to obtain yellow nano Silver colloid aqueous solution, transmission electron microscopy results as attached figure 2 As shown, the average particle size of the obtained nano-silver particles is less than 100 nanometers.

Embodiment 3

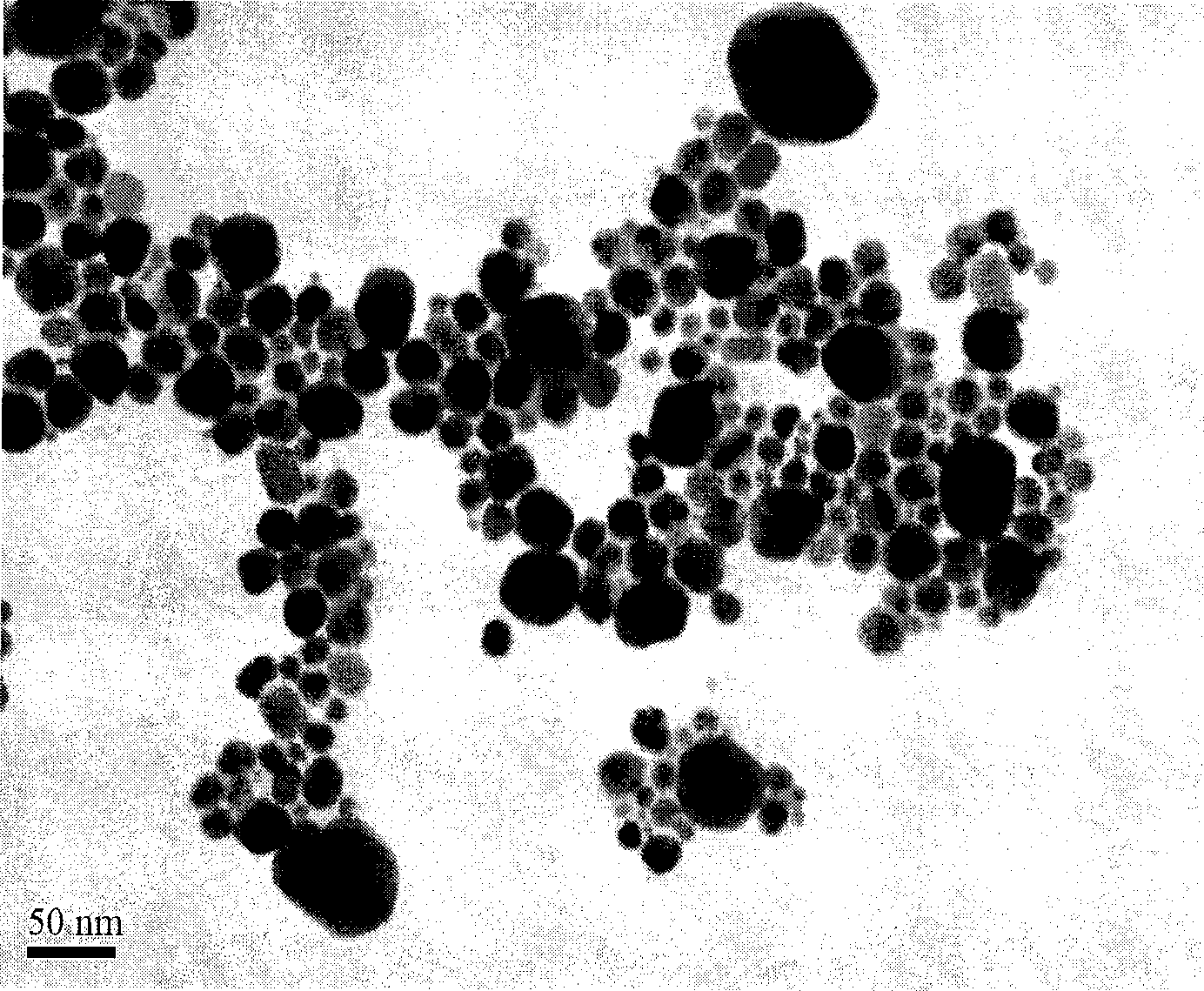

[0022] Add 0.34g of silver nitrate into 10mL of deionized water to prepare liquid A; add 0.004g of reducing agent and protective agent sodium carboxymethyl cellulose (Mw≈90,000) into 20mL of deionized water, stir thoroughly for 30min (speed 100r / min ) after dissolving, adjust the pH value between 7-9 to make solution B; take 0.1mL of solution A and add it to solution B, place it in a water bath and heat it to 80°C; continue to stir and react for 4 hours to obtain yellow nano-silver Sol aqueous solution, transmission electron microscopy results are as attached image 3 As shown, the average particle diameter of the obtained silver nanoparticles is about 30 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com