Palladium-free chemical copper plating method

A technology of electroless copper plating and inorganic materials, applied in the field of electroless plating, can solve the problems of slow reaction speed and precipitation of copper particles, and achieve the effects of low cost, stable plating solution, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

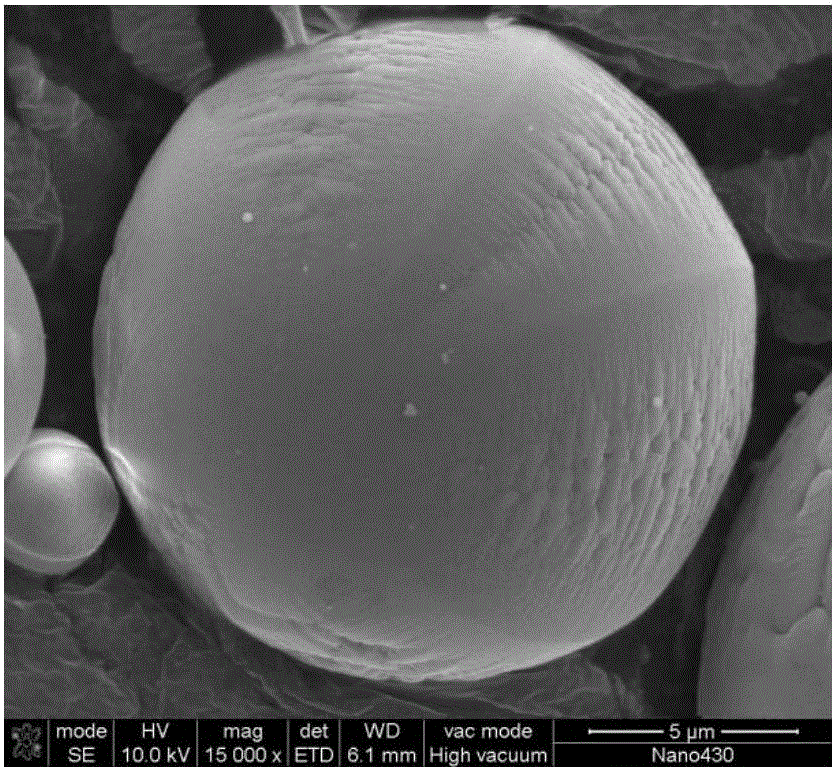

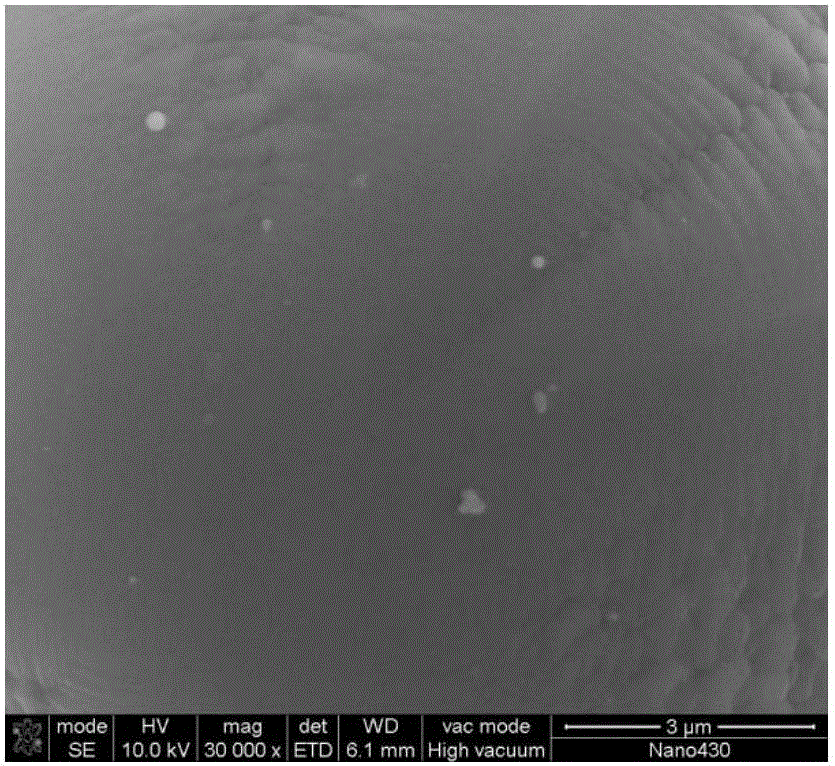

[0041] (1) Sonicate the alumina microspheres with an average particle size of 10 μm in absolute ethanol for 20 minutes, filter, collect the filter cake, and air-dry at 110°C for 4 hours before use;

[0042] (2) Use tris (trishydroxymethylaminomethane) and hydrochloric acid to prepare a buffer solution with a pH of 8.5, use the buffer solution to prepare a dopamine solution with a concentration of 2.7g / L, take 50mL of the dopamine solution, and add 2g of pretreated alumina Microspheres, stirred in the air atmosphere for 24 hours, filtered, collected filter cakes, vacuum-dried at 60°C for 4 hours, dopamine-coated alumina microspheres, set aside;

[0043] (3) Prepare a 17g / L silver nitrate solution complexed with ammonia water, disperse the dopamine-coated alumina microspheres in the silver nitrate solution complexed with ammonia water, stir for 2 hours, filter, wash 4 times with deionized water, and collect The filter cake was dried in a vacuum drying oven at 40°C for 6 hours to...

Embodiment 2

[0048] (1) Soak chopped carbon fibers with an average diameter of 8 μm and a length of 4 mm in aqua regia solution to remove the glue, wash them with deionized water for 5 times, and then dry them with air at 80°C;

[0049] (2) Use tris (trishydroxymethylaminomethane) and hydrochloric acid to prepare a buffer solution with a pH of 8.0, use the buffer solution to prepare a dopamine solution with a concentration of 5g / L, take 50mL of dopamine solution, and add 1g of pretreated chopped carbon fiber , stirred in the air atmosphere for 12 hours, filtered, collected the filter cake, vacuum-dried at 70°C for 4 hours, and then dopamine-coated chopped carbon fibers were used for later use;

[0050] (3) Prepare a 3g / L silver nitrate solution, place the dopamine-coated chopped carbon fiber in the silver nitrate solution, stir for 1 hour, filter, wash 4 times with deionized water, collect the filter cake, and dry it in a vacuum oven at 40°C for 5 hours reserve;

[0051] (4) Configure an ...

Embodiment 3

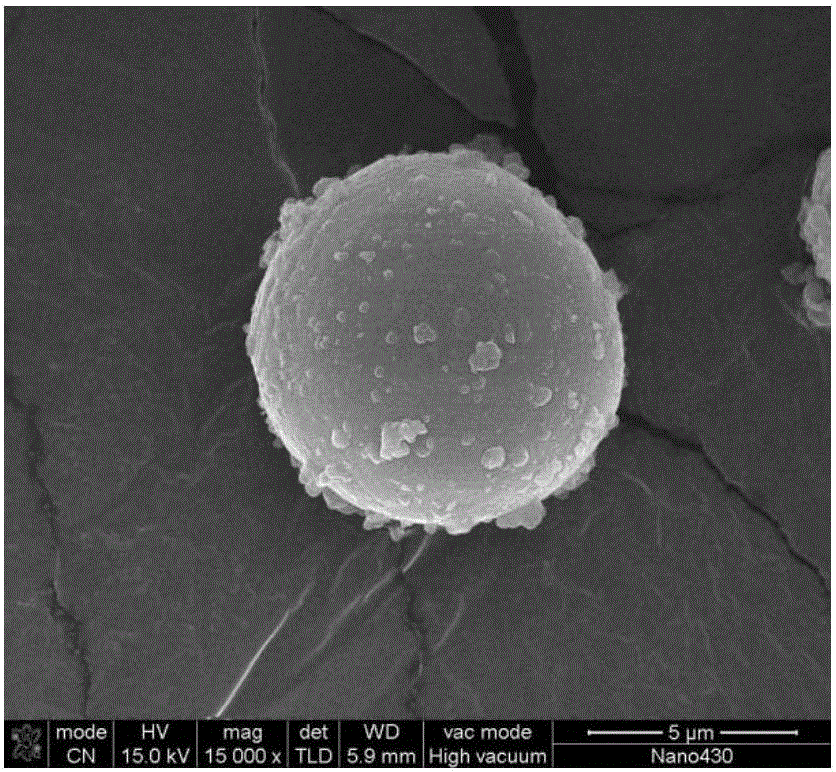

[0055] (1) Put the hollow glass microspheres with an average particle size of 12 μm in absolute ethanol for ultrasonication, and let them stand until they are separated. Take the hollow glass microspheres in the upper layer, filter them, collect the filter cake, and air-dry them at 80°C for 6 hours. reserve;

[0056] (2) Use tris and hydrochloric acid to prepare a buffer solution with a pH of 8.5, use the buffer solution to prepare a dopamine solution with a concentration of 0.5g / L, take 50mL of dopamine solution, add 1g of pretreated hollow glass microspheres, and stir in the air atmosphere 24h, filter, collect the filter cake, vacuum-dry at 40°C for 5h, and then dopamine-coated hollow glass microspheres, set aside;

[0057] (3) Prepare a 3g / L silver nitrate solution complexed with ammonia water, place dopamine-coated hollow glass microspheres in the silver nitrate solution complexed with ammonia water and stir for 4 hours, filter, wash 4 times with deionized water, and colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com