Cyanide-free gold plating method for preparing ACF (anisotropic conductive film) conductive gold spheres

A technology of cyanide-free gold plating and conductive gold balls, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems affecting the social safety of operators, less adsorption amount, easy to decompose, etc., and achieves wide application Foreground, improvement of binding force, effect of large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

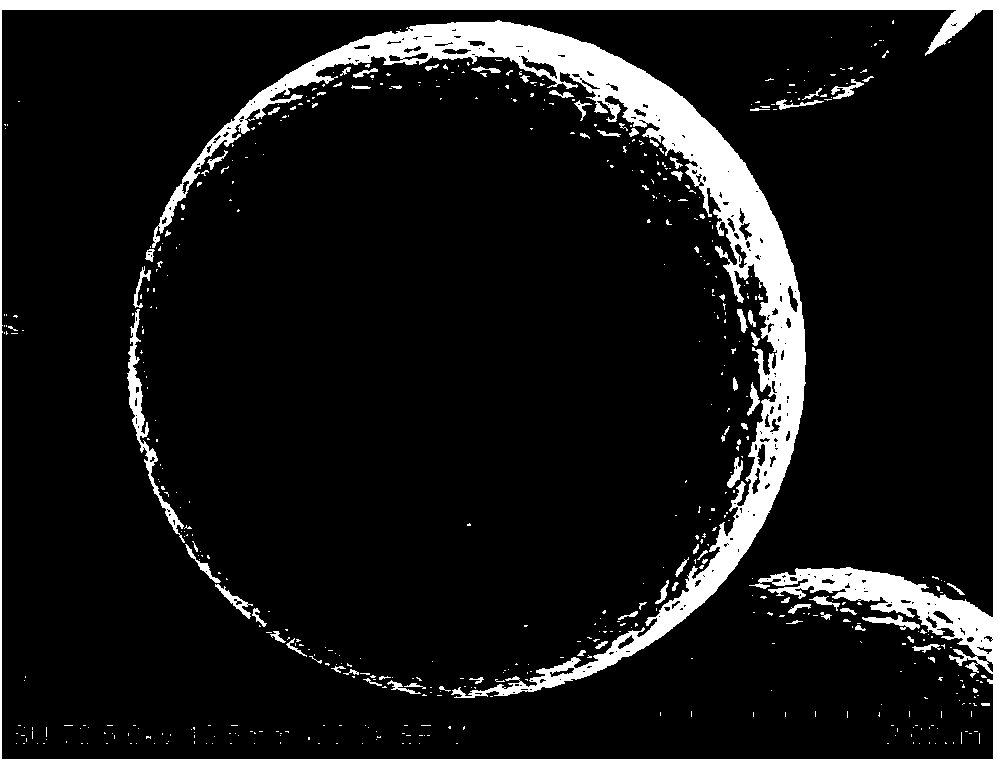

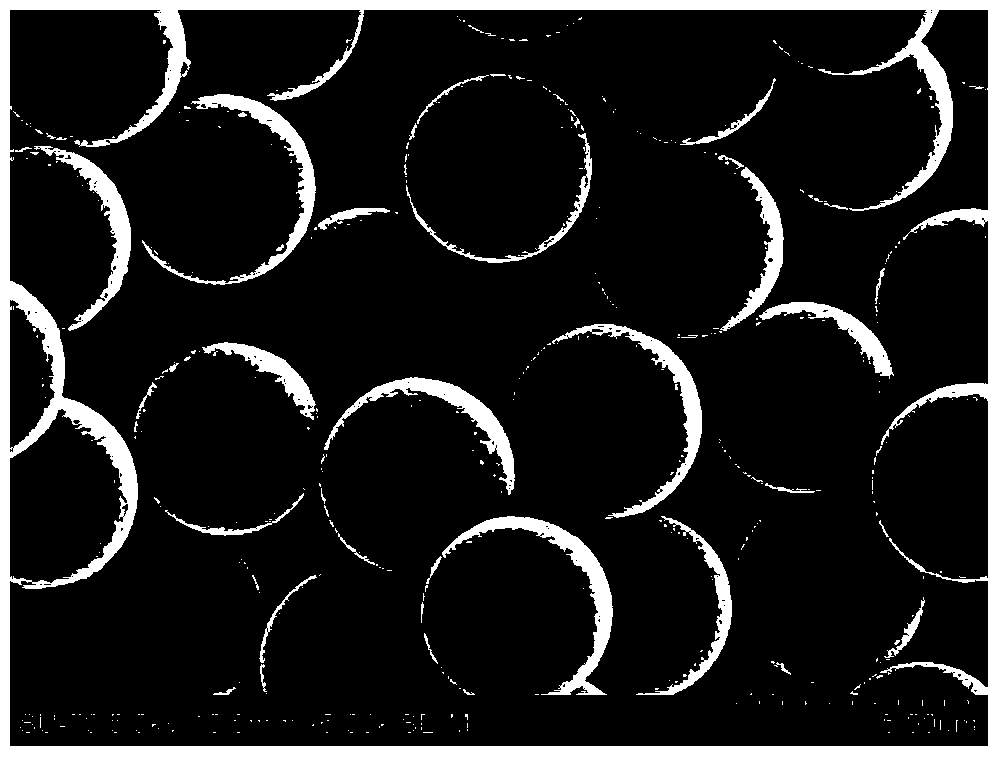

Embodiment 1

[0049] Add 20 g of polystyrene microspheres and 20 g of dichloroethane into a three-necked bottle equipped with a stirrer, ultrasonically disperse, stir and swell at 300 rpm for 1 hour, and obtain swollen polystyrene microspheres. Add 20g of methylal to a three-necked flask equipped with a stirrer, a dropping funnel, a thermometer, and a condenser with a calcium chloride drying tube, and add 35g of sulfuryl chloride dropwise within 1 hour at 25°C. , and then reacted for 1 hour to obtain the reacted mixed solution. Pour the mixed solution into the swollen polystyrene microspheres, stir at 300 rpm for 3 hours, then add 8 g of anhydrous zinc chloride powder into the reaction system, and stir at 40° C. for 8 hours. Centrifuge and wash to obtain chloromethylated polystyrene microspheres. The chloromethylated polystyrene microsphere of gained is joined in the three-neck bottle that the NaOH solution of 100ml 5% is housed, in Bu 4 Under the condition that NOH is used as a catalyst,...

Embodiment 2

[0053] Ultrasonic dispersion of 25 g of polystyrene microspheres in 25 g of dichloroethane was then added to a three-necked bottle equipped with a stirrer, and stirred and swelled at 300 rpm for 1 hour to obtain swollen polystyrene microspheres. In a three-necked flask equipped with a stirrer, a dropping funnel, a thermometer and a condenser tube equipped with a calcium chloride drying tube, add 22g of methylal, and drop 39g of sulfuryl chloride within 1 hour at 25°C. , and then reacted for 1 hour to obtain the reacted mixed solution. The mixture was poured into the swollen polystyrene microspheres and stirred at 300 rpm for 3 hours. Then add 10 g of anhydrous zinc chloride powder into the above reaction system, and stir at 40° C. for 8 hours. Centrifuge and wash to obtain chloromethylated polystyrene microspheres. The chloromethylated polystyrene microsphere of gained is joined in the three-neck bottle that the NaOH solution of 150ml 5% is housed, in Bu 4 Under the con...

Embodiment 3

[0057] Ultrasonic dispersion of 30 g of polystyrene microspheres in 30 g of dichloroethane was added to a three-necked bottle equipped with a stirrer, and stirred and swelled at 300 rpm for 1 hour to obtain swollen polystyrene microspheres. Add 25g of methylal to a three-necked flask equipped with a stirrer, a dropping funnel, a thermometer, and a condenser with a calcium chloride drying tube, and add 45g of sulfuryl chloride dropwise within 1 hour at 25°C. , and then reacted for 1 hour to obtain the reacted mixed solution. Pour the mixed solution into the swollen polystyrene microspheres, stir at 300 rpm for 3 hours, then add 12 g of anhydrous zinc chloride powder into the reaction system, and stir at 40° C. for 8 hours. Centrifuge and wash to obtain chloromethylated polystyrene microspheres. The chloromethylated polystyrene microsphere of gained is joined in the three-neck bottle that 200ml 10% NaOH solution is housed, in Bu 4 Under the condition that NOH is used as ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com