Gel immobilization enzyme with catalytic and antibacterial functions and preparation method thereof

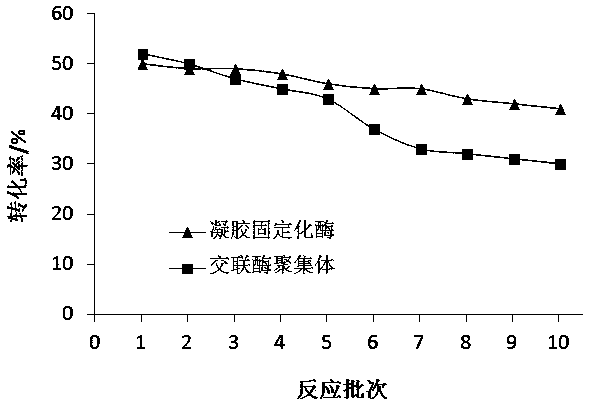

A technology of immobilizing enzymes and gels, which is applied to the direction of immobilization on or in inorganic carriers, or in or on organic carriers, which can solve the problems of limited application, difficult recycling, and easy contamination of bacteria, etc., and achieve the goal of overcoming Poor mechanical stability, easy to use continuously, and the effect of solving the problem of bacterial contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation of cross-linked enzyme aggregates can refer to [Schoevaart R, Wolbers M W, GolubovicM, Ottens M, Kieboom A P, van Rantwijk F, van der Wielen L A, Sheldon R A. Preparation, optimization, and structures of cross-linked enzyme aggregates (CLEAs). Biotechnology and Bioengineering, 2004, 87(6):754-762.]. Among them, enzymes include but are not limited to protease, penicillin acylase, urease, pectinase, lactase, trehalose synthase, glucose isomerase, glycosidase, amylase, pullulanase, glucose oxidase, peroxidase Hydrogenase, laccase, phytase, organophosphate hydrolase, etc. or a combination thereof.

[0018] Polymers capable of forming gels include, but are not limited to, gelatin, pectin, agar, polyvinyl alcohol, sodium alginate, carrageenan, konjac gum, chitosan, dextran, polyacrylamide, silica gel, and the like. Only one kind of polymer can be used, or two or more kinds of polymers can be blended for use. The polymer is pre-dissolved before use. For exam...

Embodiment 1

[0024] In this embodiment, the enzyme used is trehalose synthase, the polymer used is chitosan, and the nanoparticles with antibacterial function used are nano Ag.

[0025] Use 50mmol / L, pH7.0 phosphate buffer to prepare 5mL trehalose synthase solution, the protein content of which is 5mg / mL, add glucose to the enzyme solution to make the final concentration of glucose 2% (w / v), gradually add 1.2g of PEG 6000, after the PEG is dissolved, add glutaraldehyde, the final concentration of glutaraldehyde is 0.2% (v / v), mix well, then cross-link at 25°C for 2h, then centrifuge at 3000r / min for 20min, The resulting precipitate was centrifuged and washed three times with 10 mmol / L, pH 7.0 phosphate buffer solution to obtain cross-linked enzyme aggregates of trehalose synthase, which were suspended in 5 mL of water for later use.

[0026] Add silver nitrate solution to the chitosan solution prepared by acetic acid solution, the final concentration of chitosan is 1% (w / v), the final conc...

Embodiment 2

[0029] The preparation method is the same as in Example 1, except that 0.02 g of Fe is added to the resulting 4 mL mixture. 3 o 4 Magnetic powder, the resulting gel-immobilized enzyme can be separated and recovered by using an external magnetic field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com